Release film for polaroid

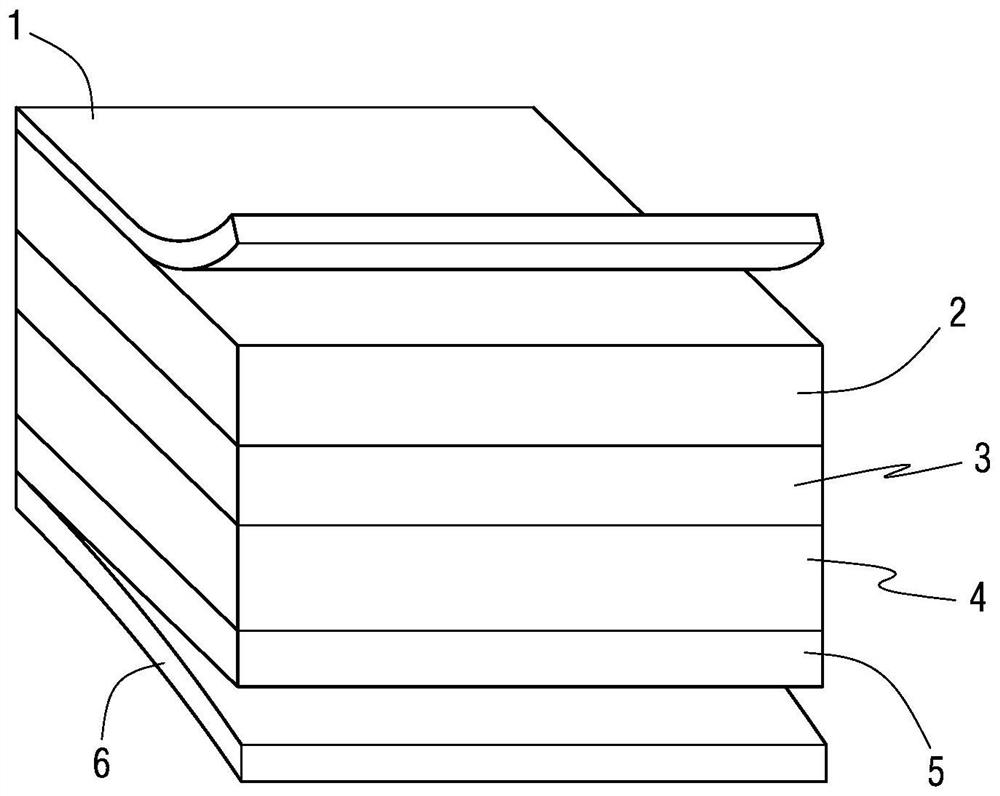

A release film and polarizer technology, applied in the field of polarizers, to achieve high adhesion, excellent release performance, and prevent the PAS glue from being pulled up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] With the polybutadiene polyurethane of 60 weight parts, the polyacrylate resin of 45 weight parts, the hydroxypropyl methacrylate of 10 weight parts, the trifluoroethyl methacrylate reactive monomer diluent of 25 weight parts, 25 weight parts Parts of octadecyl methacrylate active monomer diluent are uniformly mixed, adding 1 part by weight of initiator is 2-hydroxyl-2-methyl-1-phenyl-1-propanone, and magnetically stirred for 120 seconds to obtain Release agent.

