Lifting-type traction-free kelp lifting, transporting and cutting system and working method thereof

A cutting system and lifting system technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as kelp damage, and achieve the effects of comprehensive consideration, avoidance of damage, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

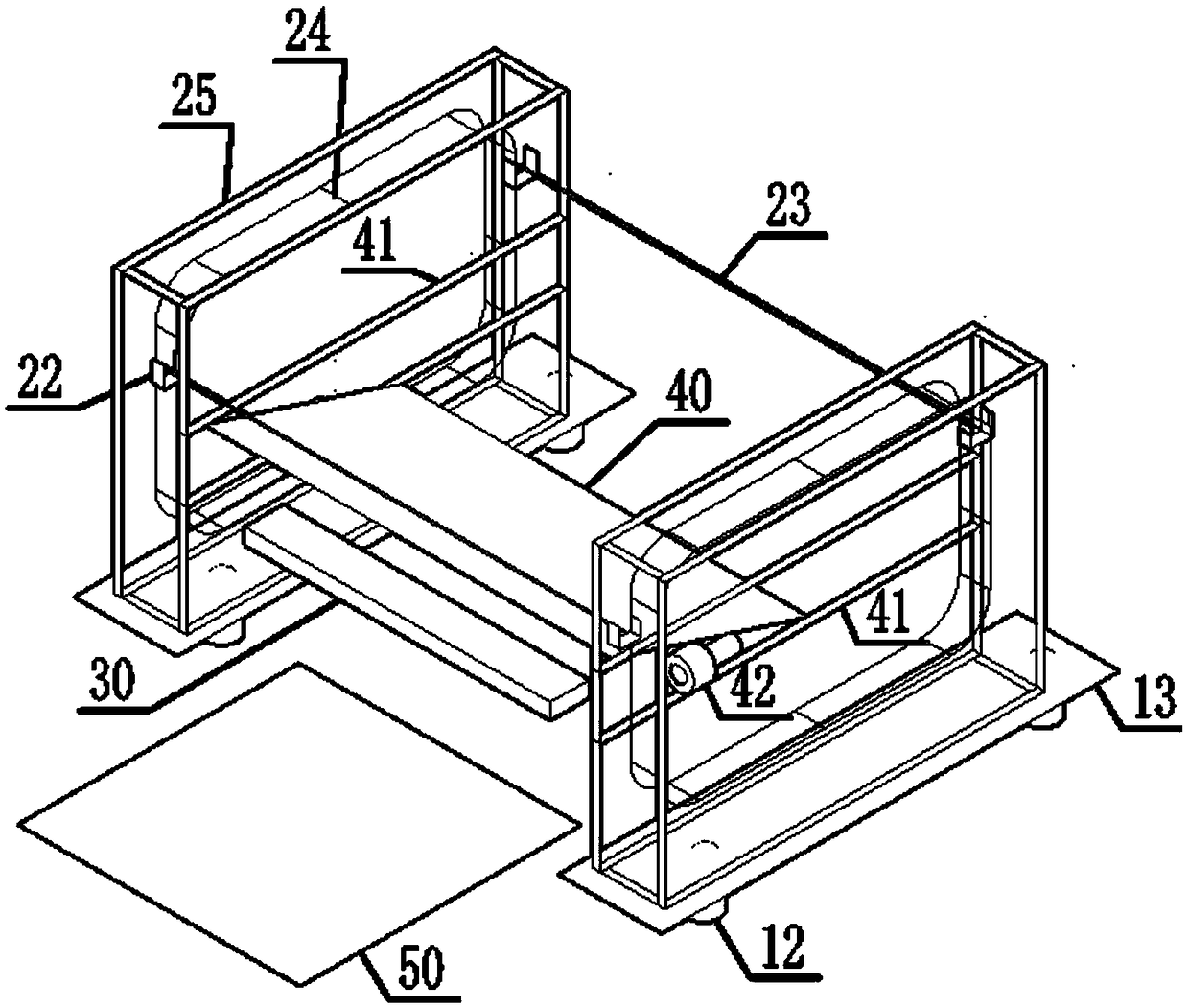

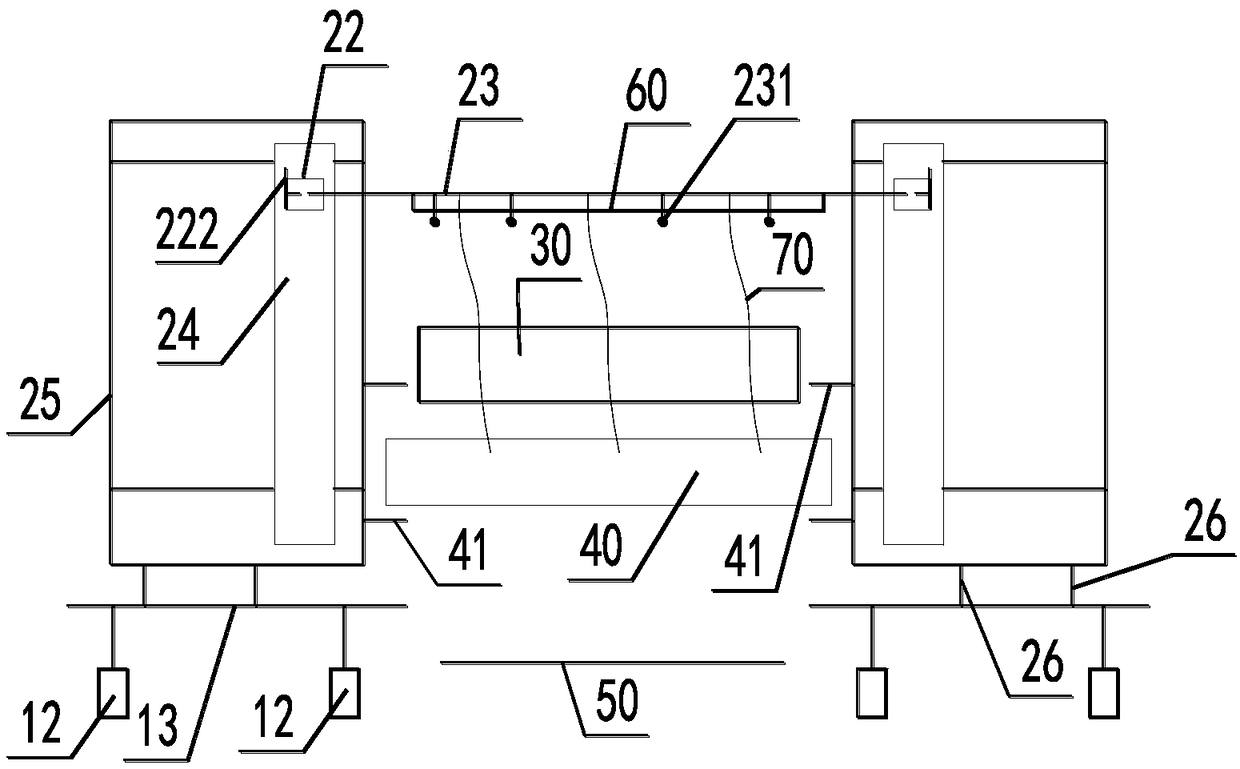

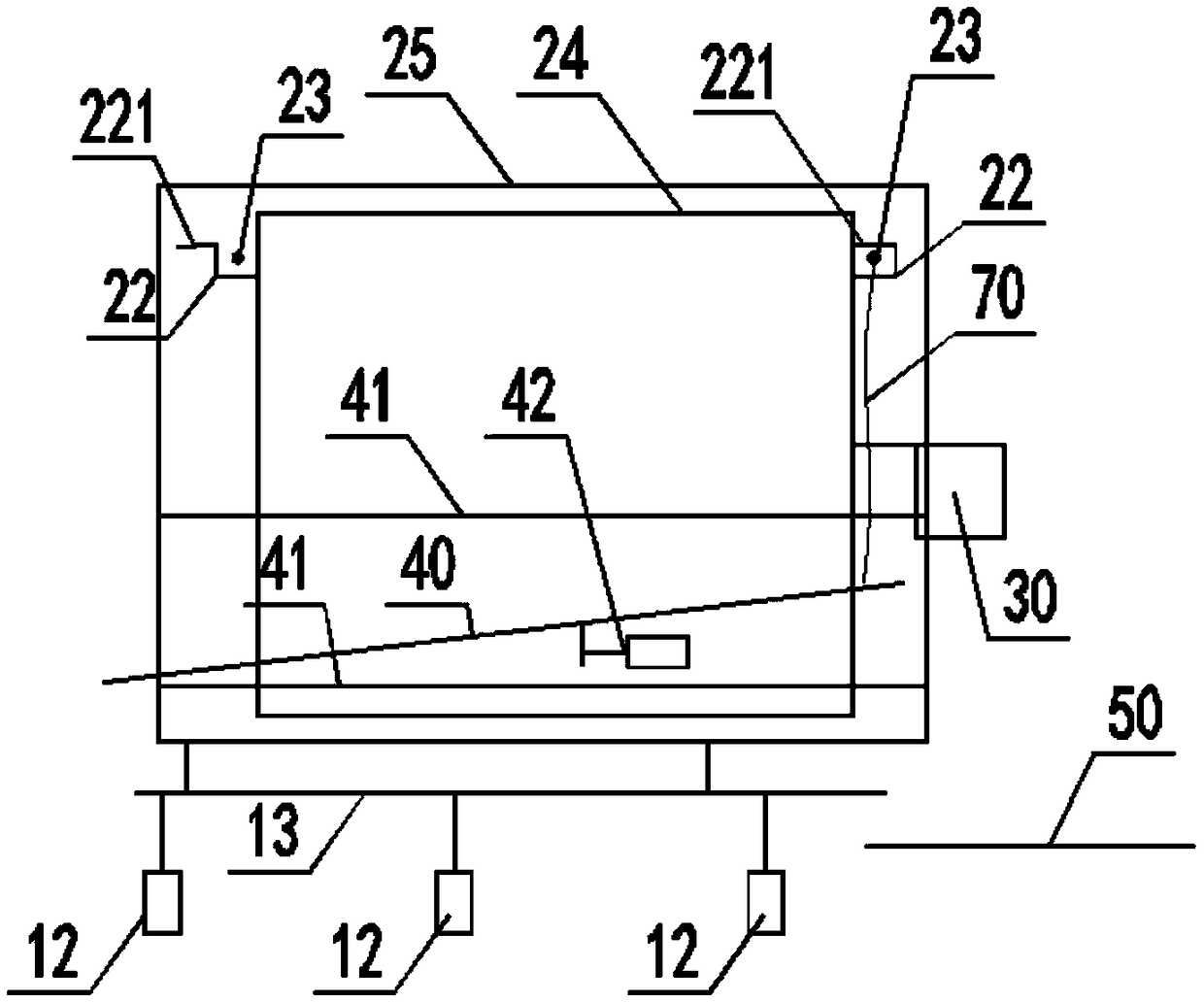

[0027] see Figure 1-Figure 6 , a lift-free drag-free kelp lifting and cutting system, comprising: a lifting system consisting of a pair of synchronously moving lifting units 11; a lifting system consisting of a pair of synchronously moving kelp lifting units 21, the kelp lifting unit 21 As for the lifting unit 11, it moves up and down together with the lifting unit 11; the sea-tangle lifting unit 21 itself is a transmission system that is vertically arranged and closed from head to tail; the rear area between a pair of sea-tangle lifting units 21 is fixedly provided with a cutting system 30, The front of the cutting system 30 is provided with a slideway 40 with a low front and a high rear to receive and transfer the cut kelp tip; the cutting system 30 is directly below the rear laying conveyor system 50 to accept and transfer the cut kelp body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com