Measurement system for front and back edge positions of engine guide vane

A guide vane and measurement system technology, applied in the direction of mechanical measuring devices, measuring devices, mechanical devices, etc., can solve the problems of low detection efficiency, many dial indicators, limited detection range, etc., and achieve convenient operation, simple structure, The effect of full cross-section inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

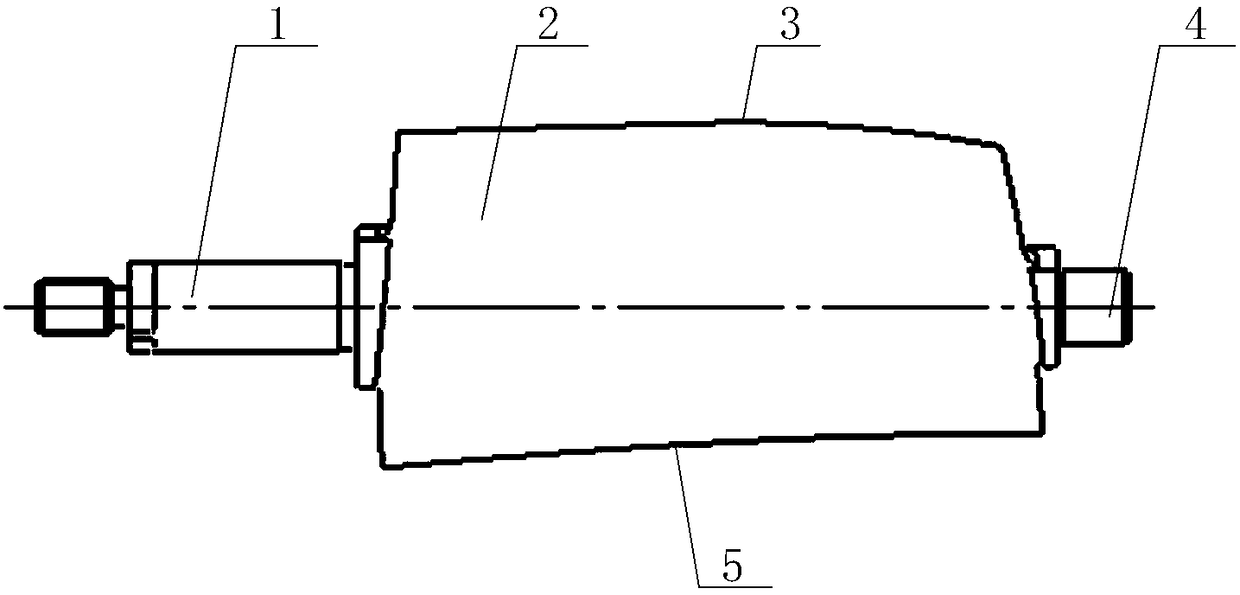

[0036] see figure 1 , the guide vane includes upper journal 1, airfoil 2, trailing edge 3, lower journal 4 and leading edge 5; upper journal 1 is connected to one end of blade airfoil 2, and the other end of blade airfoil 2 is connected to lower journal 4 ; One side of the blade body 2 is the trailing edge 3 , and the other side is the leading edge 5 . The present invention measures the position of the front and rear edges of the guide vane, that is, measures the distance from the front or rear edge of a certain section of the guide vane to the central axis of the guide vane.

