Calcium carbide transport line and calcium carbide trolleys

A transportation line and calcium carbide technology, which is applied in the field of calcium carbide transportation lines and calcium carbide trolleys, can solve problems such as inflexible steering of calcium carbide trolleys, reduce track radius, and reduce production costs, so as to reduce assembly tasks, reduce steering radius, and avoid rollover accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

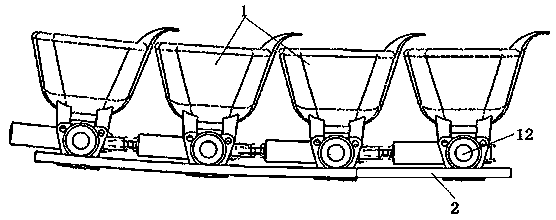

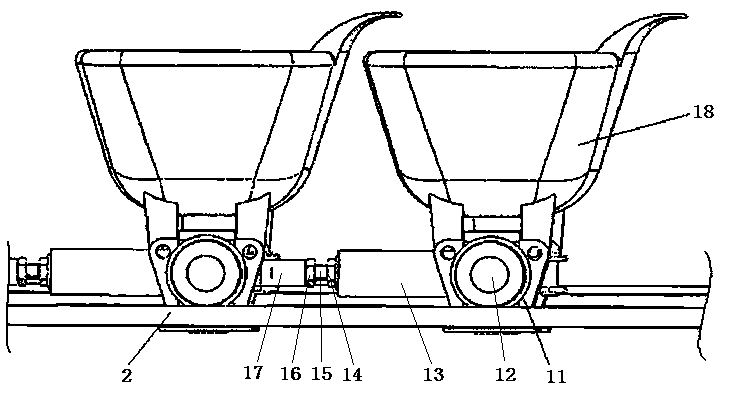

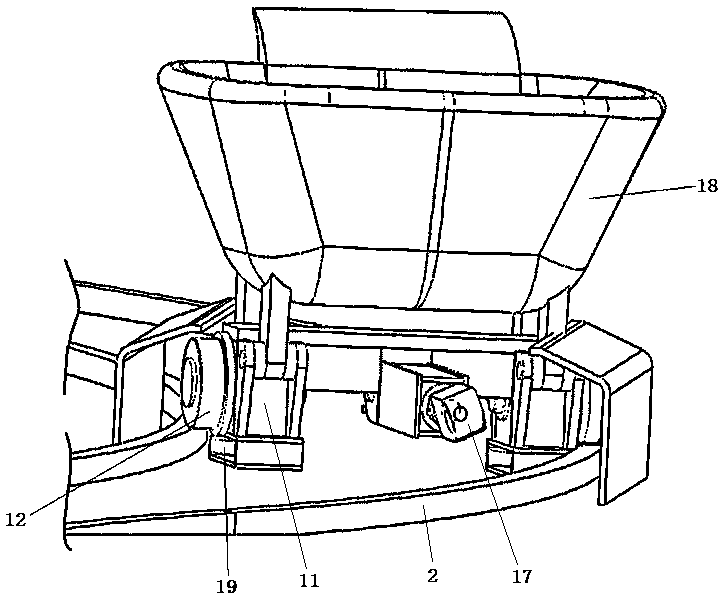

[0037] Now in conjunction with the accompanying drawings, the specific implementations of the calcium carbide transport line and the calcium carbide trolley in the present invention are described: as figure 1 As shown, the calcium carbide transportation line is composed of two parts, which are the conveying track 2 arranged around the calcium carbide furnace and the calcium carbide trolley 1 arranged on the conveying track 2 . Wherein, the conveying track 2 is a closed-loop structure, formed by two guide rails arranged side by side, and an overturning part capable of turning the calcium carbide trolley 1 over to realize unloading is also arranged in the conveying track 2 . The adjacent calcium carbide trolleys 1 are connected to form a closed-loop train through corresponding structures, which can drive the calcium carbide in molten state to cool. Between the calcium carbide trolley 1 and the conveying track 2, there is an anti-rollover structure for preventing the calcium carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com