Release paper for food baking

A release paper and food technology, applied in special paper, textiles, papermaking, paper, etc., can solve the problems affecting product taste and shape, uneven heating at the bottom of food, waste of materials and product shape, etc., to improve product taste and appearance Aesthetics, improved appearance integrity, weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

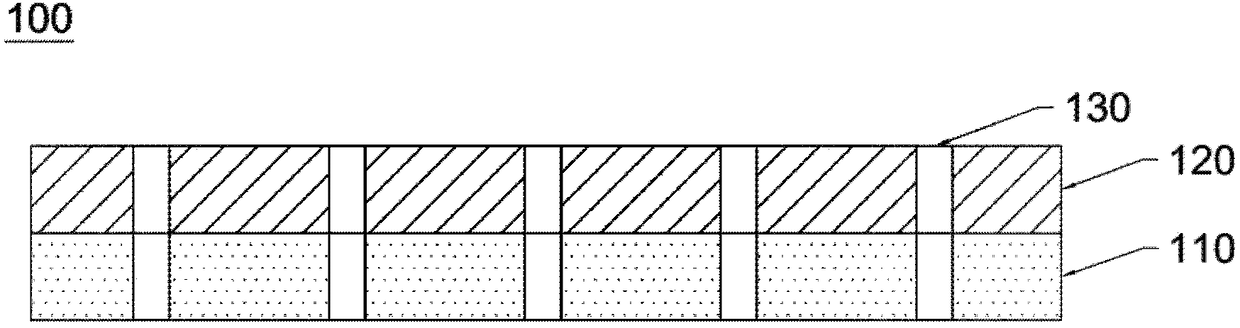

[0052] figure 1 It is a cross-sectional view of a release paper for food baking according to the first embodiment of the present invention.

[0053] Such as figure 1 As shown, according to an embodiment of the present invention, a release paper 100 for food baking is provided, including a base paper layer 110 and a release layer 120; wherein the release layer 120 is formed by curing a water-based release agent.

[0054] The optional material for the backing paper layer 110 is high-density paper, which can prevent the release agent from penetrating into the backing paper layer 110 to a certain extent, so as to prevent the problems of poor curing of the release agent and excessive dosage of the release agent. For example, you can choose High-density matt paper or high-density wood pulp paper, etc.

[0055] When the backing paper layer 110 has a higher density, the release layer 120 can be directly arranged on the backing paper layer 110; A coating layer may be provided betwee...

