A Performance Degradation Evaluation Method of Turbine Engine Based on Stacked Denoising Autoencoder

A turbine engine and self-encoder technology, applied in gas turbine engine testing, jet engine testing, etc., can solve the problems of lack of generality, lack of consistent standards, time-consuming training label selection, etc., to improve time correlation, avoid interference, The effect of reducing the involvement of human and expert experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

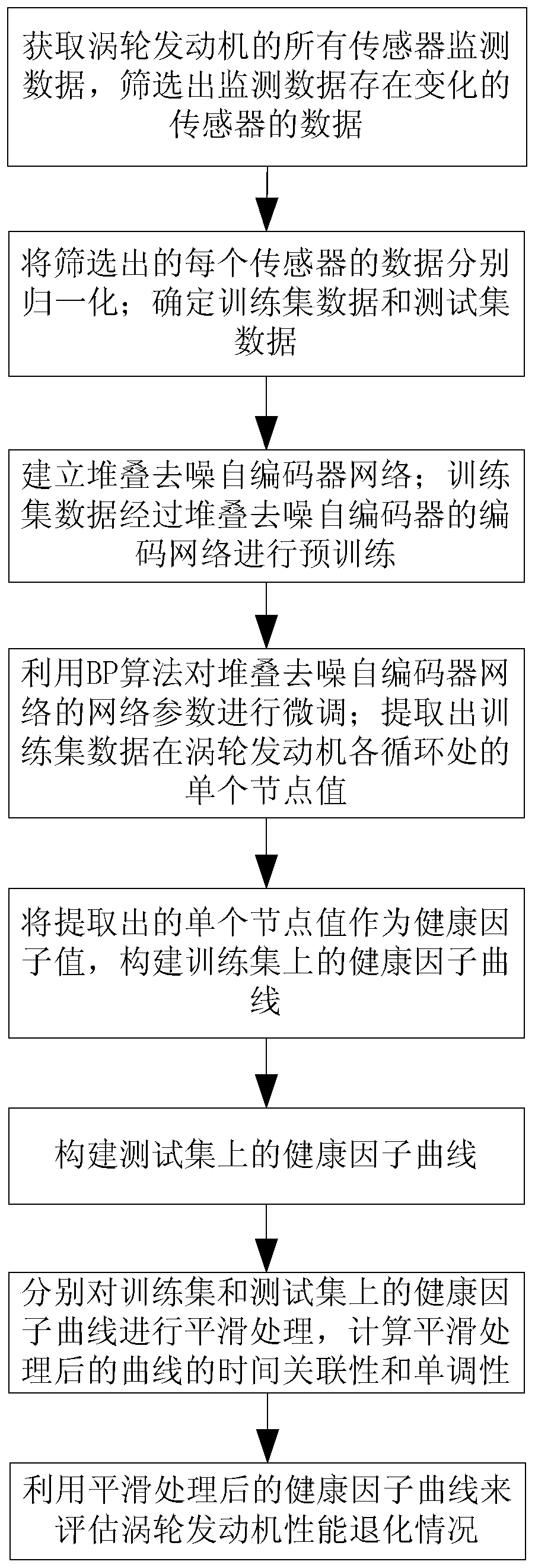

[0035] Specific implementation mode one: combine figure 1 with figure 2 This embodiment will be described. A method for evaluating performance degradation of a turbine engine based on a stacked denoising autoencoder described in this embodiment, the specific steps of the method are:

[0036] Step 1. Use N monitoring units to obtain all sensor monitoring data of the turbine engine; observe and filter out the data x of sensors whose monitoring data changes k , k=1,2,...,Q, Q is the number of sensors whose monitoring data changes;

[0037] Step 2. The data x of each sensor screened out in step 1 k Normalize to the [0,1] interval respectively; the sensor data of a part of the monitoring unit after screening is used as the training set data, and the sensor data of the other part of the monitoring unit is used as the test set data;

