Semi-automatic squid de-epidermis device

A semi-automatic squid technology, applied in the processing and slaughtering of fish and cephalopods, can solve the problems of squid surface damage, high work intensity, and slow processing speed, and achieve convenient operation, simple structure, and continuous production Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now do further detailed explanation in conjunction with accompanying drawing.

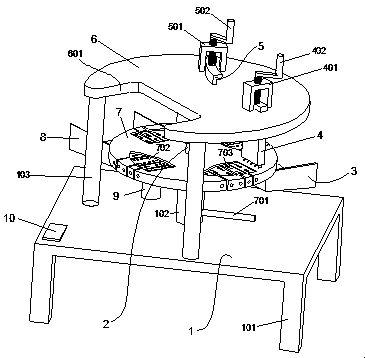

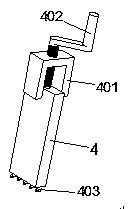

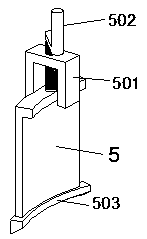

[0025] Such as Figures 1 to 5 As shown, a semi-automatic squid skin removal device includes a frame 1, a motor 2, a waste hopper 3, a cutter 4, a scraper 5, a fixed plate 6, a turntable 7, a hopper 8, a cylinder 9, a PLC 10, and a top seat 11.

[0026] Such as Figure 1-5 As shown, the setting frame 1 is the main mounting frame, and there are 4 feet 101 under it. The turntable 7 is installed on the frame 1 through the circular shaft 102, and the motor 2 drives it to rotate around the circular shaft 102. There are 4 discharge slots 702 evenly distributed on the upper surface, and a vacuum suction system 701 is arranged inside the board. The discharge slot is an arc Shaped, the depth is 1.0-1.5mm, it is an outward taper, the discharge trough 702 has three avoidance grooves, and a number of rows of fine holes 703 are arranged inside; The air path 7012, the circular air path is divided into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com