A method for cyclic formation of low current disturbance in the vicinity of high SOC of lithium battery

A chemical formation method and lithium battery technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of cumbersome operation process and battery cycle performance to be improved, so as to improve long cycle life and improve The effect of flat uniformity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

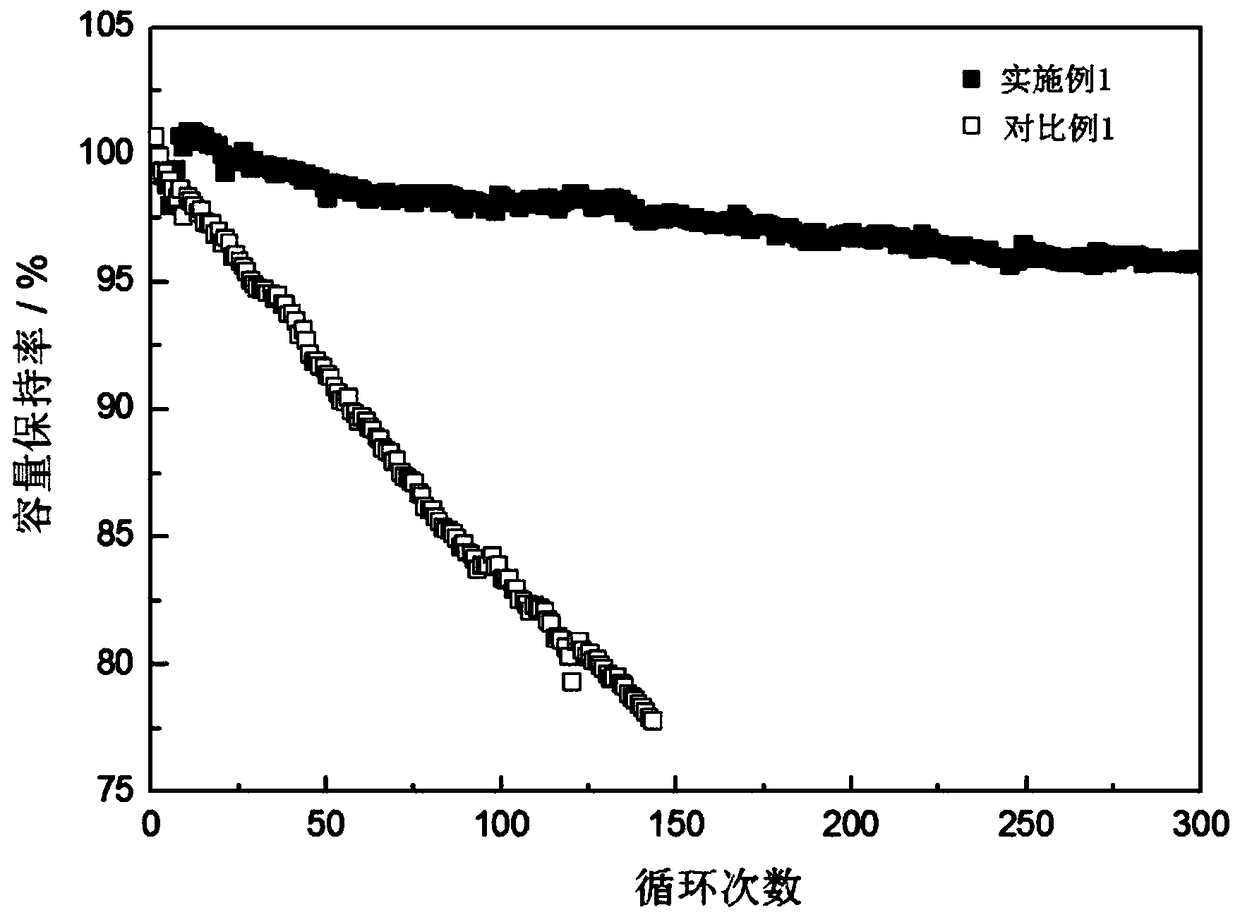

Embodiment 1

[0046] In this example, an open-ended chemical formation process is adopted, and the whole process of chemical formation is carried out at a high temperature of 55°C; the details are as follows:

[0047] (1) Charge the lithium battery to 60% SOC at a charging rate of 0.3C, and let it stand for 1 hour;

[0048] (2) Charge the lithium battery to 69% SOC at a charging rate of 0.1C, then discharge the lithium battery to 60% SOC at a discharging rate of 0.1C, and use the above process to cycle charge and discharge the lithium battery for 3 times. During the discharge process, the battery is vacuum treated at the same time, and the vacuum degree is -0.08MPa. After the cycle is over, it is left to stand for 1h;

[0049] (3) Discharge the lithium battery to a lower limit voltage of 3.0V at a discharge rate of 0.3C.

[0050] In this embodiment, the formation time is about 12 hours.

Embodiment 2

[0052] In this example, an open-ended chemical formation process is adopted, and the whole process of chemical formation is carried out at a high temperature of 55°C; the details are as follows:

[0053] (1) Charge the lithium battery to 80% SOC at a charging rate of 0.8C, and let it stand for 1 hour;

[0054] (2) Discharge the lithium battery to 77% SOC with a discharge rate of 0.2C, and then charge the lithium battery to 80% SOC with a charge rate of 0.05C, and use the above process to cycle charge and discharge the lithium battery for 7 times. During the discharge process, the battery is vacuum treated at the same time, and the vacuum degree is -0.06MPa. After the cycle is over, it is left to stand for 1h;

[0055] (3) Discharge the lithium battery to a lower limit voltage of 3.0V at a discharge rate of 0.3C.

[0056] In this embodiment, the formation time is about 8 hours.

Embodiment 3

[0058] In this example, an open-ended chemical formation process is adopted, and the whole process of chemical formation is carried out at a high temperature of 55°C; the details are as follows:

[0059] (1) Charge the lithium battery to 50% SOC at a charging rate of 0.5C, and let it stand for 1 hour;

[0060] (2) Charge the lithium battery to 55% SOC at a charging rate of 0.05C, and then discharge the lithium battery to 50% SOC at a discharging rate of 0.05C, and use the above process to cycle charge and discharge the lithium battery for 5 times. During the discharge process, the battery is vacuum treated at the same time, and the vacuum degree is -0.06MPa. After the cycle is over, it is left to stand for 1h;

[0061] (3) Discharge the lithium battery to a lower limit voltage of 3.0V at a discharge rate of 0.5C.

[0062] In this embodiment, the formation time is about 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com