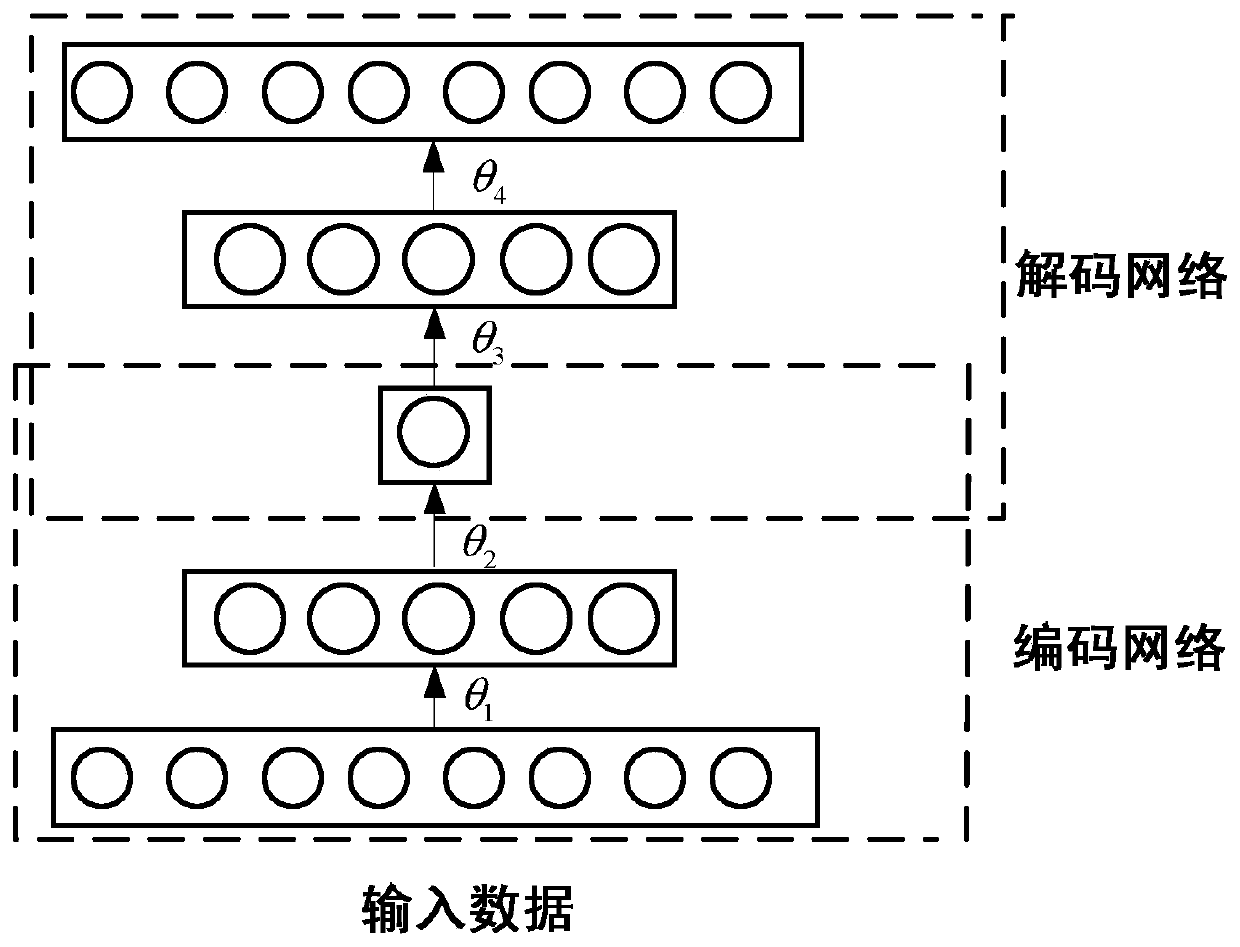

[0038] Step 3: Establish a stacked denoising autoencoder network composed of four denoising autoencoders for feature extraction of training set da...

specific Embodiment approach 2

[0048] Specific Embodiment 2: This embodiment further defines the turbine engine performance degradation evaluation method based on stacked denoising autoencoder described in Embodiment 1. In the second step, the data of each sensor is normalized The process is:

[0049] Normalized by x k * =(x k -x k,min ) / (x k,max -x k,min ), where x k * is each sensor data x k Normalized value, x k,max and x k,min Corresponding to the maximum and minimum values of each sensor in each cycle of the turbine engine, respectively.

specific Embodiment approach 3

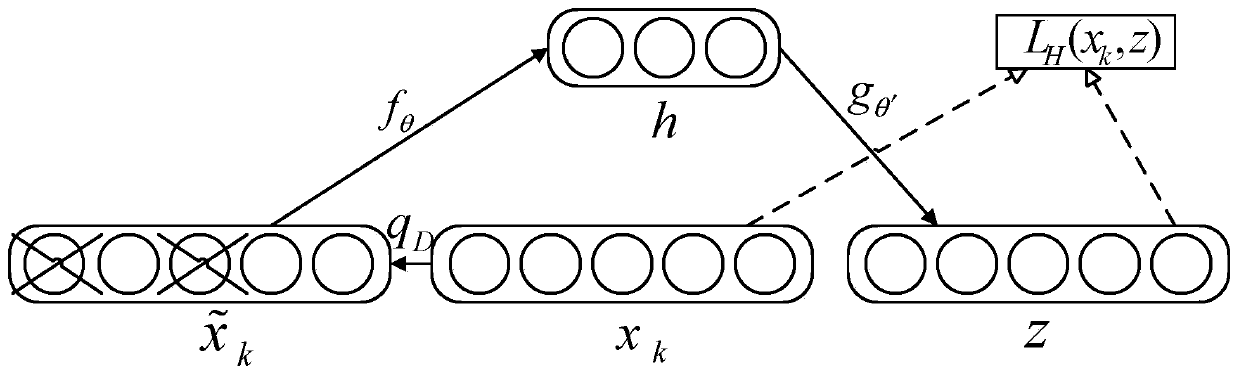

[0050] Specific implementation mode three: combination image 3 This embodiment will be described. This embodiment further defines the turbine engine performance degradation evaluation method based on the stacked denoising autoencoder described in the second embodiment. The working principle of the first denoising autoencoder is as follows:

[0051] The training set data is used as the input data of the first denoising autoencoder of the stacked denoising autoencoder network, and the first denoising autoencoder passes the random mapping function q D For input data x k Destroy and get the data after adding noise After encoding process f θ1 Generate the output of the hidden layer The output of the hidden layer After the decoding process g θ1' Generate reconstructed data z; input data x k The difference with the reconstructed data z is taken as the reconstruction error L H (x k , z) for training;

[0052] Encoding process f θ1 The specific process is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com