Magnetic gas double-suspension breaking-type cone bearing with porous media

A technology of porous media and tapered bearings, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of wide temperature range, low load capacity, small torque, etc., achieve high circumferential speed, long life, and reduce assembly effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

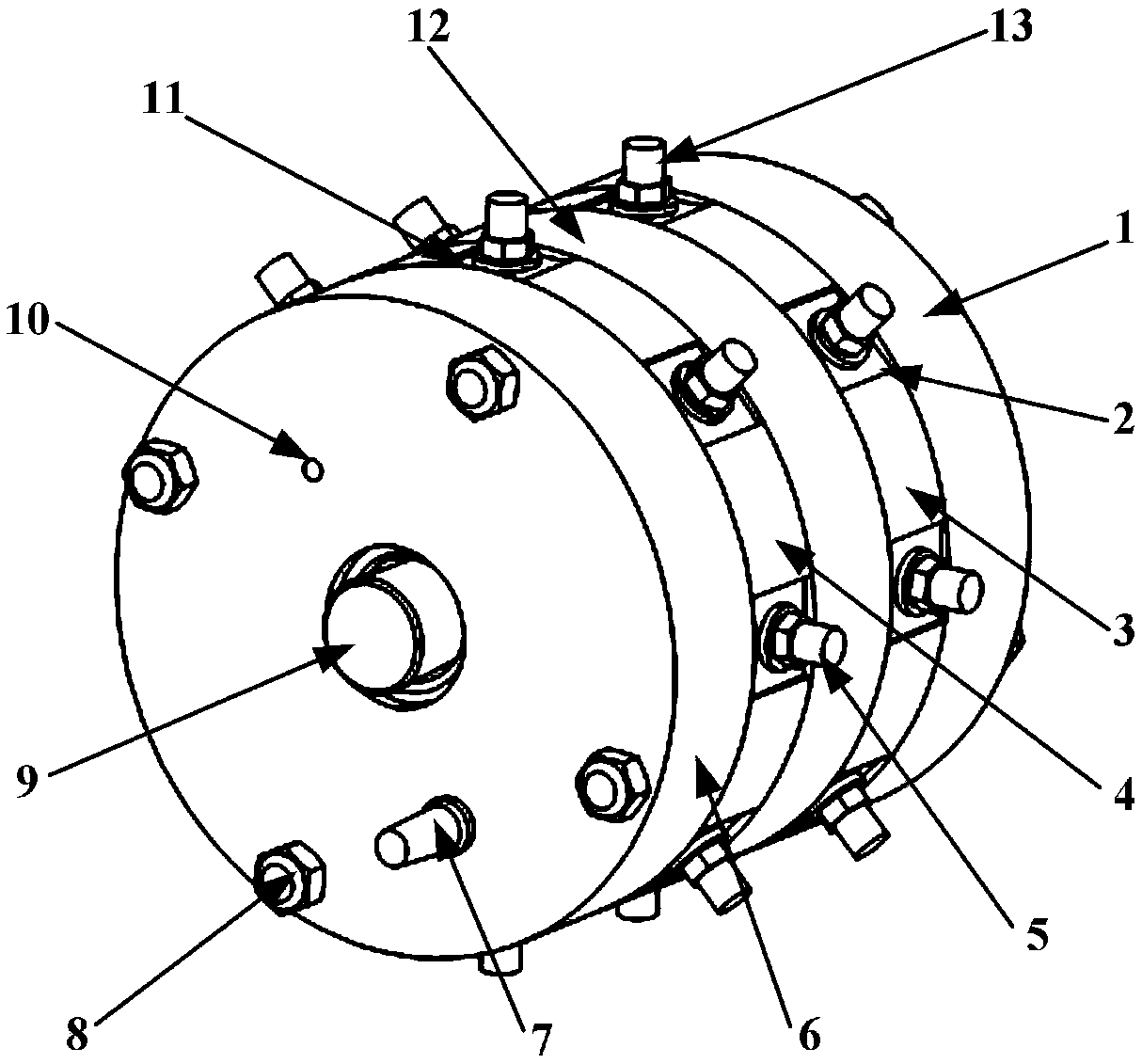

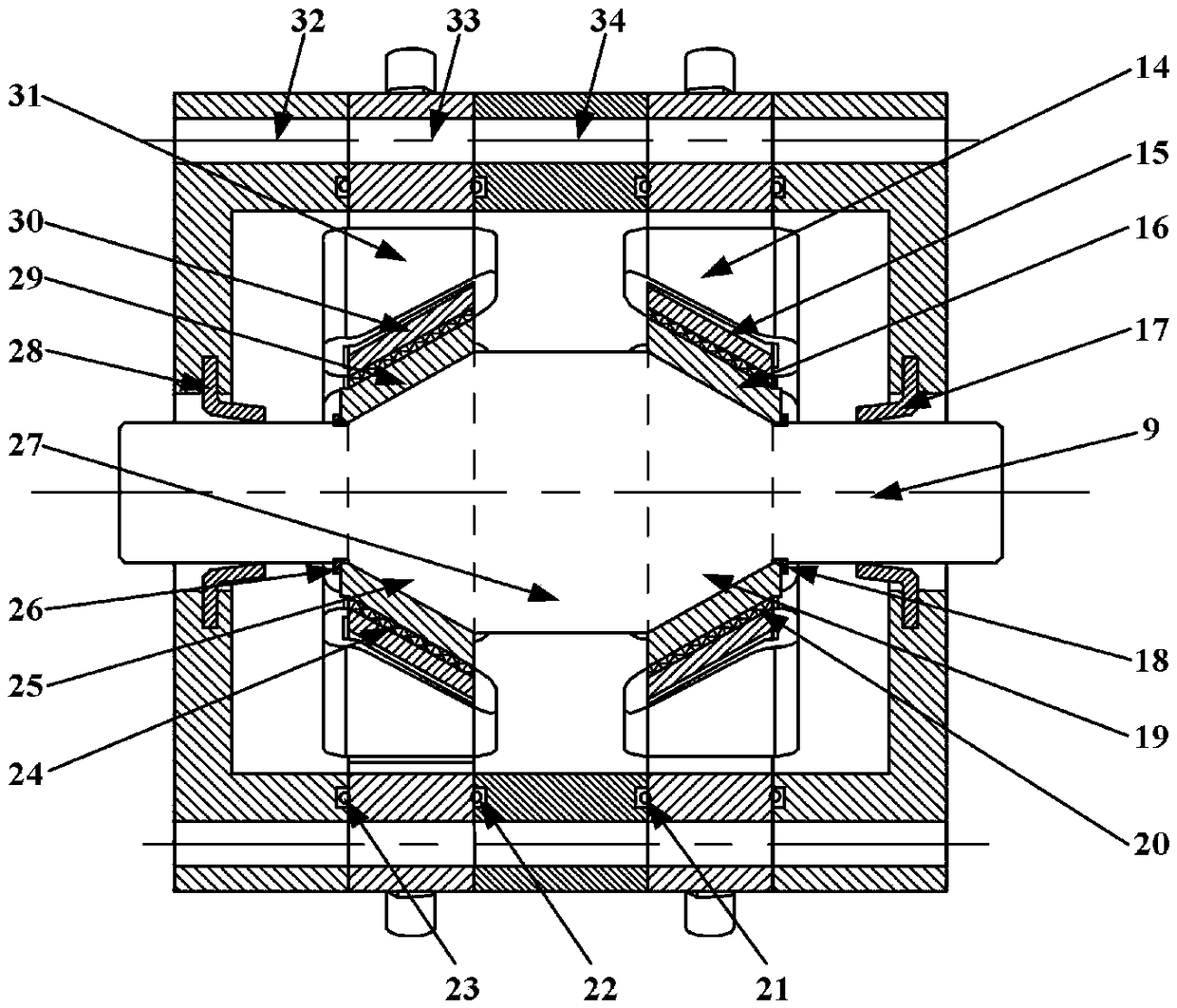

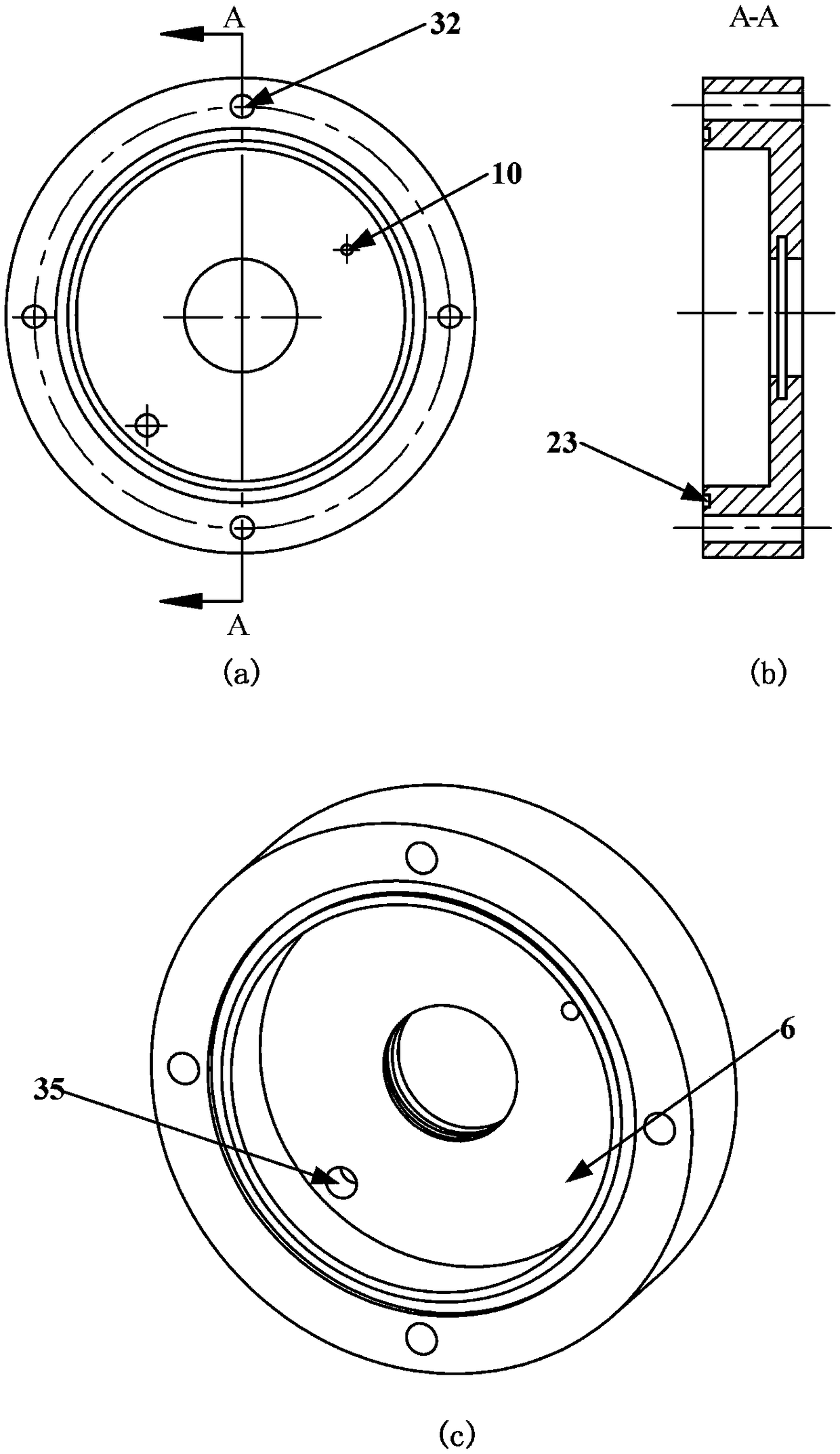

[0025] The present invention is described in detail below in conjunction with accompanying drawing: As a kind of preferred scheme, the diameter of the small cylinder section of rotor shaft 9 is 25mm, and the diameter of large cylinder section is 50mm, and length is 30mm, the first cone structure on the rotor shaft 9 Section 25 and the second cone structure section 19 have a taper of 30° and a length of 21.5 mm. The diameters of the first and second stators 4 and 3 are 142 mm and a thickness of 22 mm. Eight of the first stators 4 Air intake hole 36 diameters are 5mm, and the long side of air intake chamber projection is 16mm, and short side is 11mm, and height is 22mm, and width is 2mm, and through hole 33 diameters are 8mm, and cutting platform 11 is deep 2mm; The outer diameter of the large end of the magnetic sleeve 29,16 is 62mm, the inner diameter of the large end is 50mm, the taper is 30°, and the projected length is 23mm; the outer diameter of the first and second bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com