Air conditioner device with double cold source heat pipes

An air-conditioning device and dual-cooling source technology, which is applied in air-conditioning systems, refrigerators, household heating, etc., can solve the problems of uneven distribution of compressor refrigeration oil, system failure, and failure to achieve backup, etc., and achieve good energy-saving effects , Improving refrigeration efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

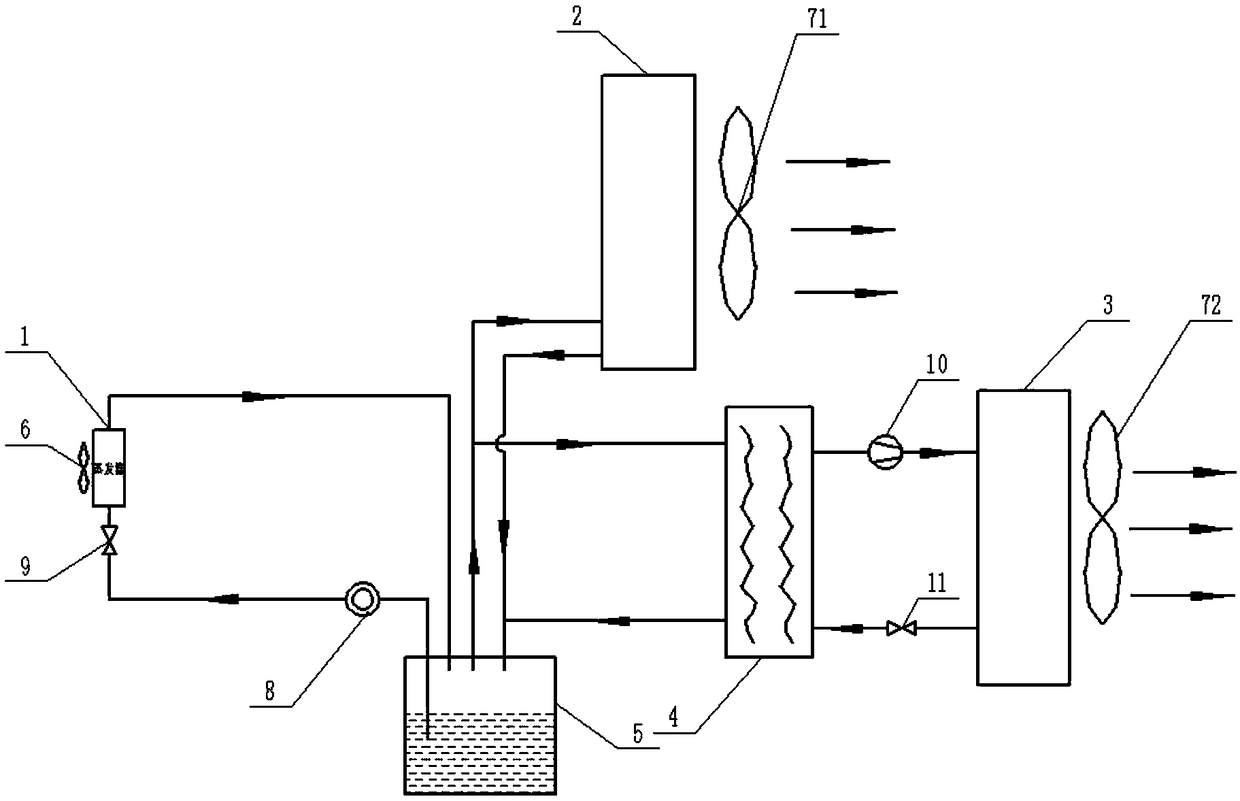

[0023] Please refer to figure 1 The shown dual cold source heat pipe air conditioner of the present invention includes a heat pipe end system, a liquid storage tank 5, a circulation pump 8, a cold source system, a temperature sensor and a control module. The inlet of the circulating pump 8 communicates with the liquid storage tank 5, and the inlet goes deep into the bottom of the liquid storage tank 5; Communication; the inlet and outlet of the cold source system communicate with the liquid storage tank 5 respectively, wherein the inlet of the cold source system is located at the top of the liquid storage tank 5 .

