Multi-stage dual-cycle-period sewage treatment system

A sewage treatment system and double-circulation technology, applied in multi-stage water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor filtering effect, filter blockage, and inconvenient realization, and achieve Improve efficiency, occupy less space, and have ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

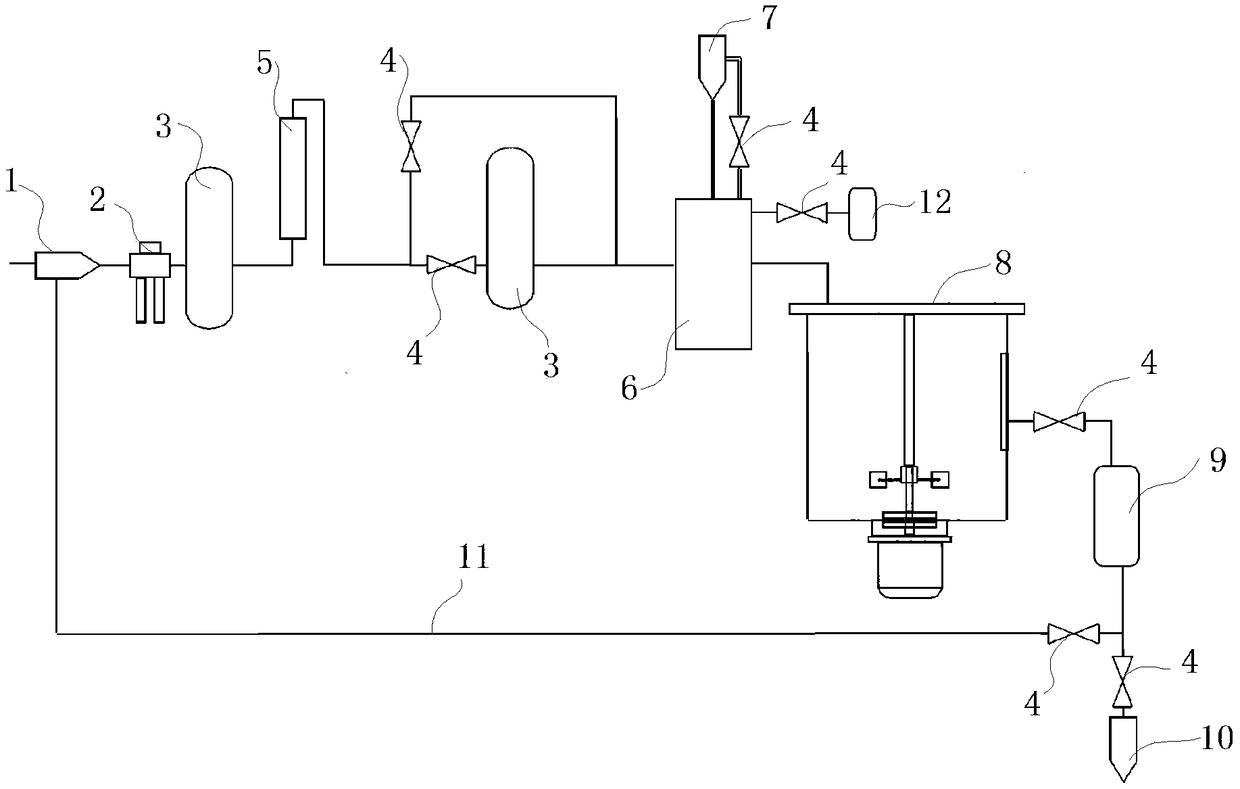

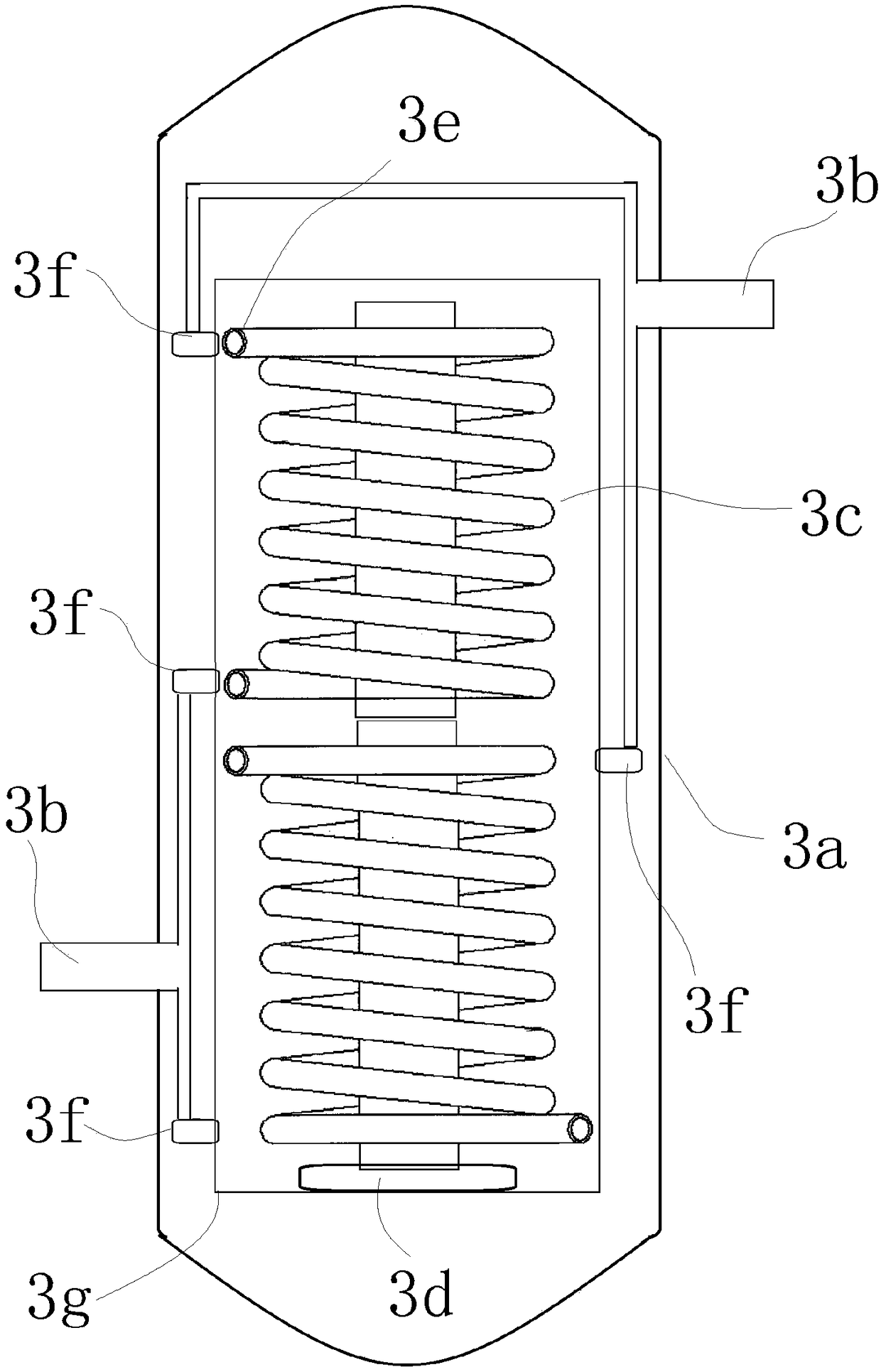

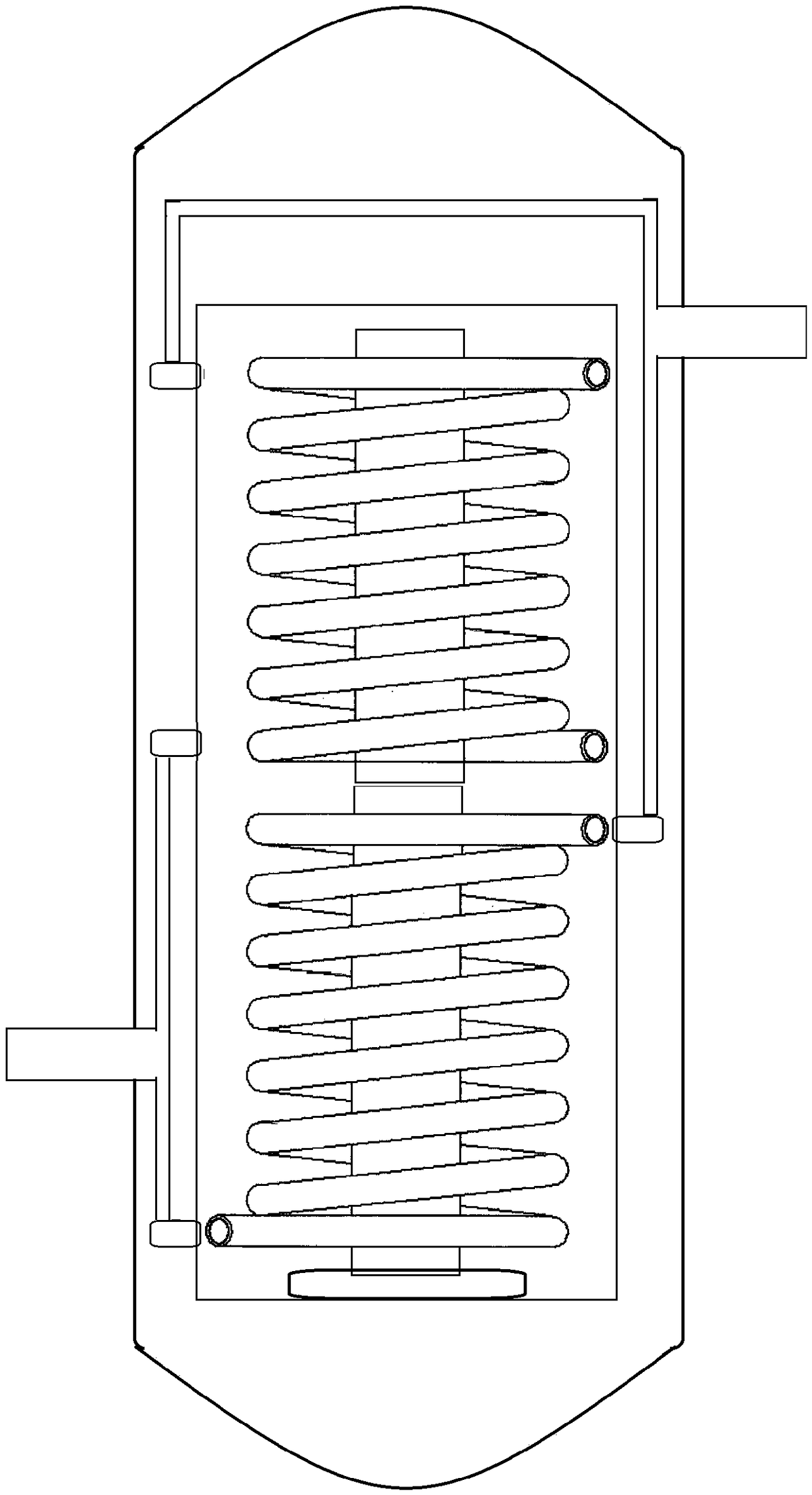

[0029] exist figure 1 In the shown embodiment, the present invention includes a sewage inlet 1, a water pump 2, a spiral filter 3, a control valve 4, a circulation filter 5, an aeration tank 6, an air source port 7, a separation and purification tank 8, and a quality inspection tube 9 , Outlet 10, circulation pipe 11, gas recovery pump 12. The sewage inlet 1 is sequentially connected to the water pump 2 for providing water pressure, the spiral filter 3 for coarse filtration, and the circulation filter 5 for fine filtration through pipelines, and the circulation filter 5 is connected to the aeration tank 6 in sequence through pipelines and the separation and purification tank 8, wherein the upper part of the aeration tank 6 is connected to the gas source port 7 through an air inlet pipe, the upper part of the aeration tank 6 is also connected to the gas source port 7 through a gas outlet pipe, and the upper part of the aeration tank 6 is also connected to the gas source port 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com