Binder and secondary battery

A binder and structural unit technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as deterioration of battery performance, drying and cracking of pole pieces, corrosion of copper foil, etc., to simplify the feeding process without deteriorating battery performance. , The effect of improving coating yield and excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the application binding agent is:

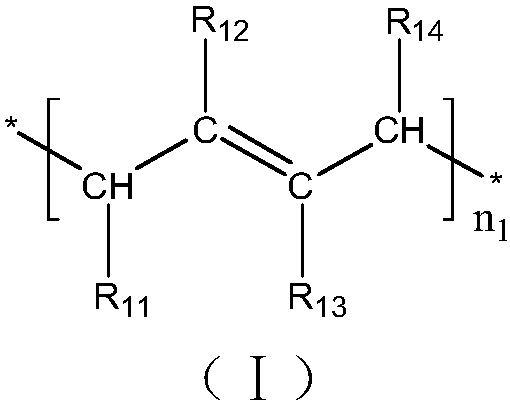

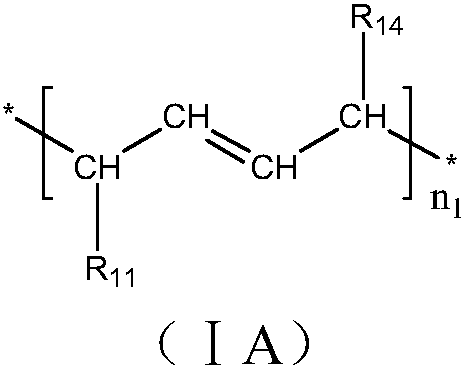

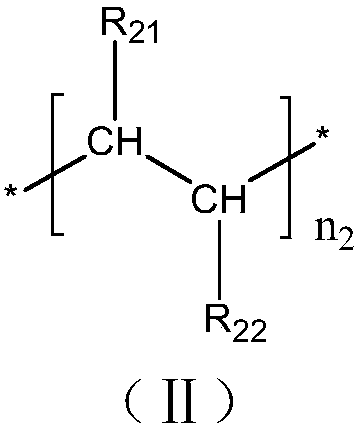

[0067] The raw materials for preparing the adhesive of this application are: butadiene shown in formula A, ethylene substituted by aromatic groups shown in formula B, ethylene substituted by ester groups or acyloxy groups shown in formula C, ethylene shown in formula D The polar group substituted ethylene:

[0068]

[0069] Among them, R 11 , R 12 , R 13 , R 14 , R 21 , R 22 , R 31 , R 32 , R 41 , R 42 The meaning expressed is the same as above.

[0070] The method for preparing the adhesive of the present application is:

[0071] Add the raw materials shown in formula A, formula B, formula C and formula D to the reactor in proportion, add initiator and molecular weight regulator, use water as solvent, and react at 60-80°C for 4-8 hours, when The number average molecular weight is 12×10 4 ~15×10 4 When the reaction is finished, the polymer of the present application is obtained.

[0072] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com