Drying and extrusion device for pickling of green plums

An extrusion device and drying technology, applied in the field of drying and extrusion devices for greengage pickling, can solve the problems of loss, difficulty in controlling the extrusion force, damage to greengage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

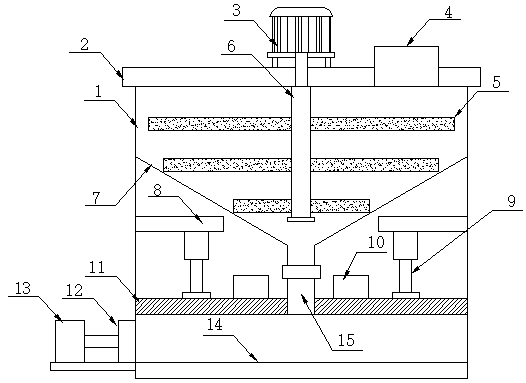

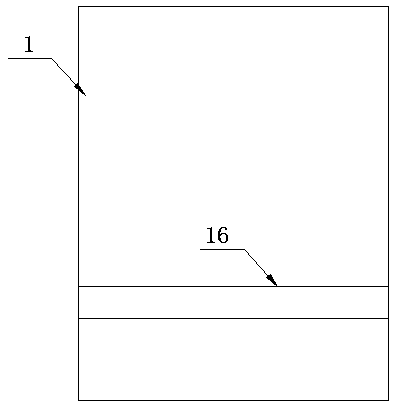

[0016] Such as Figure 1-3 As shown, the present invention discloses a drying and extrusion device for pickling green plums, comprising: a body 1, a cover plate 2, and a feed port 4, the top of the body 1 is provided with a cover plate 2, and one end of the cover plate 2 is provided There is a feed port 4, the top of the cover plate 2 is provided with a motor bracket, and the top of the motor bracket is provided with a servo motor 3, and the servo motor 3 is connected to a rotating shaft 6 through its own motor shaft, and the rotating shaft 6 Cleaning cotton rollers 5 of different lengths are fixedly connected to the top, and a plurality of material guide covers 7 are obliquely arranged in the body 1 .

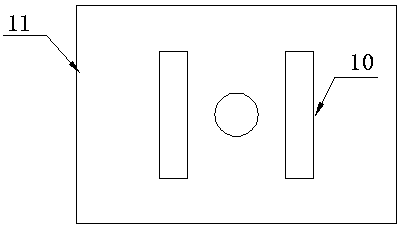

[0017] The two inner walls of the body 1 are fixedly connected with connecting plates 8 arranged horizontally, the bottom of the connecting plate 8 is provided with a lifting cylinder 9, and one end of the piston rod of the lifting cylinder 9 is fixedly connected with a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com