Insulation plate forming apparatus

A technology of forming equipment and thermal insulation board, which is applied in the field of presses, can solve the problems of limited thickness and shorten the maintenance time, and achieve the effects of not easy to crack, shorten the maintenance time, and reduce the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

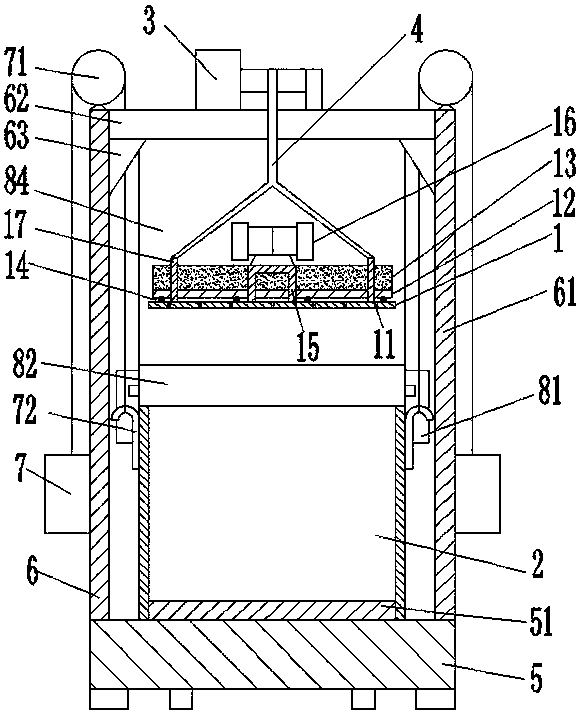

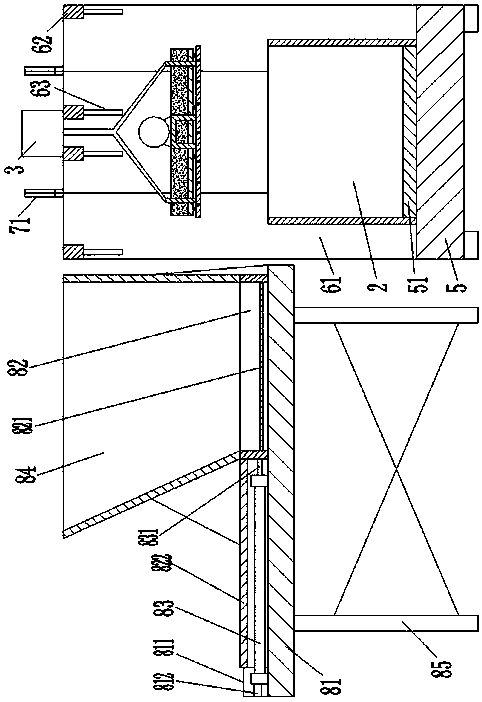

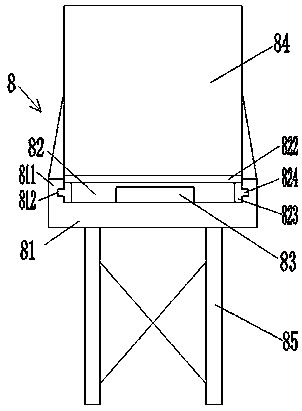

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] see figure 1 , figure 2 , the thermal insulation board molding equipment of specific embodiment, comprise pressing mechanism and feeding mechanism 8, and pressing mechanism comprises base 5 and the mold box body 2 of upper and lower end opening, and the upper surface of described base 5 is convexly provided with positioning platform 51, and base 5 and the positioning platform 51 can be an integral structure, or can be fixedly connected by welding. In this embodiment, a positioning platform 51 is welded and fixed on the base 5; the mold box 2 is placed on the upper surface of the base 5 and the The positioning platform 51 is covered inside it, and the height of the positioning platform 51 protruding from the upper surface of the base 5 is less than the depth of the mold box 2, and the outer contour shape of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com