High-precision automatic inspection method and system based on unmanned aerial vehicle

An automatic inspection and unmanned aerial vehicle technology, applied in control/regulation systems, vehicle position/route/height control, non-electric variable control, etc., can solve problems such as increasing labor intensity, reducing operating efficiency, and increasing risk of action , to achieve the effect of improving operation efficiency, improving efficiency and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

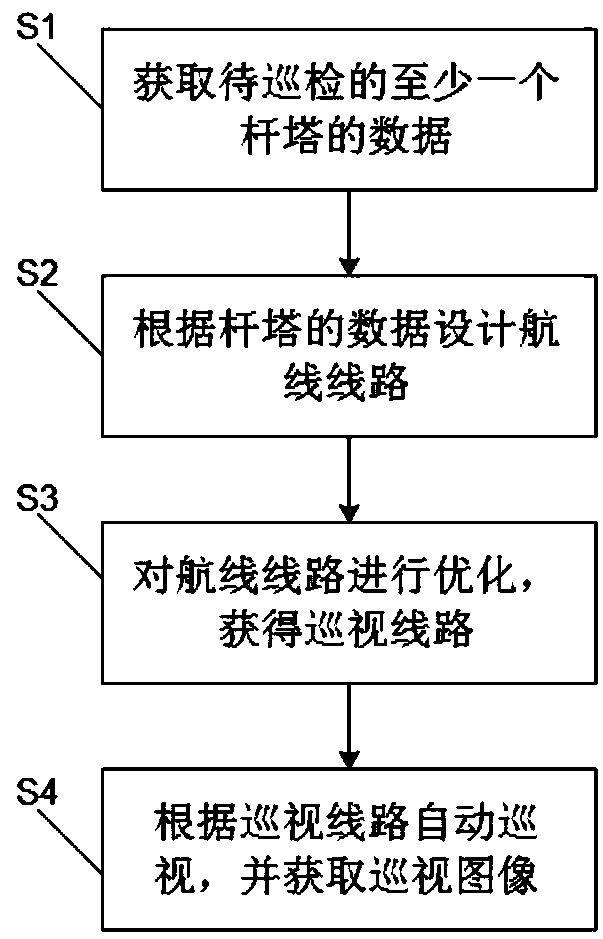

[0047] see figure 1 , which is a flowchart of a high-precision automatic inspection method based on a drone in an embodiment of the present invention. The described high-precision automatic inspection method based on unmanned aerial vehicles may further comprise the steps:

[0048] Step S1: Obtain data of at least one tower to be inspected.

[0049] In one embodiment, the power tower line is imported in the form of a kml file, and all towers of the line are displayed in order, and the user can select one tower or multiple towers for inspection. The data of the tower includes the name of the line where the tower is located, the number of the tower, the latitude and longitude of the tower, the height of the tower, the altitude of the tower and the circuit information of the tower.

[0050] Step S2: Design the flight line according to the data of the tower.

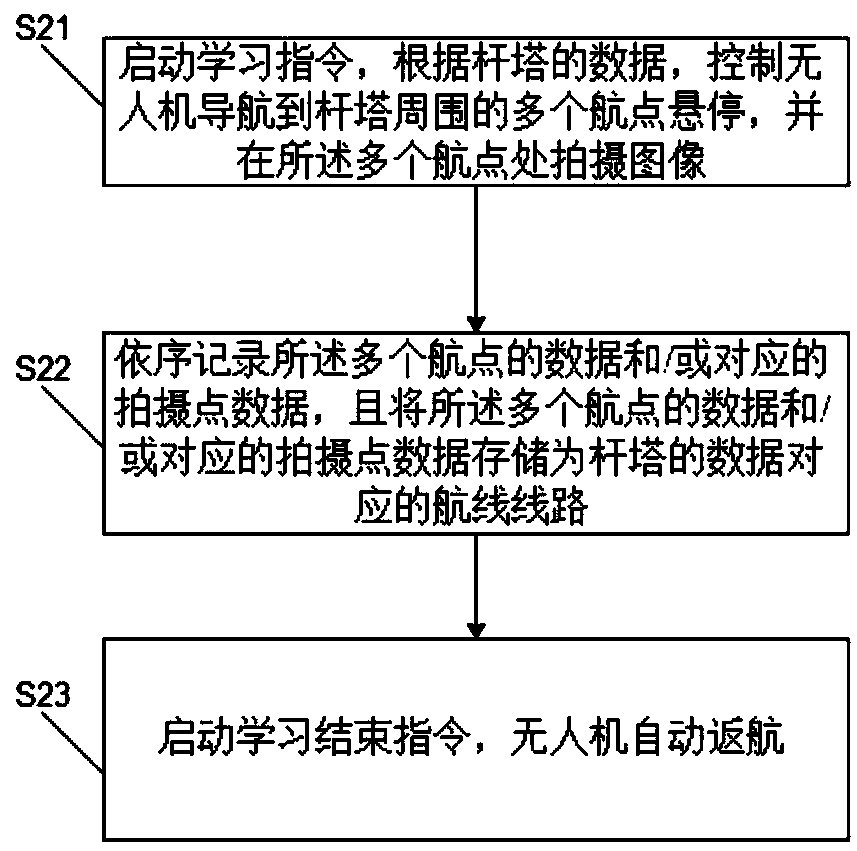

[0051] see figure 2 , which is a flow chart of generating airline routes in the embodiment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com