A method for compiling a test load spectrum

A technology of load spectrum and load, which is applied in the field of test load spectrum compilation, can solve the problems that the real loading conditions of key components cannot be reproduced, the load change process is not considered, and the cost of research and development is increased, so as to shorten the test period, reduce the test cost, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

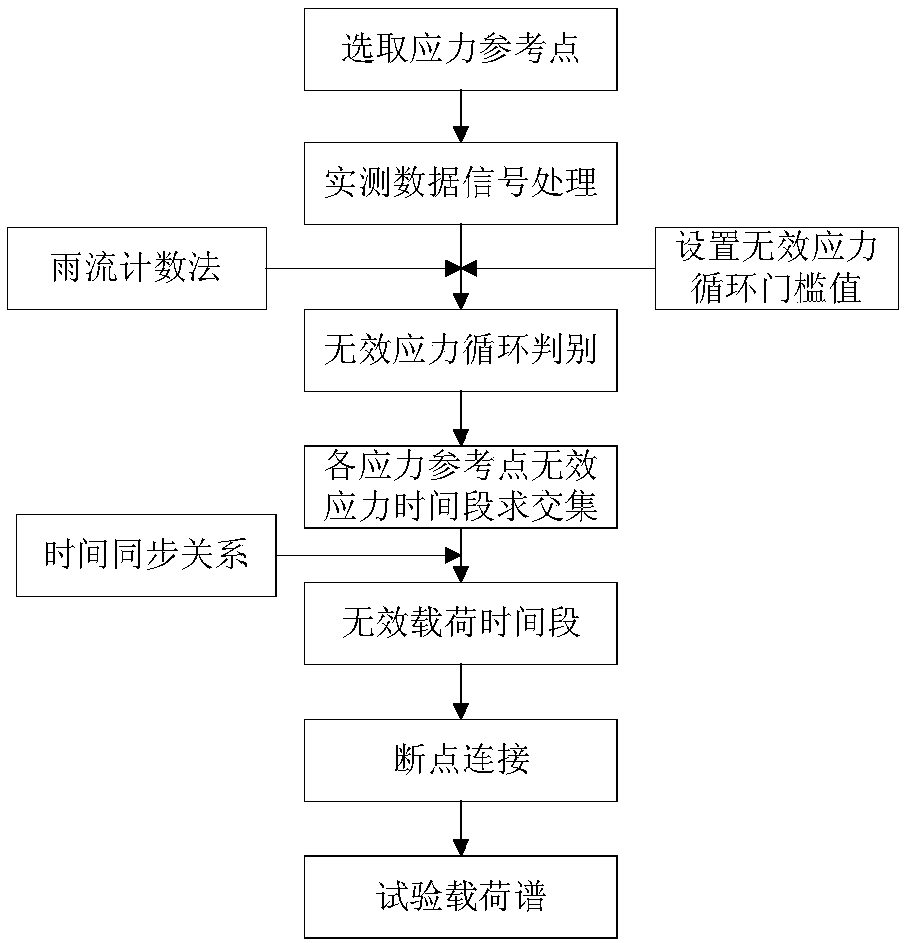

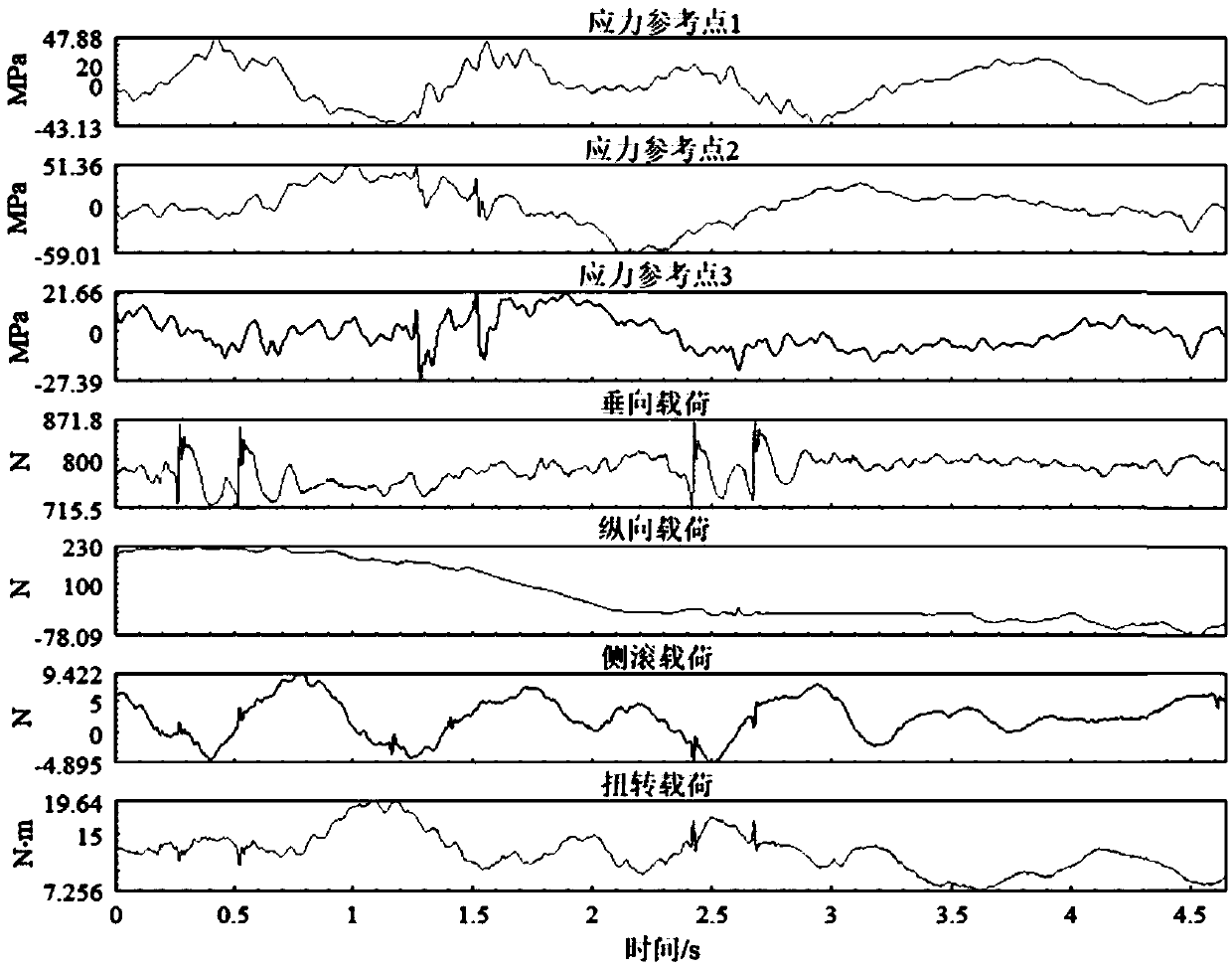

[0058] Such as figure 1 As shown, a method for compiling the load spectrum of the simulated line loading test for key components of railway vehicles includes the following steps:

[0059] Step 1. Selection of stress reference points

[0060]Using the simulation calculation method, combined with the actual use of key components, select the fatigue risk parts, and then select the points with relatively large stress in the simulation calculation and the points that often have problems in actual use as stress reference points. Table 1 shows the selection results of the stress reference point of a railway freight car body.

[0061] Table 1 Selection results of stress reference points for a certain railway freight car body

[0062] serial number

Location

1

The connection area between the lower cover plate of the outer pillow beam and the middle beam

2

The connection area between the lower cover plate of the pillow beam and the middle beam

3 ...

Embodiment 2

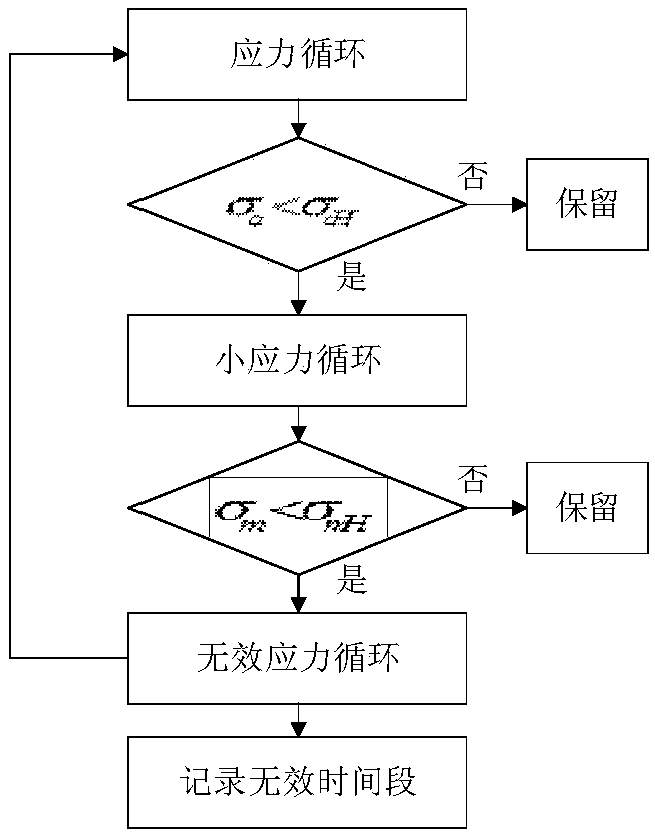

[0099] Except for special instructions, this embodiment adopts the same method as that of Embodiment 1. This embodiment compares the difference between the method of the present invention without introducing the stress average threshold value and only setting the stress amplitude threshold value.

