Compressor blade and compressor

A compressor and blade technology, applied in the field of gas turbines, can solve problems such as increasing friction loss and increasing blade surface area, and achieve the effects of reducing friction loss, reducing airflow separation, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

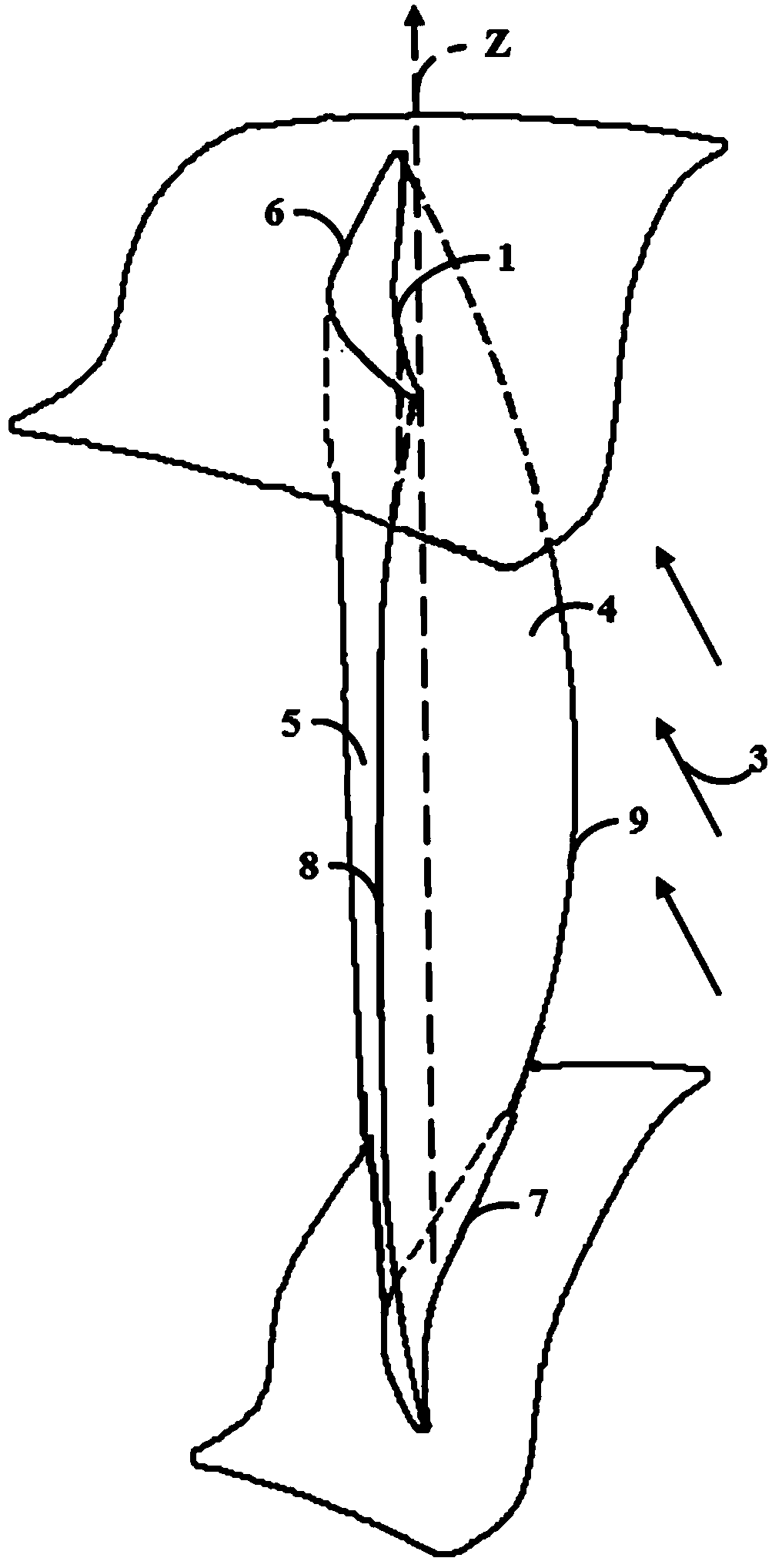

[0026] combine figure 1 and figure 2 As shown, the embodiment of the present invention provides a compressor blade. The compressor blade has a suction side 5 and a pressure side 4. The blade includes a blade root 6, a blade tip 7, and radial extended leaves;

