Non-contact air flotation claw device

A non-contact, air flotation technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of cross-contamination and scratches on glass substrates, achieve simple structure, solve cross-contamination, and stable and reliable transportation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

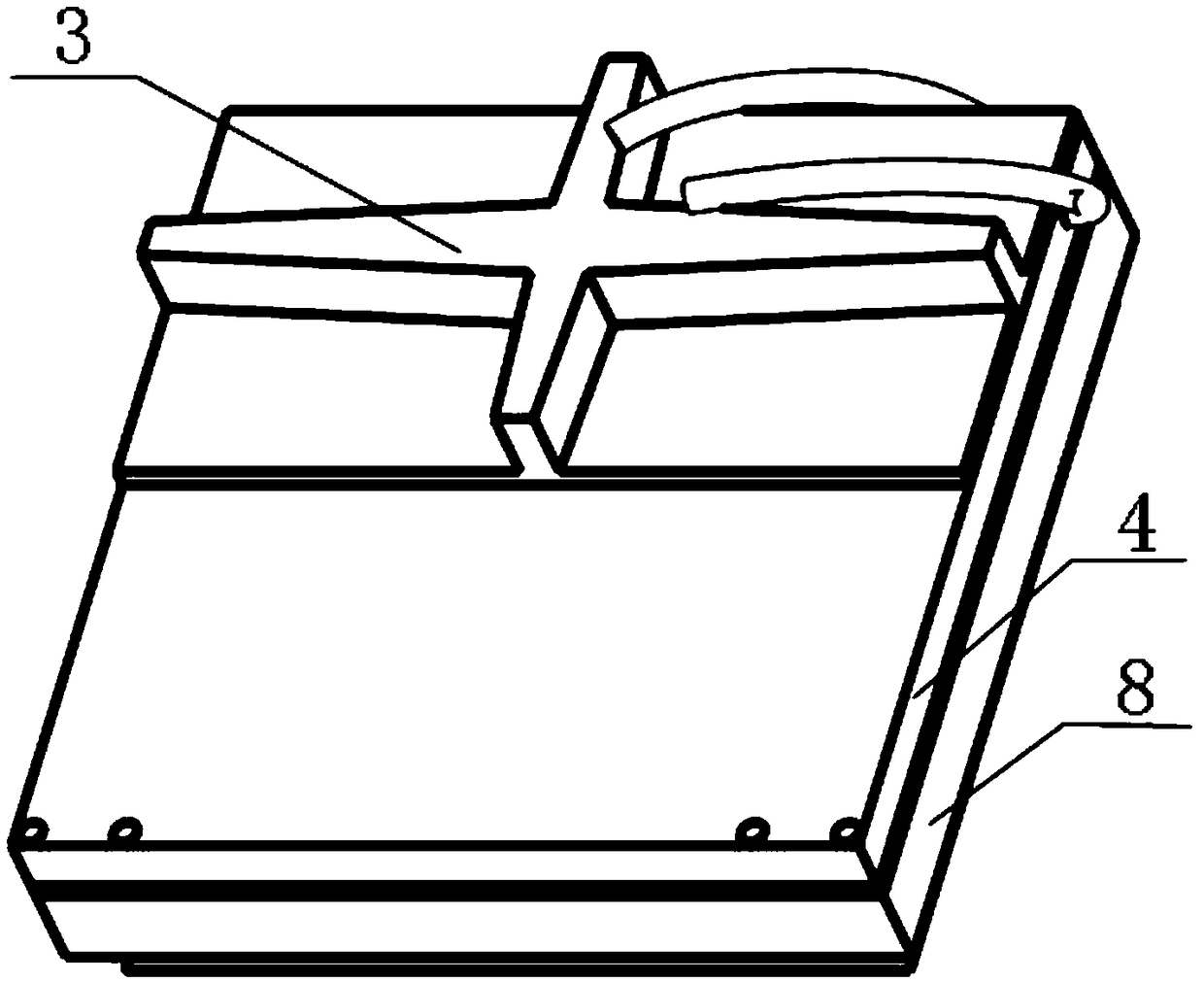

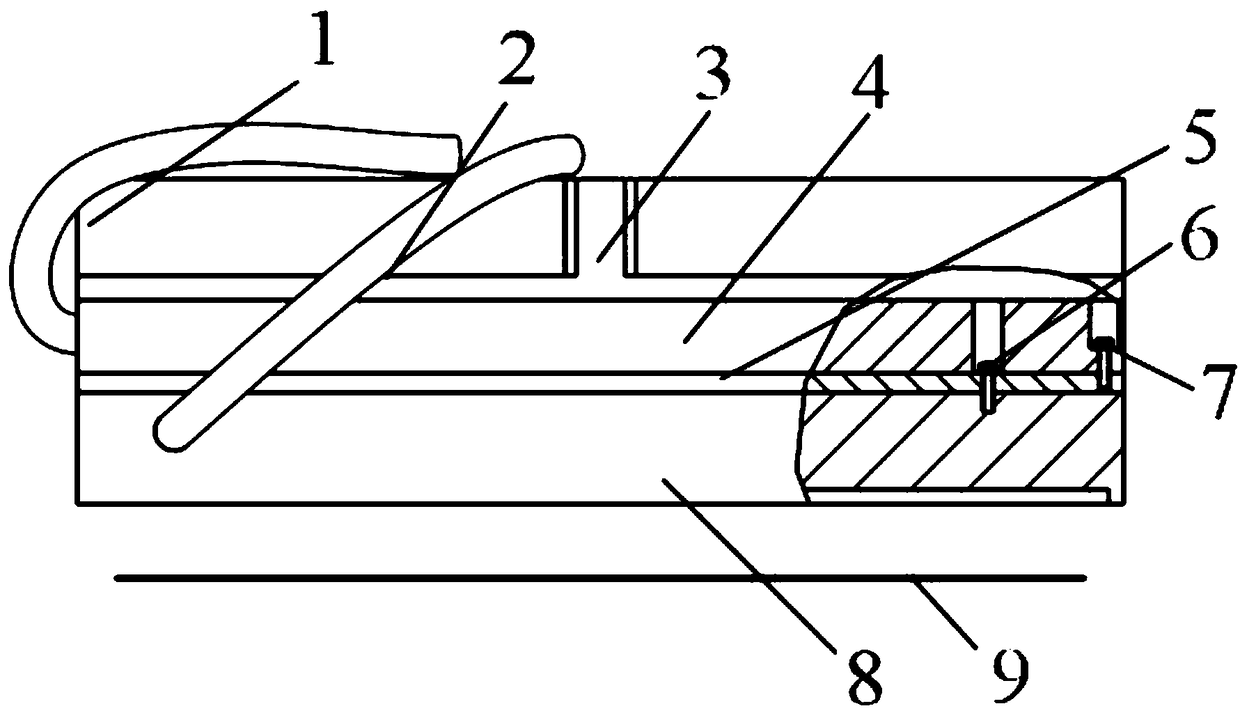

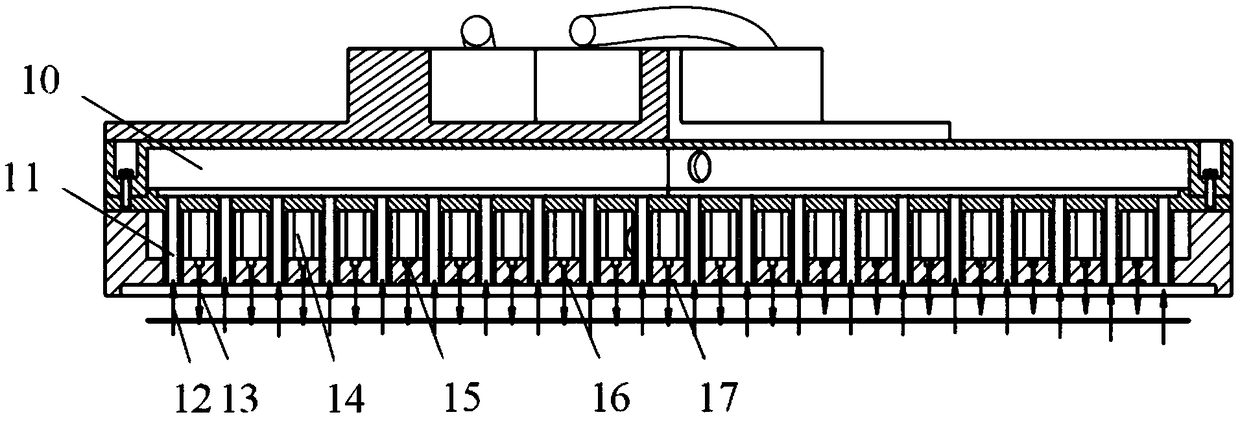

[0030] figure 1 It is a perspective view of an embodiment of a non-contact air bearing claw device of the present invention; figure 2 It is a front view of an embodiment of a non-contact air bearing claw device of the present invention; image 3 It is a cross-sectional view of Embodiment 1 of a non-contact air bearing claw device of the present invention; Figure 4 It is a bottom view of Embodiment 1 of a non-contact air bearing claw device of the present invention. In this embodiment, the non-contact air flotation claw device mainly includes negative pressure air pipe 1, positive pressure air pipe 2, air flotation suction cup adapter 3, negative pressure housing 4, negative pressure adapter plate 5, thread tight Firmware 6, threaded fasteners 7, positive pressure housing 8, glass substrate 9, negative pressure air cavity 10, negative pressure orifice 11, negative pressure air flow 12, positive pressure air flow 13, positive pressure air cavity 14, positive pressure Buffer...

Embodiment 2

[0041] figure 1 It is a perspective view of an embodiment of a non-contact air bearing claw device of the present invention; figure 2 It is a front view of an embodiment of a non-contact air bearing claw device of the present invention; Figure 5 It is a cross-sectional view of Embodiment 2 of a non-contact air bearing claw device of the present invention; Figure 6 It is a bottom view of Embodiment 2 of a non-contact air bearing claw device of the present invention. In this embodiment, the non-contact air flotation claw device mainly includes negative pressure air pipe 1, positive pressure air pipe 2, air flotation suction cup adapter 3, negative pressure housing 4, negative pressure adapter plate 5, thread tight Firmware 6, threaded fastener 7, positive pressure housing 8, glass substrate 9, negative pressure air cavity 20, negative pressure microhole 21, negative pressure airflow 22, positive pressure airflow 23, positive pressure microhole 24, positive pressure Micropo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com