Transient power control method for an engine that includes a compressor

An engine and compressor technology, used in engine control, machine/engine, combustion engine, etc., to solve problems such as the inability of electric drive compressors to deliver boost quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

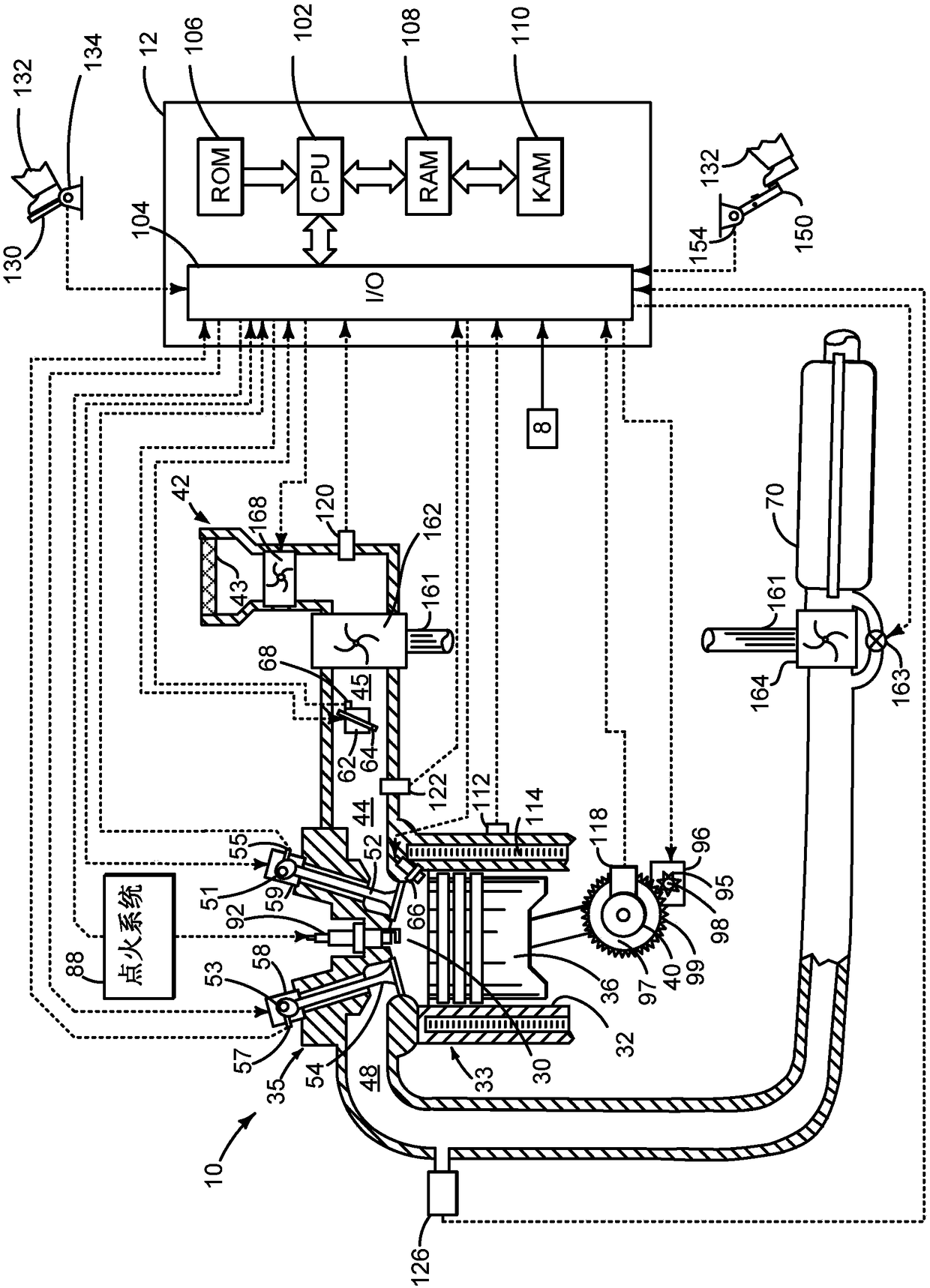

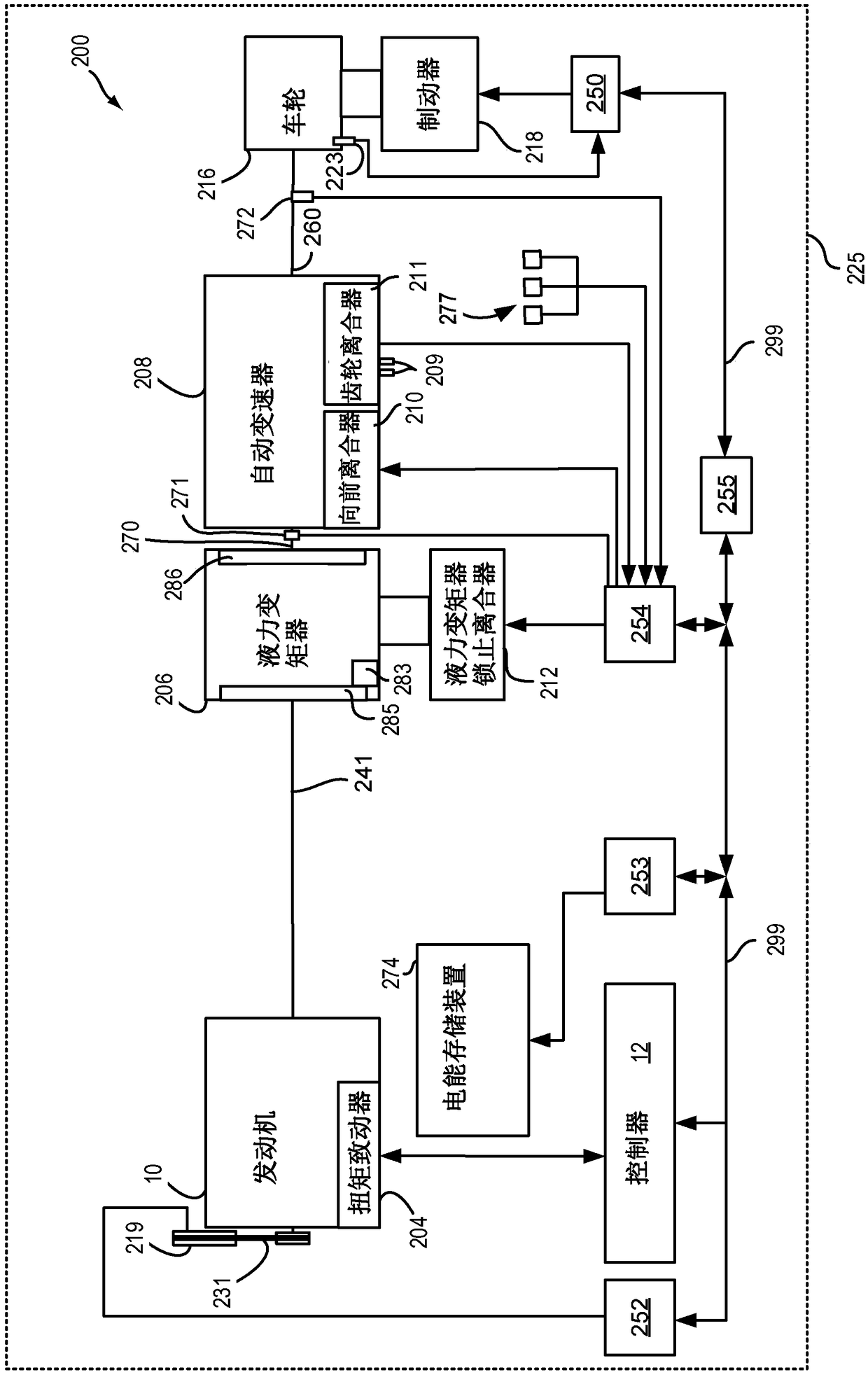

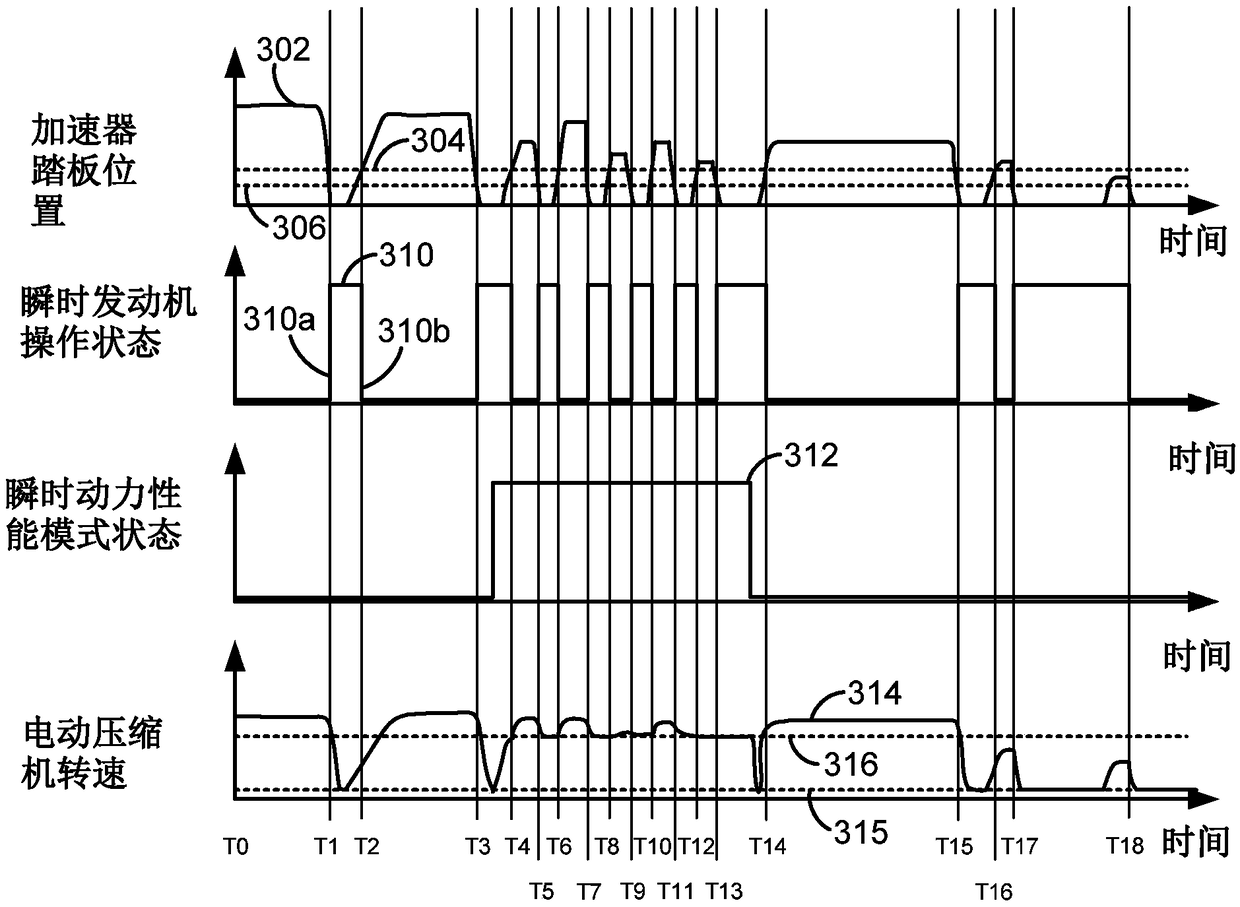

[0015] The invention relates to an electrically driven compressor controlling an engine and supplying air to the engine. Internal combustion engines can be figure 1 Configure as shown. like figure 2 As shown, the internal combustion engine may be included in a driveline or powertrain of a vehicle. The engine and electrically driven compressor can be based on image 3 and Figure 4 The sequence shown is performed. The internal combustion engine and the electrically driven compressor may be operated by a controller including means for performing Figure 5 and Image 6 The executable instructions for the method.

[0016] refer to figure 1 , including multiple cylinders ( figure 1 An internal combustion engine 10 of which one cylinder is shown) is controlled by an electronic engine controller 12 . Engine 10 is constructed of cylinder head 35 and cylinder block 33 including combustion chamber 30 and cylinder walls 32 . Piston 36 is positioned therein and reciprocates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com