[0024] The heat pipe end system comprises a heat pipe evaporator 1, an evaporator fan 6 and a second electronic expansion valve 9, and the second electronic expansion valve 9 is connected between the inlet of the heat pipe evaporator 1 and the outlet of the circulation pump 8; the evaporator fan 6 Installed on one side of the heat pipe evaporator 1 to promote heat...

specific Embodiment approach 2

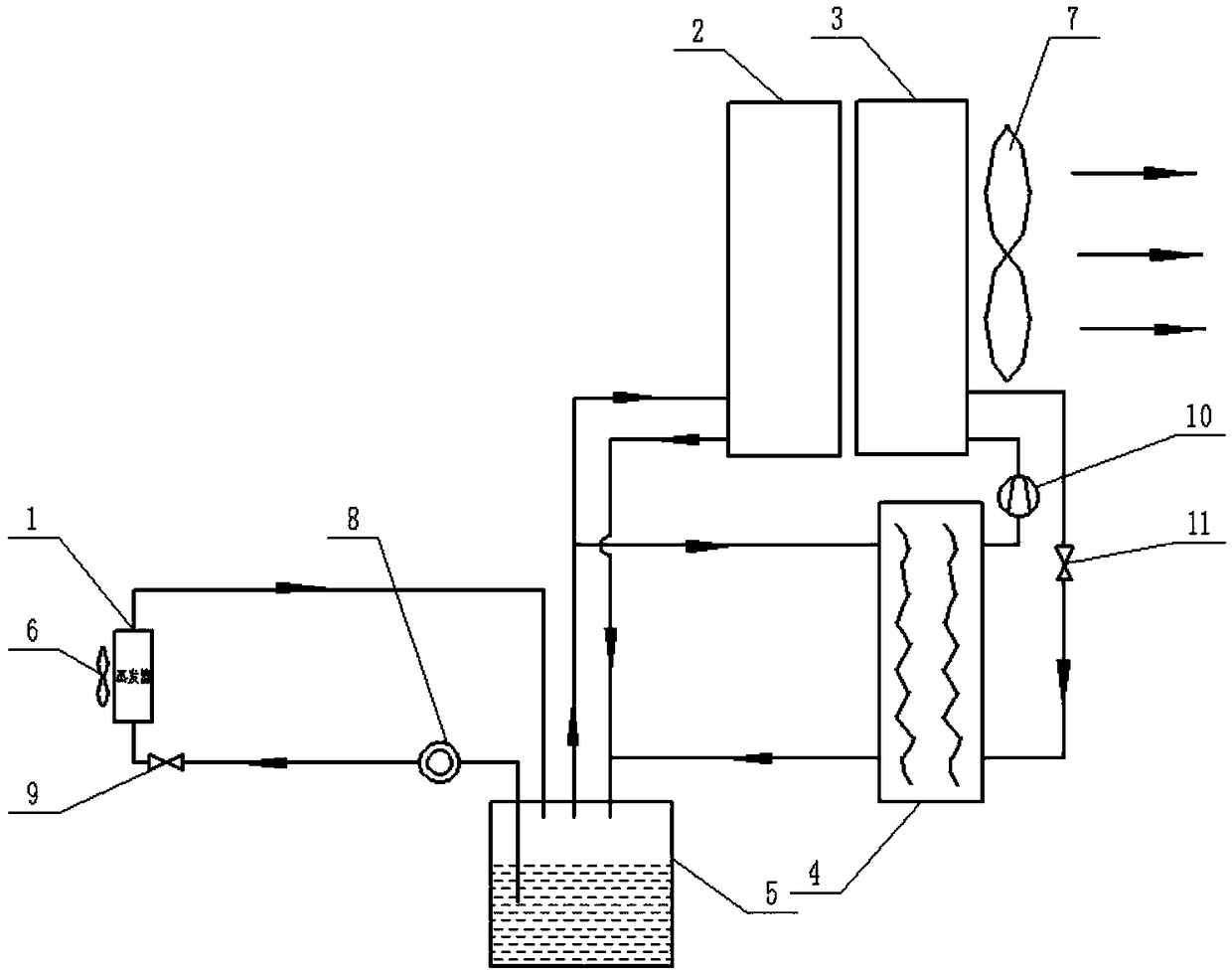

[0040] Please refer to figure 2 As shown, in this embodiment, the heat pipe condenser 2 of the natural cold source and the compressor condenser 3 of the compressor cold source system share a condenser fan 7, and the compressor condenser 3 and the heat pipe condenser 2 are placed side by side. The condenser fan 7 is installed on one side of the compressor condenser 3, and the wind direction is from the heat pipe condenser 2 to the compressor condenser 3, so that the outdoor air passes through the heat pipe condenser 2 and the compressor condenser 3 to exchange heat with it. All the other parts are the same as the first embodiment, and the working method is also the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com