System and method for LNG (liquefied natural gas) regasification and fresh water preparation of LNG power ship

A preparation system and regasification technology, applied in chemical instruments and methods, fresh water production devices, auxiliary equipment, etc., can solve the problems of not explaining in detail how to prepare fresh water, insufficient utilization of heat, insufficient utilization of heat, etc. , to achieve the effect of improving comprehensive utilization efficiency, improving energy utilization rate, and reducing the loss of cold energy and heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

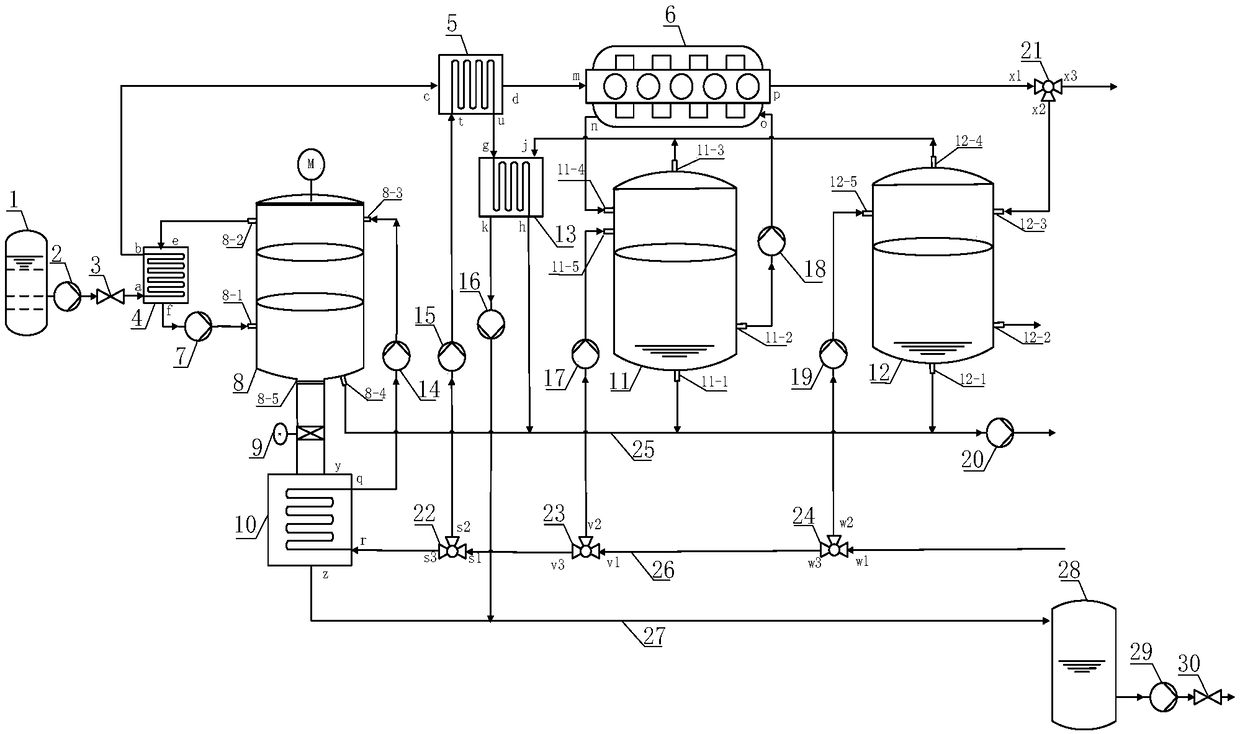

[0028] Combine below figure 1 And specific embodiment the patent invention is described in further detail.

[0029] Such as figure 1 Shown: a kind of LNG power ship LNG regasification and fresh water preparation system of the present invention, comprises LNG regasification system and fresh water preparation system; system. The LNG regasification system is sequentially composed of a liquid storage tank 1, a booster pump 2, a low-temperature gate valve 3, a low-temperature heat exchanger 4, a condensation heat exchanger 5, and a fuel inlet m of the main engine 6 connected through pipelines; the fresh water preparation system , wherein, the frozen fresh water system is sequentially passed by the cryogenic heat exchanger 4 outlet f, the circulation pump 7, the refrigerant inlet joint 8-1 of the crystallizer 8, the refrigerant outlet joint 8-2, and the cryogenic heat exchanger 4 inlet e. Pipeline connection structure; the ice crystal outlet joint 8-5 of the crystallizer 8 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com