An integrated internally supported hub motor electric wheel-

An in-wheel motor, support technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of reducing the weight of electric wheels, tire deflation, etc., and achieve the effect of reducing weight, improving heat dissipation performance, and convenient and quick replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solutions of the present invention, the specific implementation manners will be described below in conjunction with the accompanying drawings, and the invention will be further described in detail.

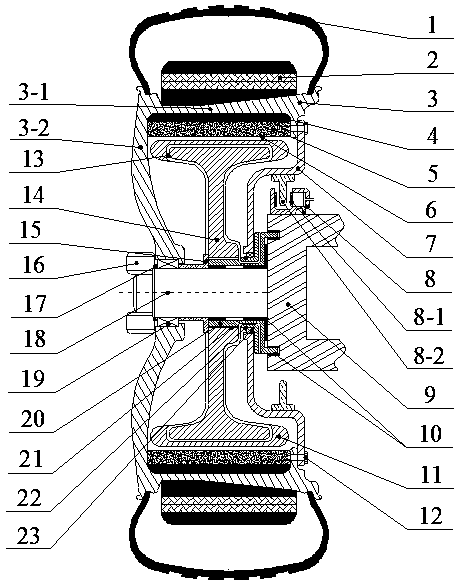

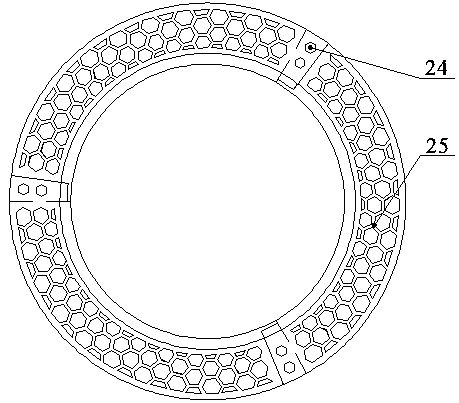

[0017] Such as figure 1 The shown integrated internally supported in-wheel motor electric wheel includes a tire 1, a hub 3, an in-wheel motor, a honeycomb structure inner support 2, a brake 8 and a vibration damping mechanism, and the described in-wheel motor includes an integrated hub 3 and a brake The shell that connects the disc 7, the outer rotor composed of the rotor yoke 4 and the permanent magnet 5, the inner stator 11, and the stator support frame 14; the hub 3 is a closed spoke 3 with a petal-shaped groove -2 and a rim 3-1 with a connecting disc structure, the special wheel hub is supported on the wheel support shaft through the bearing 19; Integrated housing, the brake connecting disc 7 is supported on the suspension sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com