A prefabricated staggered joint assembled segmental split column for underground structures

An underground structure and split technology, which is applied to underwater structures, infrastructure engineering, buildings, etc., can solve problems such as insufficient horizontal deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

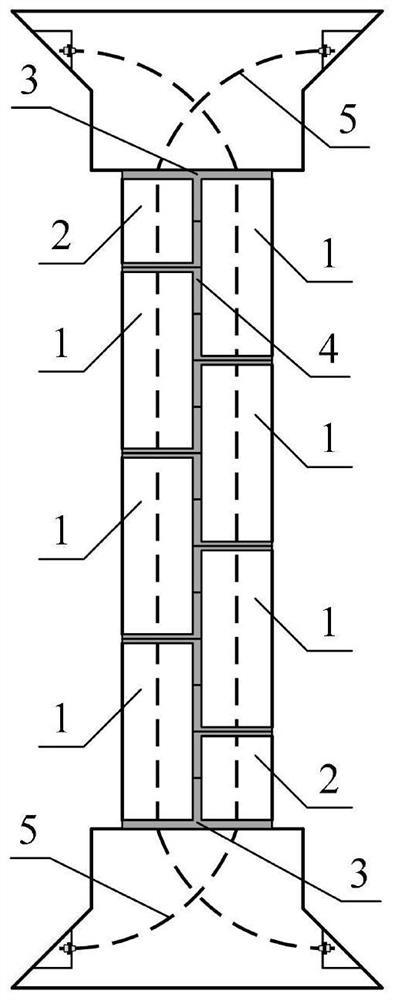

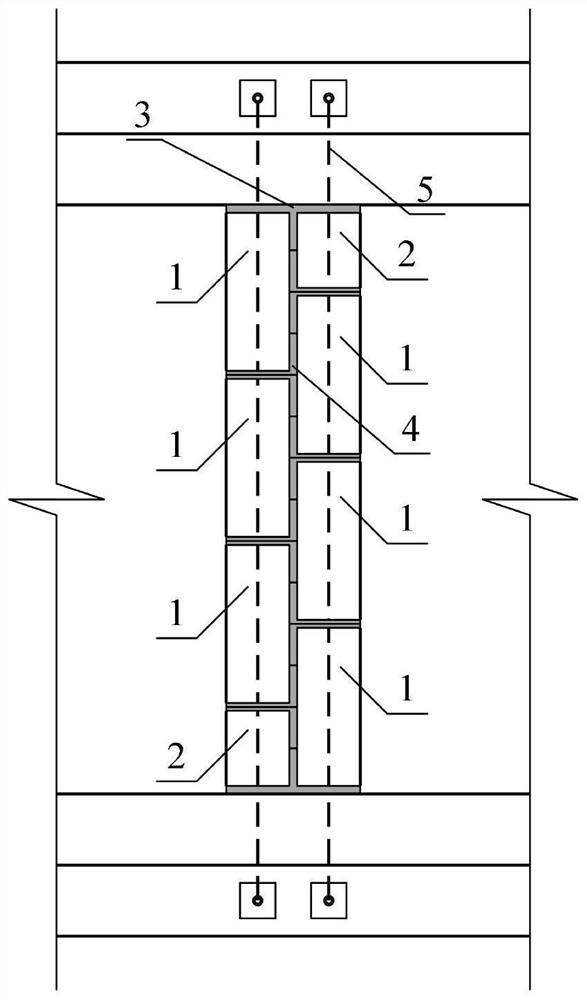

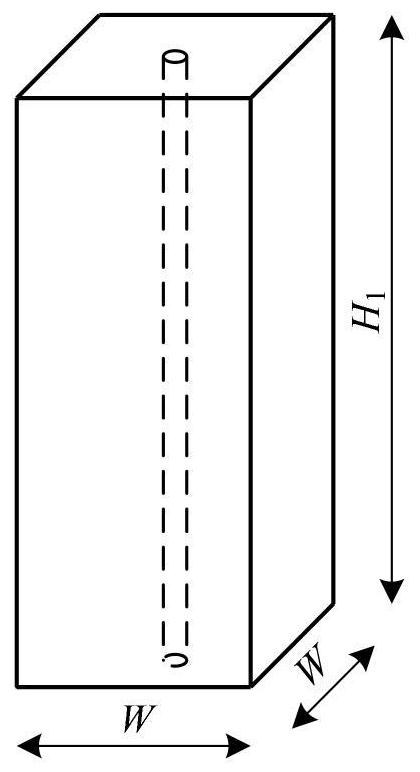

[0027] Such as Figure 1-13 As shown in Fig. 1, a prefabricated staggered segmental split column for underground structures, the split column consists of long segment prefabricated reinforced concrete columns (1), short segment prefabricated reinforced concrete columns (2), and rubber pads at the end of the columns layer (3), inter-column rubber cushion (4) and prestressed steel strands (5); the long section prefabricated reinforced concrete columns (1) are stacked in sequence along the height direction and a section of the short The segmental prefabricated reinforced concrete column (2) forms a split column unit; the four split column units are combined into a whole in two rows and two columns, and gaps are reserved between the split column units; the rubber cushion at the end of the column ( 3) It is arranged at the two ends of the split column unit, and is respectively connected with the top and bottom beams; the inter-column rubber cushion (4) is arranged in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com