A method for assembling a steel box girder of a curve bridge by a sliding method

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low safety, broken traction cables, unfavorable curve bridge construction, etc., and achieve strong applicability and outstanding effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

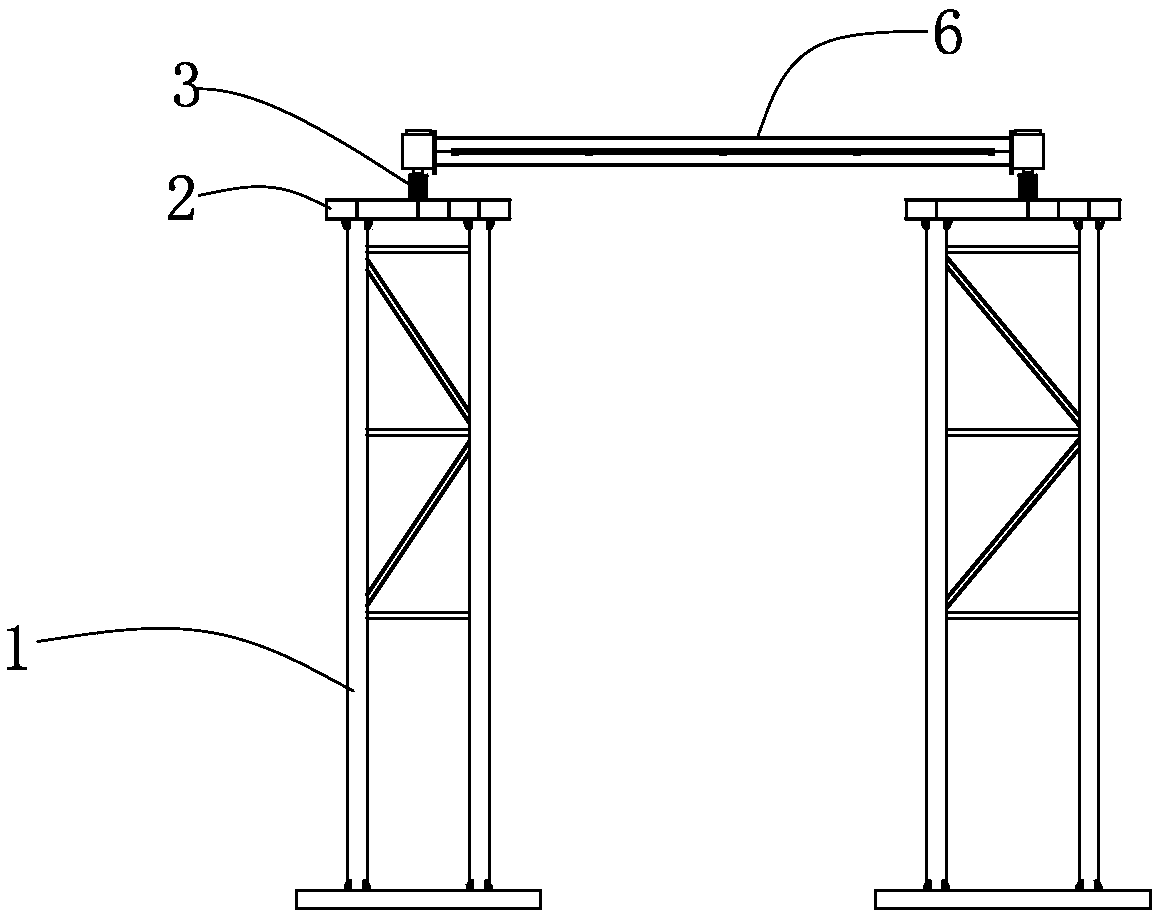

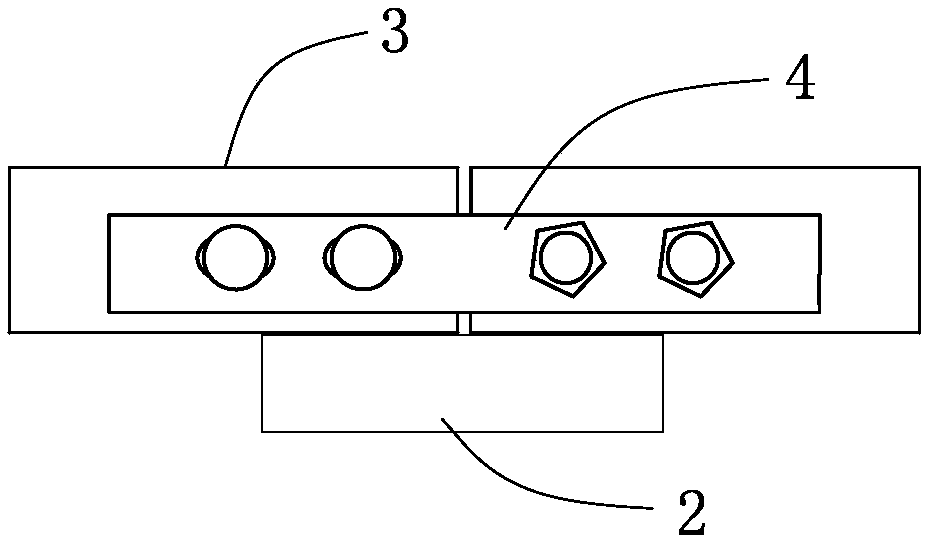

[0026] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

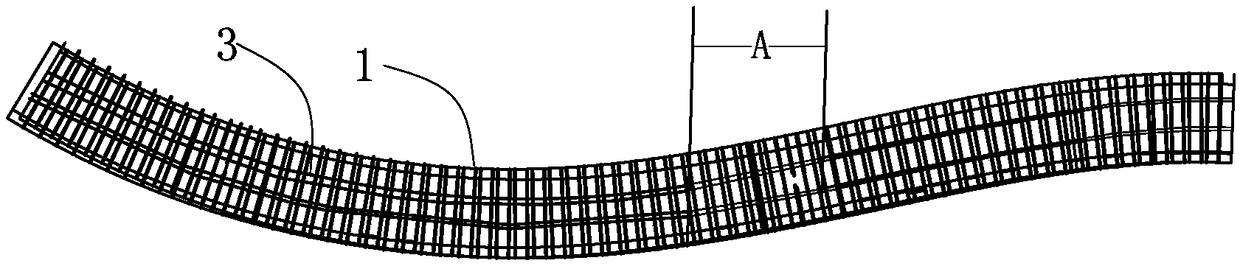

[0027] A bridge constructed by the applicant is located in the urban area, the bridge spans the subway, the on-site passenger flow is dense, and the bridge line is S-shaped. Since the ground load above the subway station is required not to exceed 20KN / ㎡, and the steel box girder of this bridge is 6000mm long, 29500mm wide, and weighs more than 20 tons per linear meter, if the hoisting method is used, the hoisting construction will be carried out at the top of the subway station. The concentrated ground load will far exceed the specified limit, so the hoisting method cannot be used for construction, and the slip method should be considered. However, the safety of the traditional sliding method is low, and the passenger flow is dense near the subway station. Considering the safety, the traditional sliding method should not be adopted, and the bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com