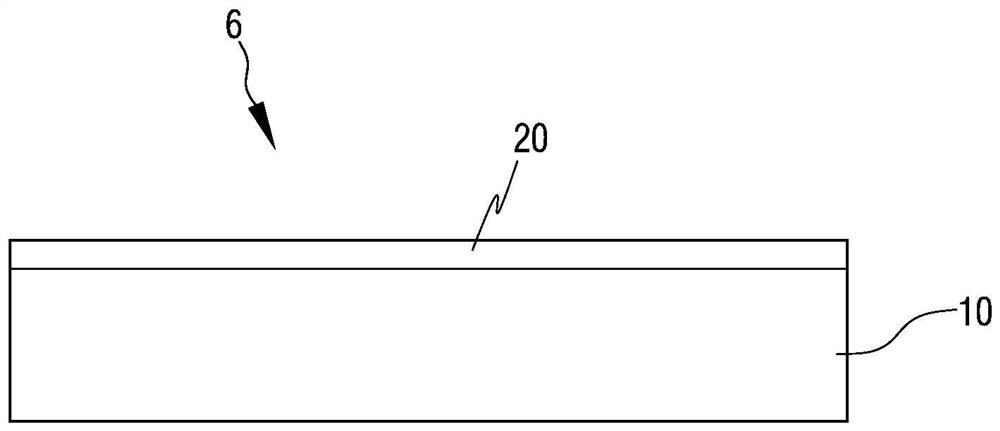

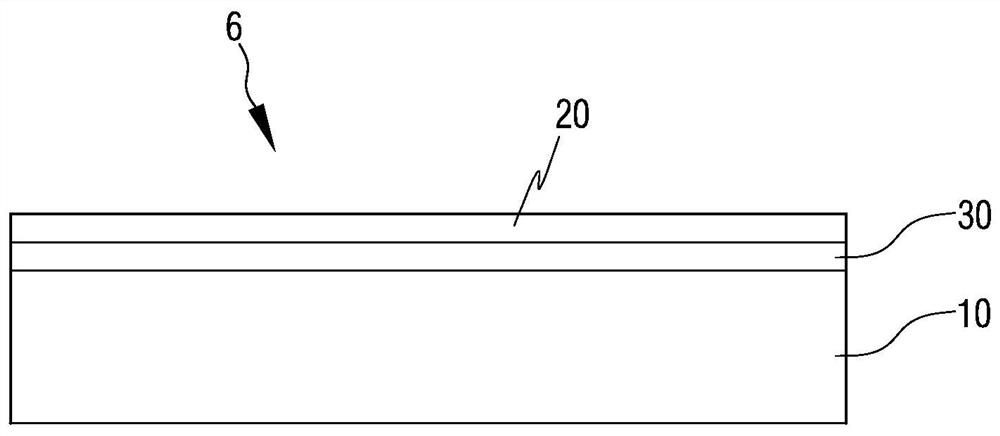

[0028] The release agent is evenly coated on the surface of the PET release film substrate 10 with a thickness of 39 μm, vacuum defoaming for 1 hour, N 2 The release agent layer 20 was formed after being cured by ultraviolet light irradiation for 180 seconds under certain conditions, and the thickness of the release agent layer 20 was measured to be 5 μm.

[0029] After testing, the release agent layer 20 of this embodiment has good stability below 150°C, without decomposition and detachment, and still has co...

Embodiment 2

[0033] With the polybutadiene polyurethane of 140 weight parts, the polyacrylate resin of 85 weight parts, the hydroxypropyl methacrylate of 25 weight parts, the trifluoroethyl methacrylate reactive monomer diluent of 55 weight parts, 55 weight parts Parts of octadecyl methacrylate active monomer diluent are uniformly mixed, adding 5 parts by weight of the initiator is 2-hydroxyl-2-methyl-1-phenyl-1-acetone, and magnetically stirred for 120 seconds to obtain Release agent.

[0034] The release agent is evenly coated on the surface of the PET release film substrate 10 with a thickness of 55 μm, vacuum defoaming for 1 hour, N2 The release agent layer 20 was formed after being cured by ultraviolet light irradiation for 180 seconds under certain conditions, and the thickness of the release agent layer 20 was measured to be 10 μm.

[0035] After testing, the release agent layer 20 of this embodiment has good stability below 150°C, without decomposition and detachment, and still has...

Embodiment 3

[0039] With the polybutadiene polyurethane of 100 weight parts, the polyacrylate resin of 65 weight parts, the hydroxypropyl methacrylate of 15 weight parts, the trifluoroethyl methacrylate reactive monomer diluent of 40 weight parts, 40 weight parts Parts of octadecyl methacrylate active monomer diluent are uniformly mixed, and the initiator of 3 parts by weight is added as 2-hydroxyl-2-methyl-1-phenyl-1-acetone, and magnetically stirred for 120 seconds to obtain Release agent.

[0040] The release agent is evenly coated on the surface of the PET release film substrate 10 with a thickness of 45 μm, vacuum defoaming for 1 hour, N 2 Under certain conditions, it was irradiated with ultraviolet light and cured for 180 seconds to form a release agent layer 20 , and the thickness of the release agent layer 20 was measured to be 8 μm.

[0041] After testing, the release agent layer 20 of this embodiment has good stability below 150°C, without decomposition and detachment, and still...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com