Wine-making skin-pressing device and method

A wine and skin-pressing technology is applied in the preparation of wine, biochemical equipment and methods, preparation of alcoholic beverages, etc., and can solve problems such as affecting the normal fermentation of wine, easily falling into impurities in fermentation barrels, and low degree of automation. Overall weight and cost, low weight, high automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

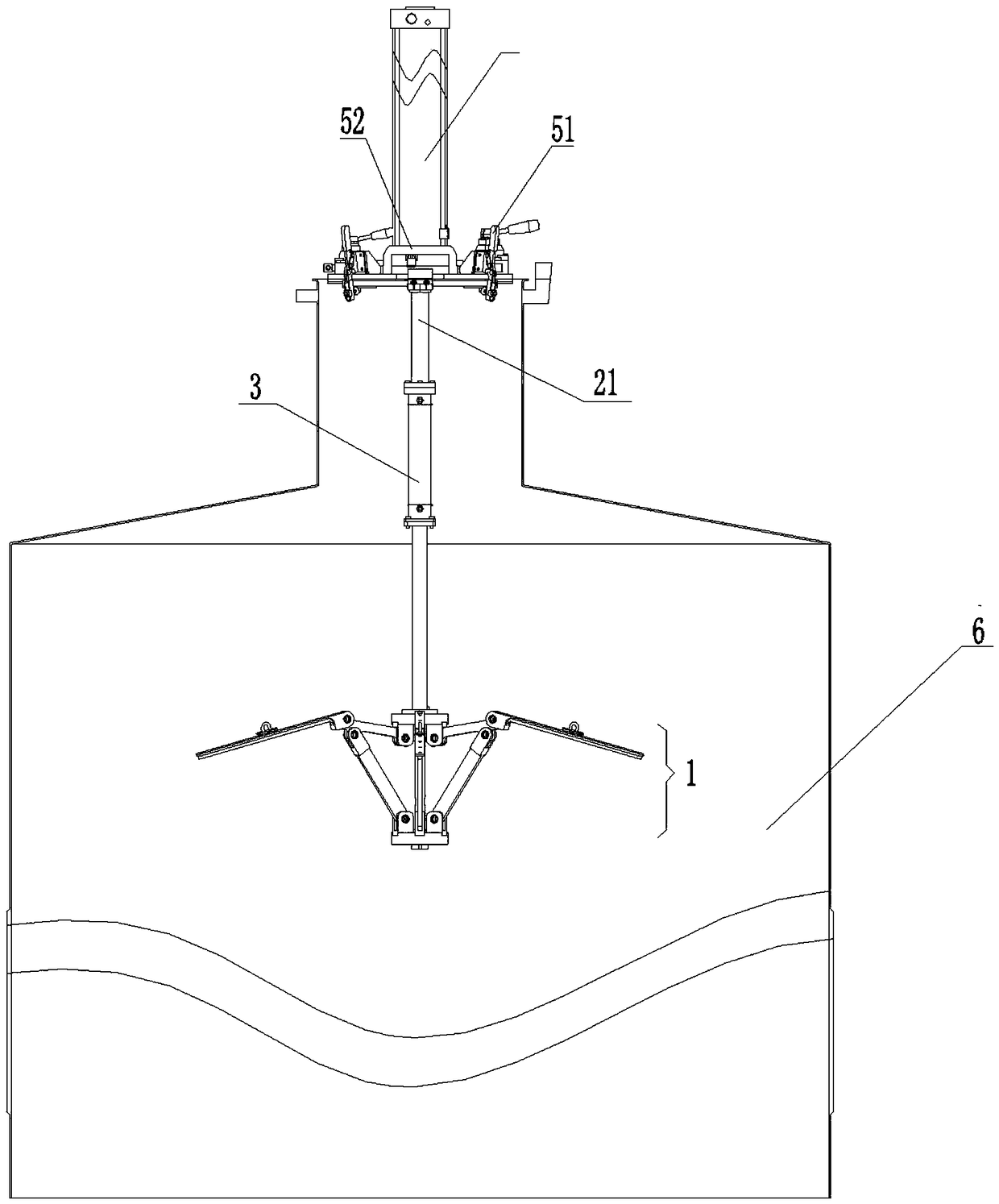

