A novel method for multidisciplinary automatic optimization design of an axial flow pump impeller

A technology of automatic optimization and optimal design, applied in computing, special data processing applications, instruments, etc., can solve problems such as lack of perfect combination of hydraulic design and structural design, insufficient reliability and accuracy of optimized design results, and failure to achieve coordinated design. , to achieve the effect of light blade quality, small blade stress value and vibration displacement, and consistent rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

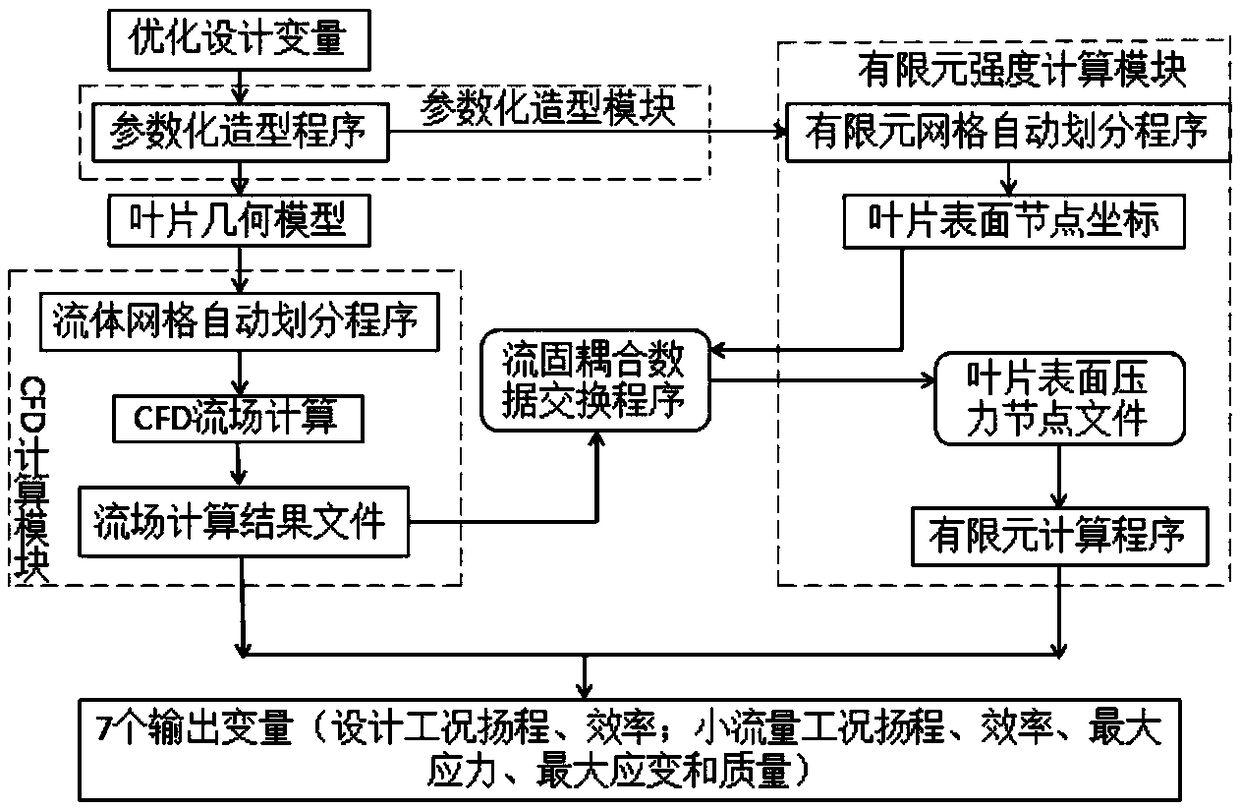

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0042] (1) Parametric modeling of axial flow pump impeller

[0043] Generally, when designing the impeller of an axial flow pump, the blades of the axial flow pump are divided into 11 two-dimensional airfoil sections for design. Then the designed cross-section airfoils are smoothly combined into an axial flow pump impeller. Cascade density (l / t) is an important parameter in the design of axial flow pump blades, l: refers to the chord length of the airfoil section; t=2πr / z, where z is the number of blades, r is the location of the airfoil section Radius value. The tip cascade density refers to the cascade density value of the airfoil section at the outermost edge of the blade, and the blade root cascade density refers to the cascade density value of the airfoil section at the hub. The density multiple of the root cascade refers to the ratio of the density o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com