Overflow cut-off valve

A shut-off valve, over-current technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve the problems of gas overflow poisoning or explosion, life safety threat, family property loss, etc., to ensure gas safety and small size , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

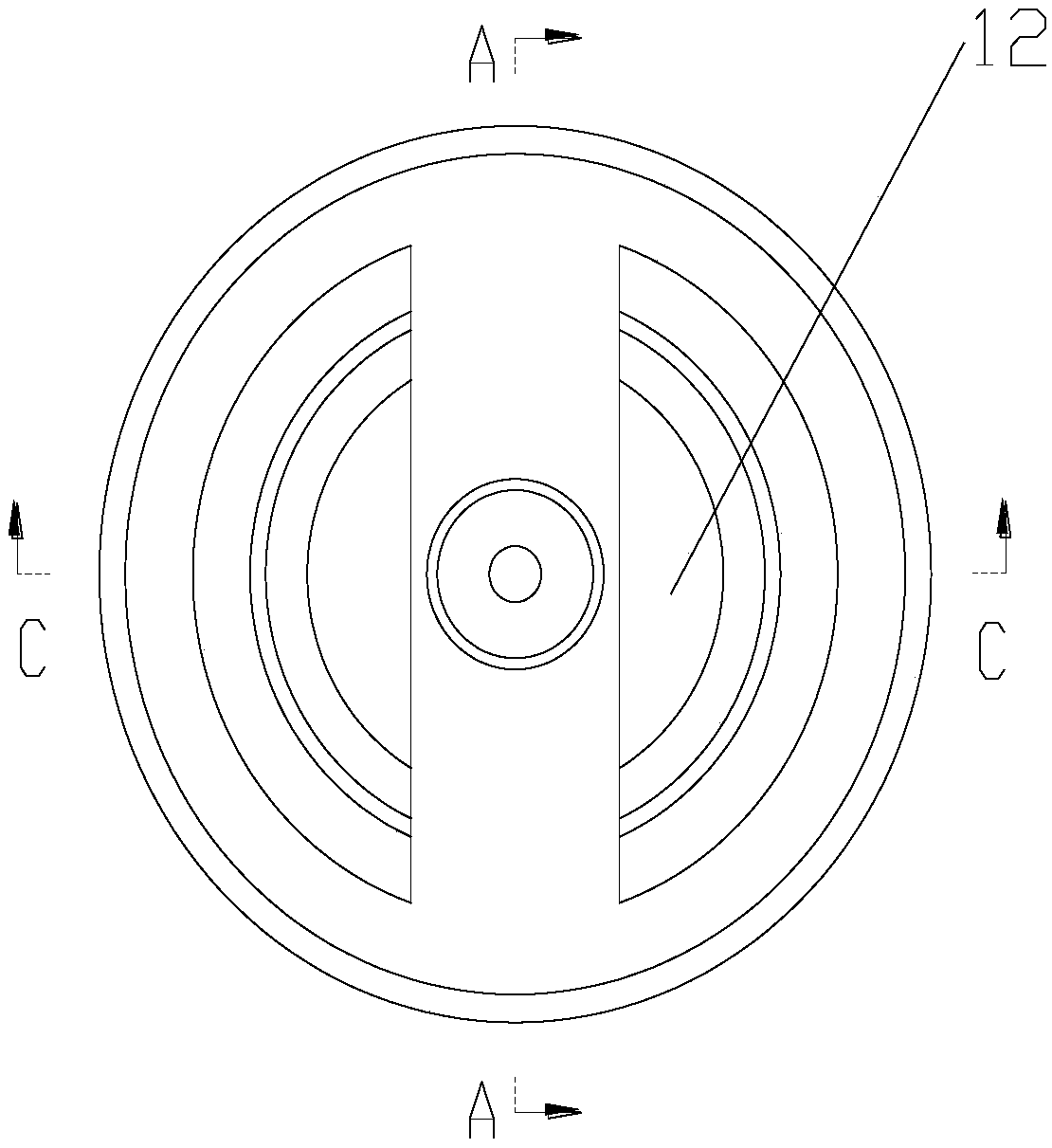

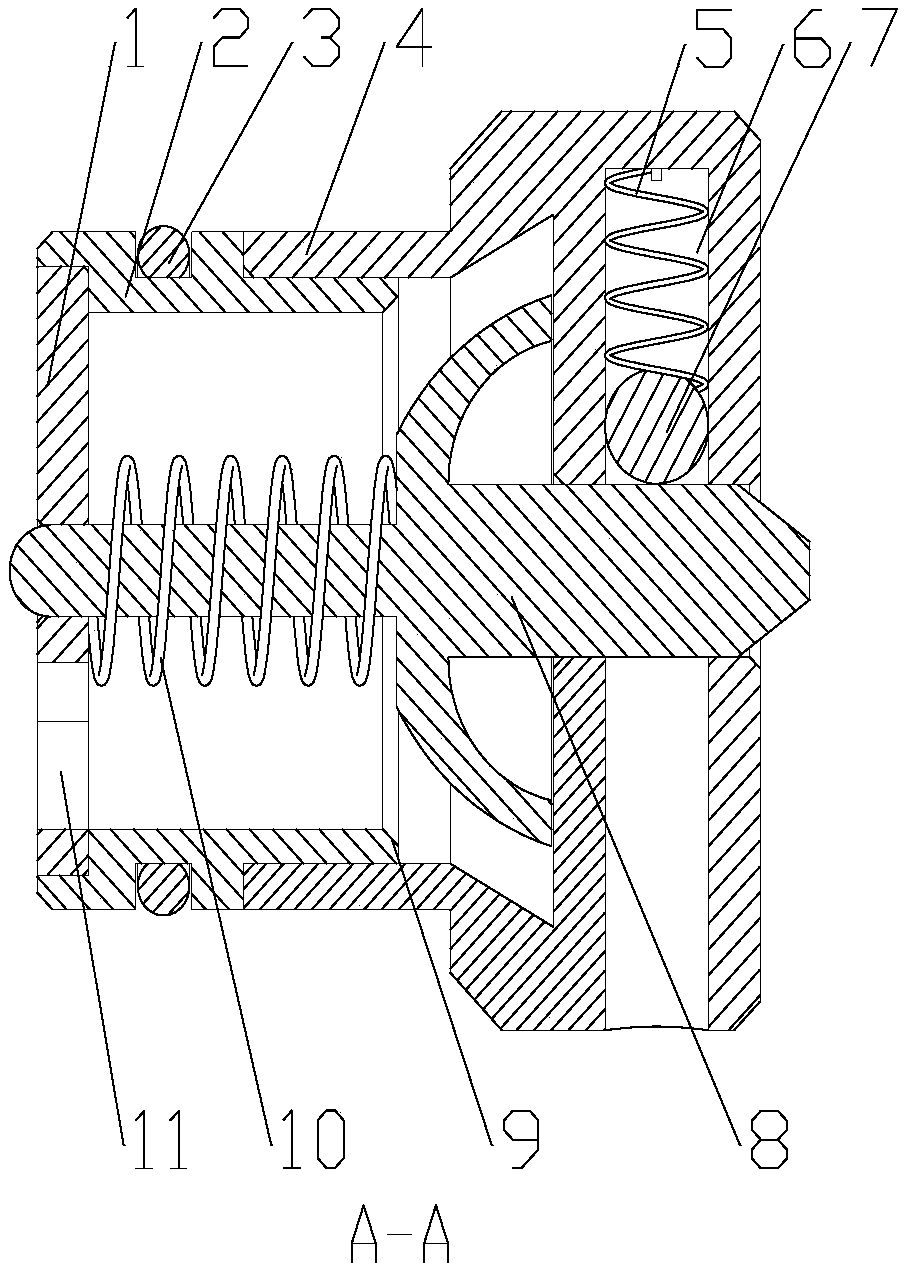

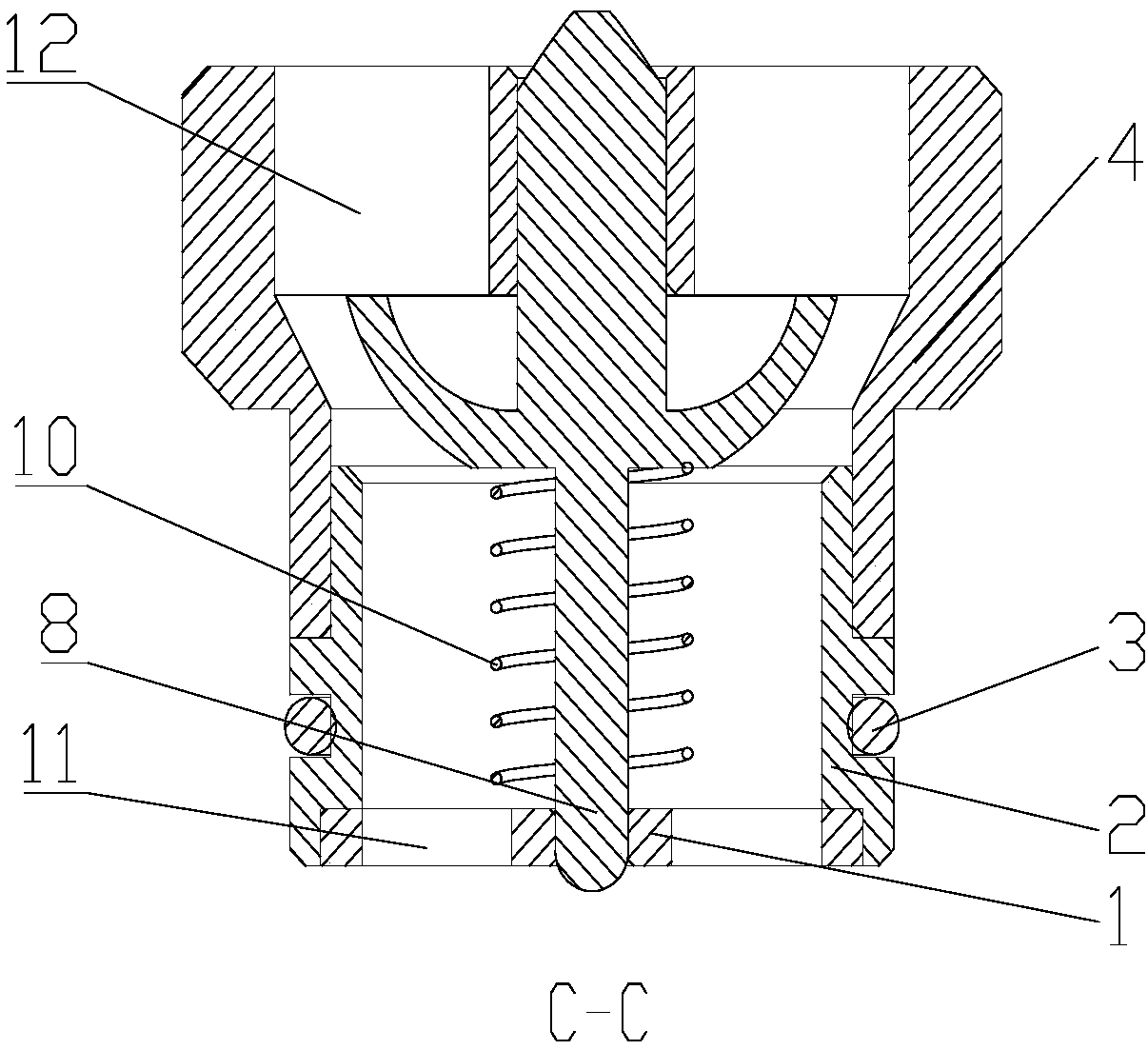

[0027] Such as figure 2 , image 3 and Figure 5 The overcurrent cut-off valve shown includes a valve body and a cut-off assembly, the cut-off assembly is installed in the valve body, and the valve body includes an air inlet flange 4 through which gas enters, and a retainer installed with an interference fit with the air inlet flange 4 Frame 2, an air outlet support frame 1 installed with an interference fit with the cage 2, the cut-off assembly includes a release spring 5, a steel ball 7, a valve core 8 and a return spring 10 that resets the valve core 8 after cutting off the gas, as Figure 6 As shown, the valve core 8 includes an upper guiding plug 81, a valve disc 83 and a lower guiding plug 82 connected in sequence. The valve core 8 has an integrated structure, and the structure is firmer and will not break. The valve disc The shape of 83 is hemispherical, and the opening faces the direction of the air inlet flange 4. The return spring 10 is sleeved on the guide lower ...

Embodiment 2

[0032] The working principle of this embodiment is the same as that of Embodiment 1, the difference is that: the valve disc 83 of the valve core 8 is in the shape of a sheet, the retainer 2 is threadedly connected with the air inlet flange 4, and the air outlet support frame 1 is connected with the retainer. Frame 2 threaded connection.

Embodiment 3

[0034] The working principle of this embodiment is the same as that of Embodiment 1, the difference is that: the retainer 2 and the air outlet support frame 1 adopt an integrated structure, and are connected to the air inlet flange 4 through threaded connection or interference fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com