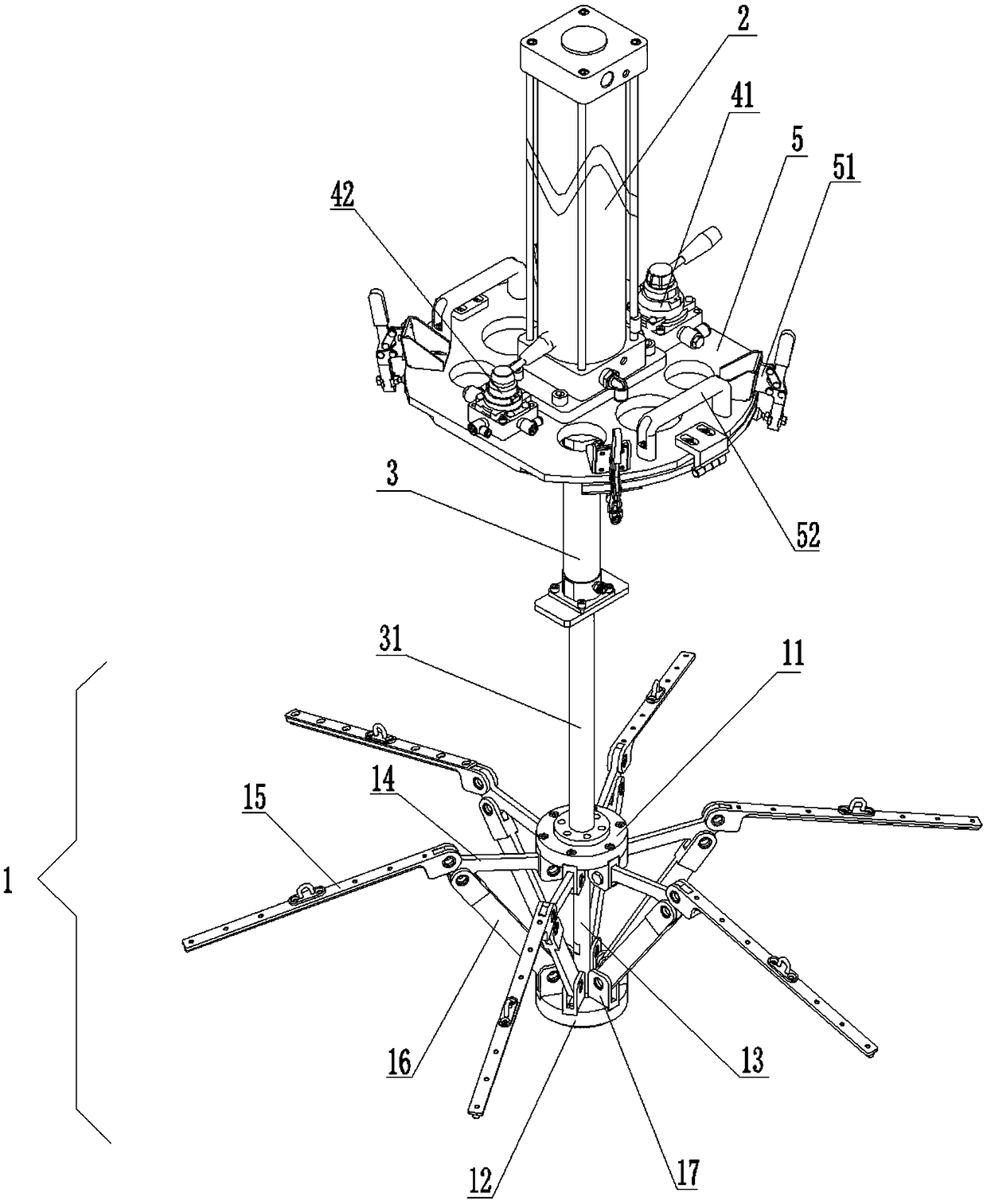

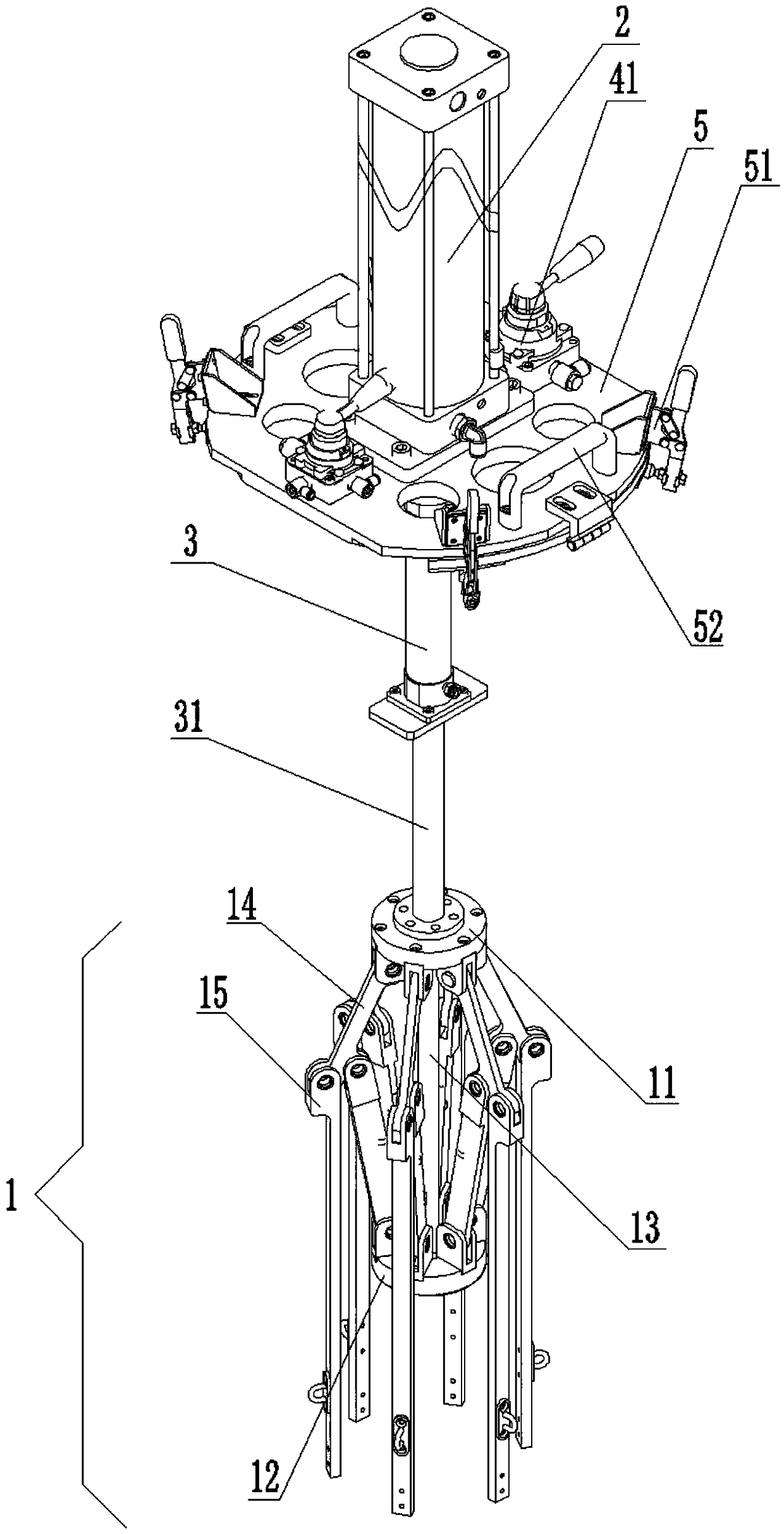

[0027] The wine brewing pressing device provided by the present invention comprises an umbrella-shaped pressing cap 1, a lifting cylinder 2 for controlling the position of the umbrella-shaped pressing cap in the fermenter, an umbrella cover cylinder 3 for controlling the opening and contraction of the umbrella-shaped pressing cap, and the umbrella cover cylinder passes through The connecting rod is connected with the umbrella gland, and the lifting cylinder is connected with the umbrella cover cylinder through the telescoping rod, and the working states of the two cylinders are respectively controlled by the first control valve 41 and the second control valve 42 .

[0028] First, adjust the telescoping rod 21 of the umbrella-shaped pressing cap 1 and the lifting cylinder 2 to the contracted state, extend the umbrella-shaped pressing cap and the umbrella cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com