no. 2 example

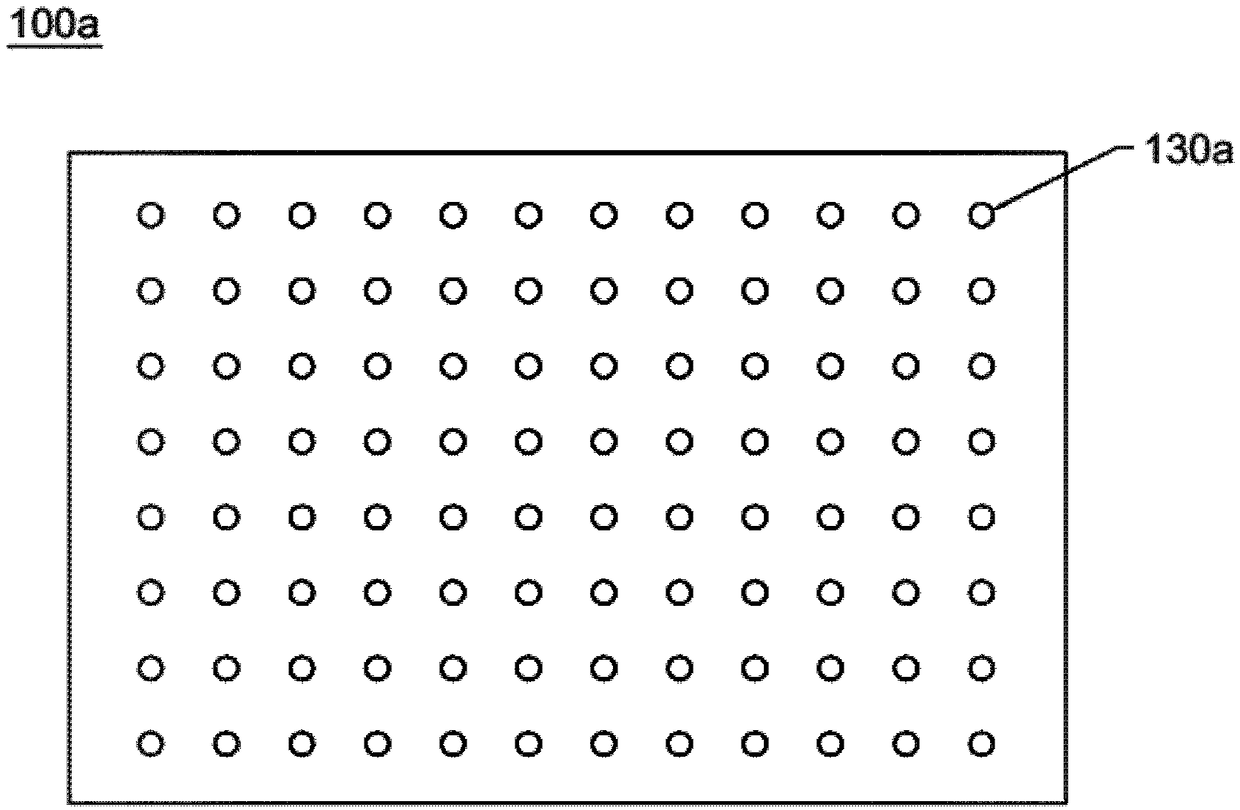

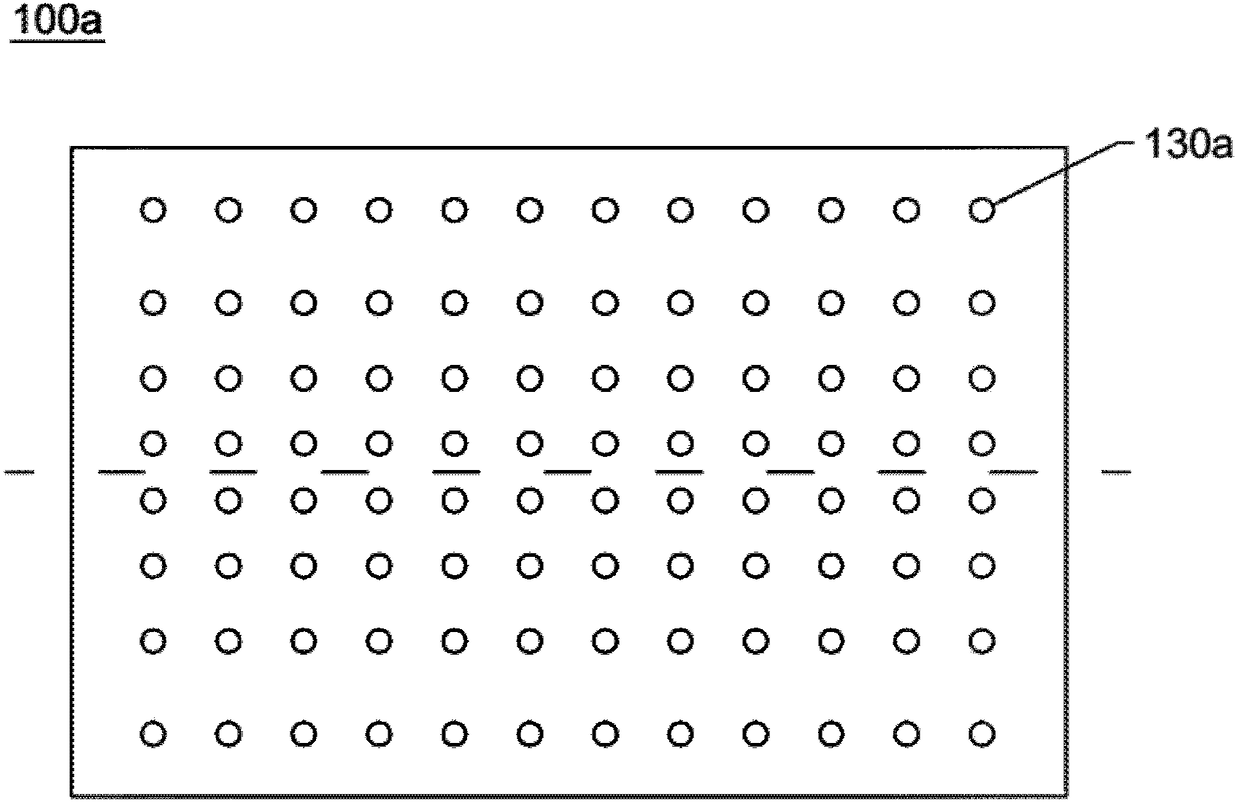

[0065] figure 2 It is a top view of the release paper for food baking according to the second embodiment of the present invention; image 3 It is a top view of a release paper for food baking according to another optional implementation of the second embodiment of the present invention; Figure 4 It is a top view of a release paper for food baking according to yet another optional implementation of the second embodiment of the present invention.

[0066] Such as figure 2 As shown, in some optional embodiments of the present invention, the air holes 130a are uniformly arranged to ensure that the food is evenly heated during the baking process. It should be noted that the air holes 130a in this embodiment include the actual use range of the release paper 100a, and the air holes 130a may not be provided for areas such as the edge of the release paper that are not in contact with food in actual use.

[0067] The meaning of "uniform" in this embodiment is not limited to for ex...

no. 3 example

[0069] Figure 5 is a top view of a release paper for food baking according to a third embodiment of the present invention, Figure 6 It is a top view of a release paper for food baking according to another optional implementation of the third embodiment of the present invention.

[0070] Such as Figure 5 As shown, in some optional embodiments of the present invention, the release paper 100b is provided with a selected area 140b; the diameter of the air hole 130b located in the selected area 140b is larger than that located outside the selected area 140b The diameter of the pores 130b; or, the distribution of the pores located in the selected area is denser than the distribution of the pores located outside the selected area. In the process of food baking, water vapor can easily and evenly penetrate from the top and side of the food near the surface of the food, especially the part near the top and side of the food, so as to achieve uniform heating; but inside the food, esp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com