Hydraulic hydromechanical composite multi-power flow transmission device

A hydraulic, multi-power technology, applied in fluid transmission, transmission, mechanical equipment, etc., can solve the problem of inability to achieve stepless change of gear transition radius, affecting vehicle acceleration performance, and difficulty in realizing stepless adjustment of fan speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

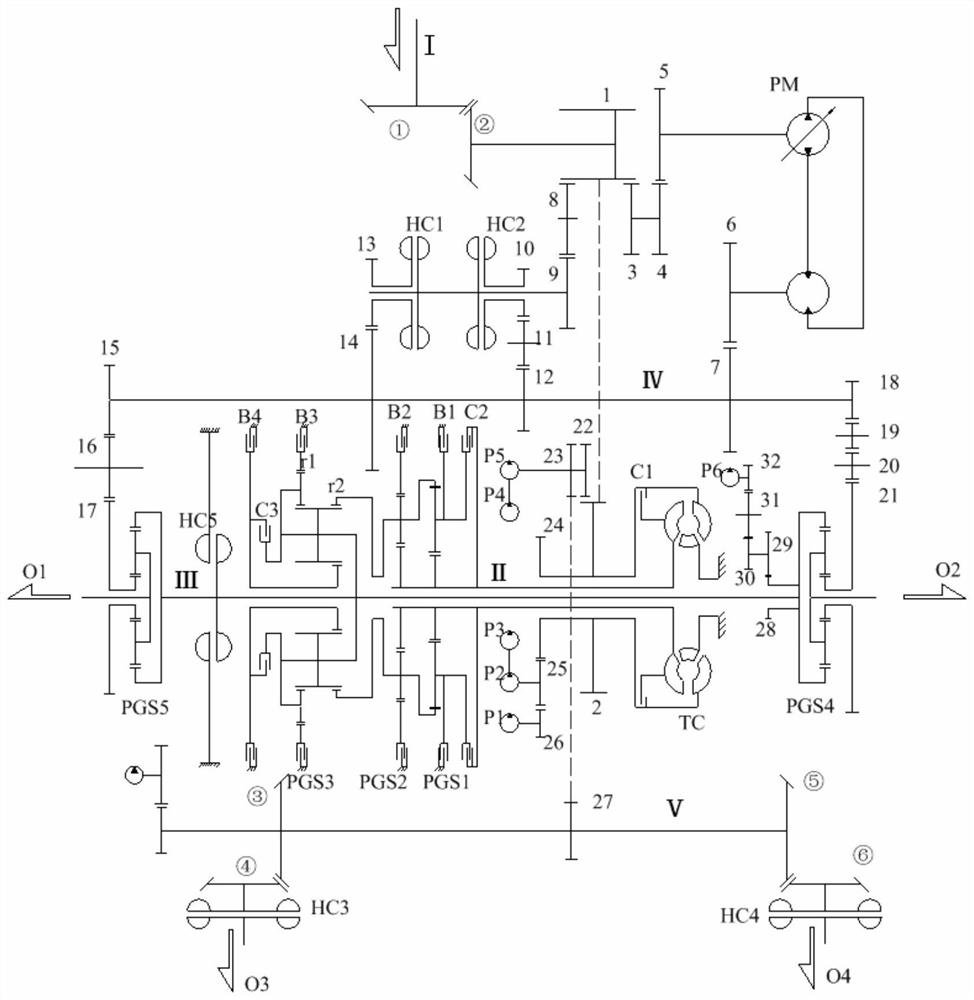

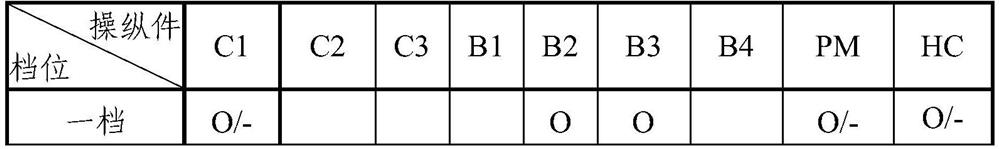

[0192] This example figure 1 As shown, the transmission device provided is suitable for large-tonnage crawler vehicles with longitudinal engine arrangement, rear powertrain and rear drive, in which the planetary row, hydraulic pressure and hydraulic components are arranged in sequence and connected with each other by transmission components. The input shaft is connected to the first spiral bevel gear ①, which is generally an elastic coupling connected to the output end of the engine, and is used to input the power of the engine to the transmission device. There are four output terminals, which are respectively connected to the first output terminal O1, the second output terminal O2, the third output terminal O3, and the fourth output terminal O4, wherein the first output shaft O1 and the second output shaft O2 are connected to the vehicle side reducer , to output the power to the driving wheel; the second output terminal O2 and the third output terminal O3 are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com