A fast reconfiguration method of live working site of live working robot system

A robot system and live working technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of virtual reality scenes that cannot be reconstructed, installation position deviation, lack of data interaction, etc., so as to save the collection and processing process and speed up The effect of refactoring speed and improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] At present, live work tasks mainly include: replacing lightning arresters, connecting drain wires, replacing isolating knife switches, and replacing drop-out fuses, etc. In this embodiment, lightning arresters, dropout fuses, pole towers, guyed insulators, and crossarms in a 10KV distribution and transmission line of a power grid are selected as modeling examples, and the on-site reconstruction of a 10KV distribution and transmission line in a certain power grid is used as an example. Specific embodiments are described in detail.

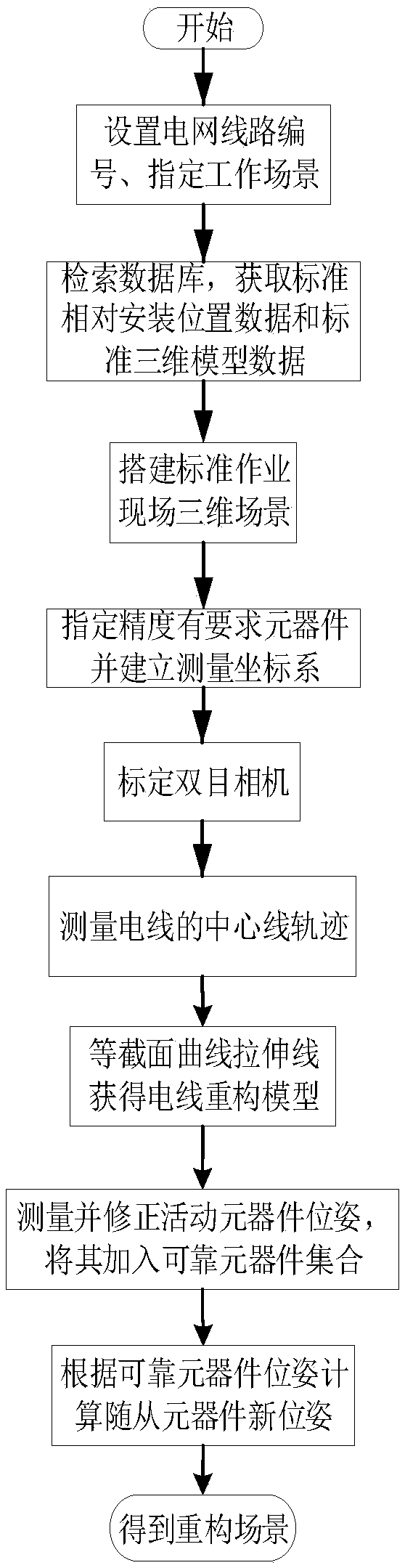

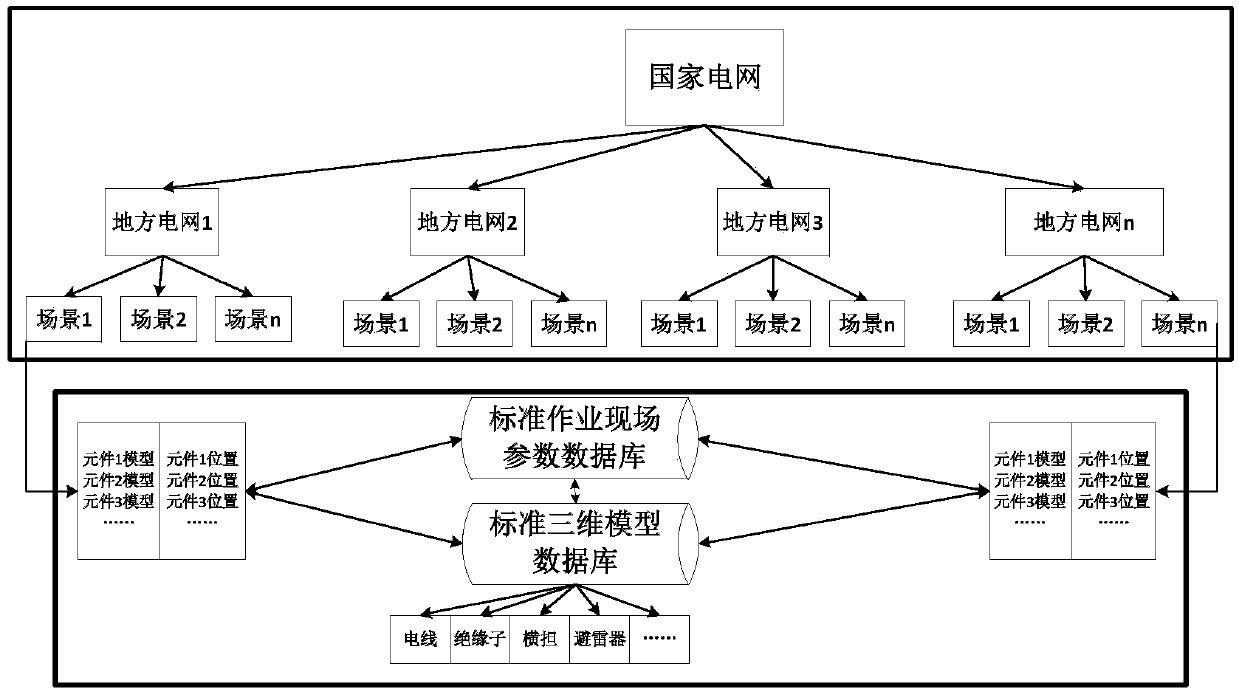

[0099] Step 1. Establish the standard operation site parameter database of various distribution and transmission lines, and construct the index structure of the system database. At present, live work tasks mainly include: replacement of drop-out fuses, replacement of lightning arresters, connection of drain wires, and replacement of isolation switches. For a specific job task, only the corresponding partial site needs to be intercepted for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com