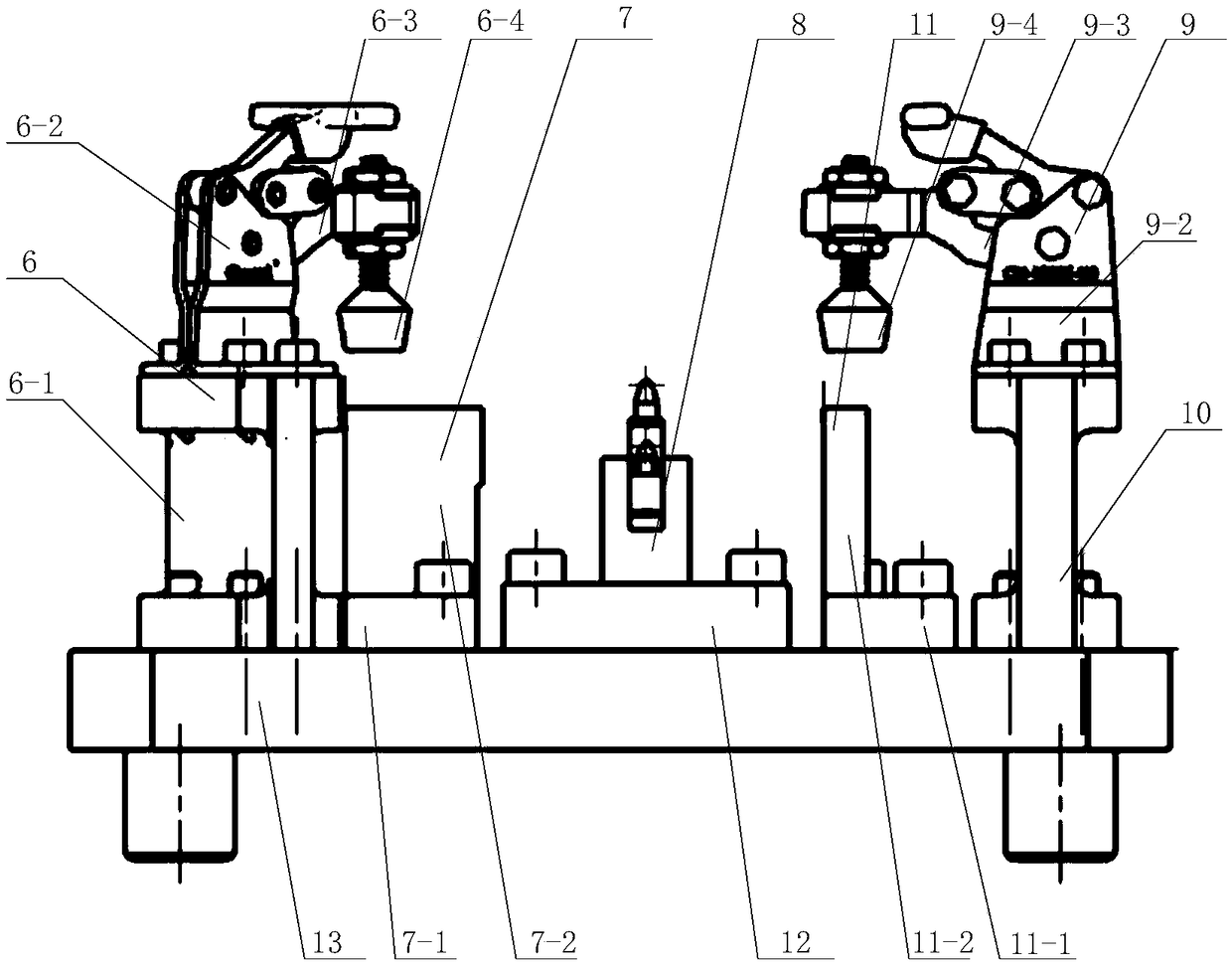

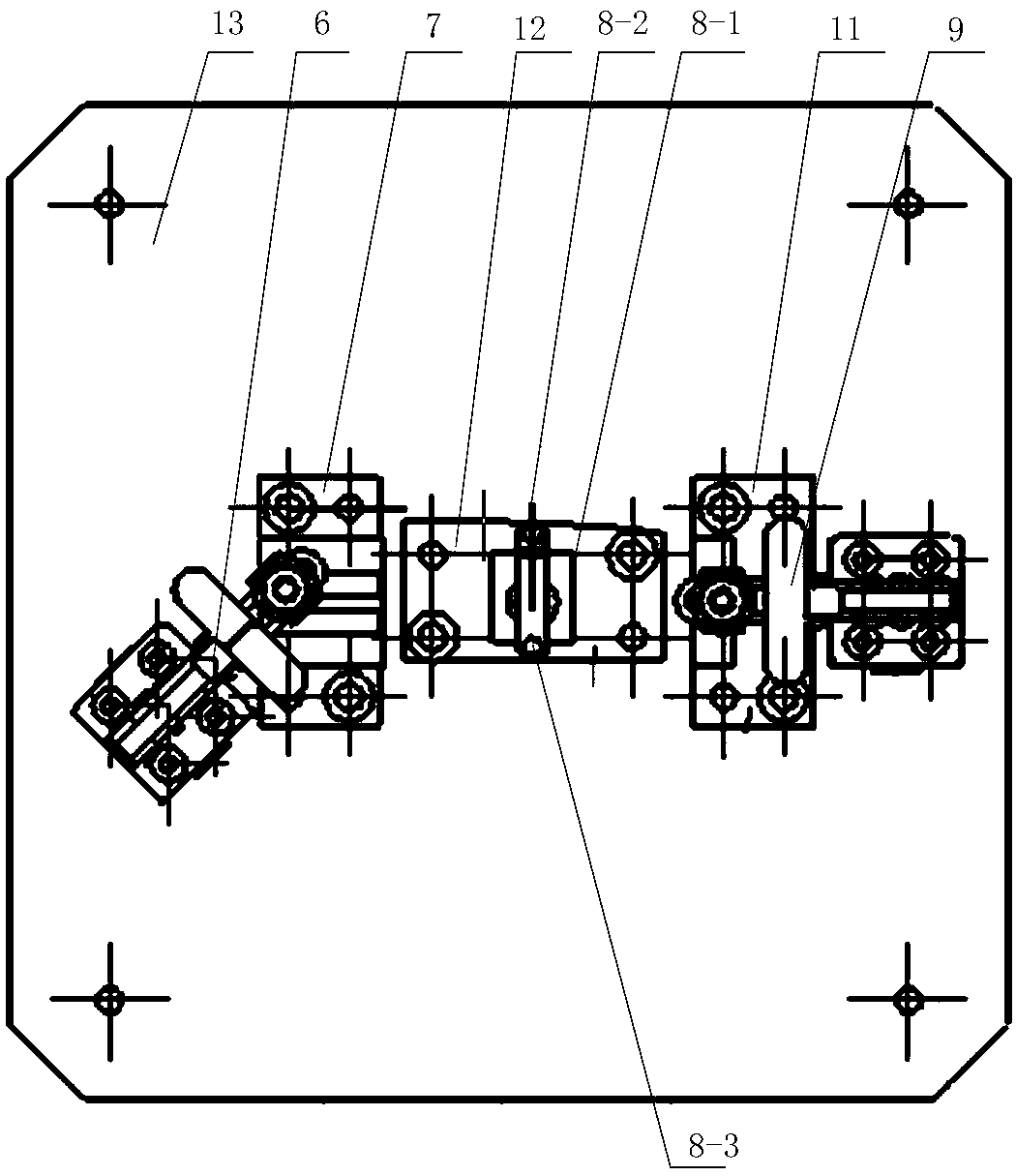

[0037] The position measurement system of the front and rear edges of the guide vane includes a clamping device and a measuring device;

[0038] see figure 2 , The clamping device includes a first pressing mechanism 6 , a first positioning mechanism 7 , an airfoil positioning mechanism 8 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com