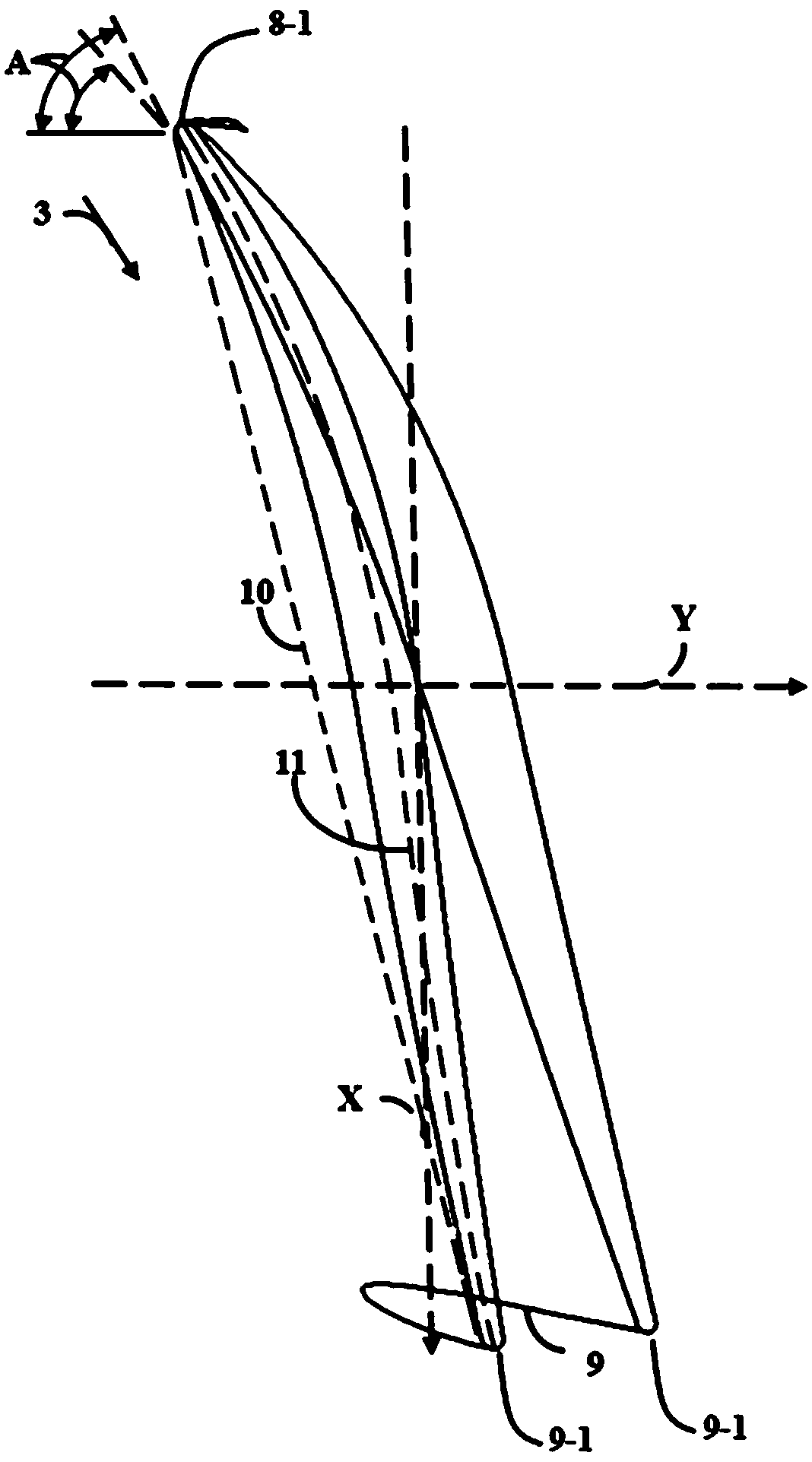

[0027] The cross-sections of the blade top 7, blade center and blade root 6 are all parallel to the XY plane, wherein the X direction represents the axial direction, the Y direction represents the tangential direction, and the Z direction represents the radial direction; the trailing edge 9 of the blade root 6 and the trailing edge 9 of the blade tip 7 are twisted towards the suction side 5 respectively, and the trailing edge 9 of the blade is twisted towards the pressure side 4, so that the trailing edge point 9-1 on the cross-section of the blade tip 7 revolves around its leading edge point 8- 1 Rotate a specified angle along the direction where the suction side 5 is located, so that the trailing edge point 9-1 on t...

