Welding method for large-scale stainless-steel tank wallboards under high temperature environments

A technology of high temperature environment and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the inconvenience of large stainless steel tank wall panels, the inability to assemble stainless steel tank panels, and the control of the dimensional accuracy of tank panels. and other problems, to achieve the effect of good welding quality, strict design, increased confidence and courage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

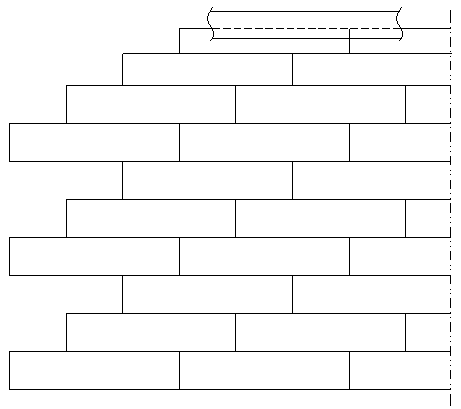

[0037] figure 1 It is a schematic diagram of the expansion of the wall plate of the stainless steel tank according to the embodiment of the present invention. The welding method of the large stainless steel tank wall plate under the high temperature environment of the present invention is typesetting according to the construction drawings and the installation position of the wall plate, and blanking is carried out according to the layout drawing of the wall plate, and the butt joint edge of the steel plate is grooved, the scale is cleaned, and the pressure is pressed. After the head is rolled on the plate rolling machine, the surface of the wall plate should be flat and smooth after the arc is rolled. After all the tank wall plates are prefabricated, based on the process of the tank upside-down method, the welding method of the tank wall plate includes the following settings according to the welding sequence A step of:

[0038] a. The welding of the vertical weld of the tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com