[0100] The stress time history of the stress reference point 1 of a railway freight car body is obtained by the rainflow counting method to obtain two stress cycles 1 and 2, as shown in Figure 5 shown. The statistical results of stress cycle 1 and stress cycle 2 are shown in Table 5. The stress amplitudes of stress cycle 1 and stress cycle 2 are lower than the stress amplitude threshold σ aH , the average stress value is higher than the stress average value threshold σ mH According to the judgment of the existing technology, the two stress cycles belong to the invalid stress cycle, but this part of the stress cycle contributes to the damage of key components and belongs to the ef...

Embodiment 3

[0104] Except for special instructions, this embodiment adopts the same method as that of embodiment 1. In this embodiment, the difference in effect between straight line connection and semi-positive curve connection after deleting invalid and invalid load time periods is compared.

[0105] After deleting the invalid load period, the load time history has a breakpoint, such as Image 6 shown. The connection mode between two adjacent breakpoints is as follows: Figure 7 as shown, Figure 7 (a) is the traditional connection method. After the invalid time period is deleted, breakpoint 2 is translated to the same time point as breakpoint 1, and the two breakpoints are connected by a straight line. The test load spectrum prepared by this connection method introduces a large number of singular points, which is inconsistent with the actual situation. Moreover, during the loading test, the test bed operation cannot achieve a smooth transition, which can easily lead to the test bed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com