Embodiment 2

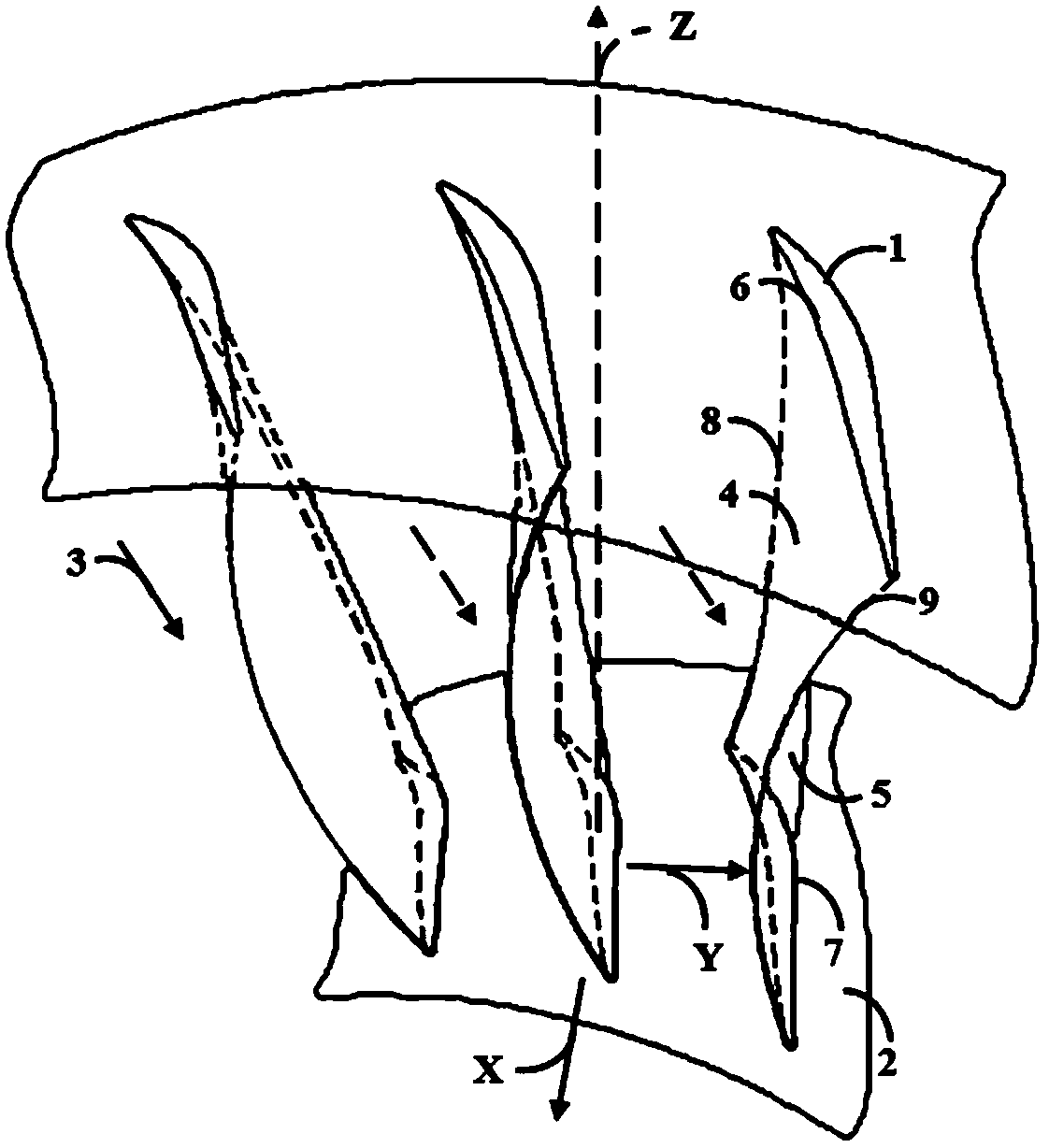

[0034] Such as image 3 As shown, the present invention also provides a compressor, which includes a hub 2 and a plurality of compressor blades 1 described above, and the plurality of compressor blades 1 are sequentially arranged at intervals along the circumference of the hub 2 . Since every two adjacent compressor blades 1 can surround and form an air 3 flow channel, when the compressor is running, the air 3 will be gradually compressed when it flows through the air 3 flow channel.

[0035] Preferably, the compressor blade 1 and the hub 2 are integrally formed. When manufacturing, it can be processed by milling, electrochemical and other methods. It should be noted that the compressor blade 1 can be integrally formed with the hub 2, and can also be detachably connected with the hub 2. For example, a dovetail can be arranged on the tip 7 of the compressor blade 1, and a dovetail can be provided on the side wall of the hub 2. Dovetails correspond one-to-one to dovetail slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com