Heat power plant heating network monitoring system

A technology of monitoring system and thermal power plant, applied in the field of power system, can solve the problems of the stability and reliability of the automatic control system and the weak and lack of anti-interference design, and can not effectively solve the problems of hydraulic balance and thermal balance of the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

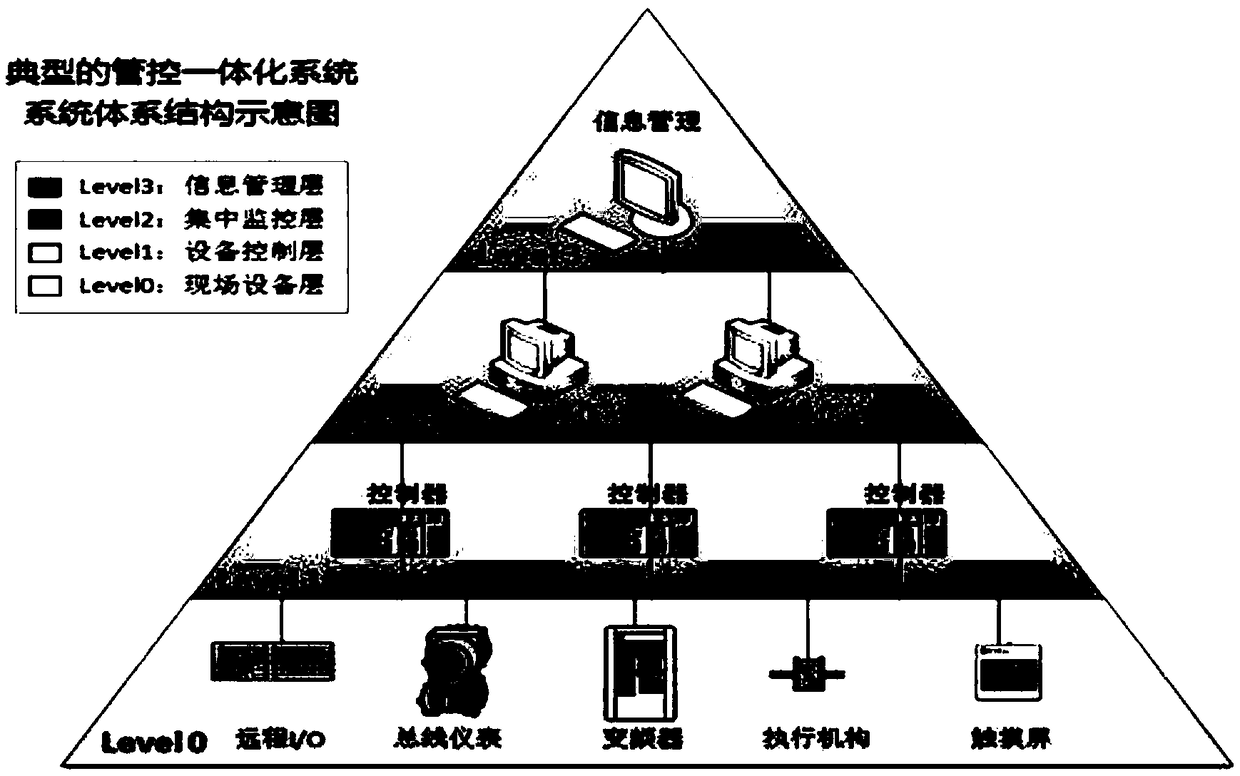

[0028] The system such as figure 1 As shown, it consists of field device layer, centralized monitoring layer, information management layer and network connecting each layer.

[0029] 1. Field device layer

[0030] The field equipment layer is composed of measuring instruments, actuators, remote I / O, PLC and other control systems, control network and liquid crystal display operation terminals arranged on site. The liquid crystal display mainly completes the display of various monitoring screens and acquisition parameters, and realizes the input of some parameter setting information. The main functions of the field equipment layer: First, realize the integration of the control systems of each thermal station, including the operation status of the equipment (such as the operation status of the water pump, valve position, etc.), the operating parameters of the thermal stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com