A vocs industrial waste gas treatment system

A treatment system and industrial waste gas technology, applied in gas treatment, separation methods, transportation and packaging, etc., can solve the problems of secondary pollution, increased cost of VOCs waste gas treatment, low efficiency of VOCs waste gas treatment, etc., to reduce the catalytic effect and improve effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

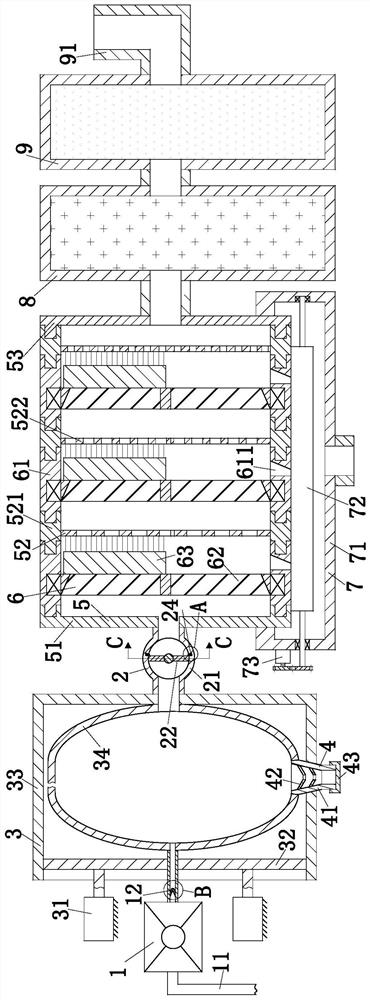

[0026] use Figure 1 to Figure 7 The VOCs exhaust gas treatment device according to one embodiment of the present invention will be described as follows.

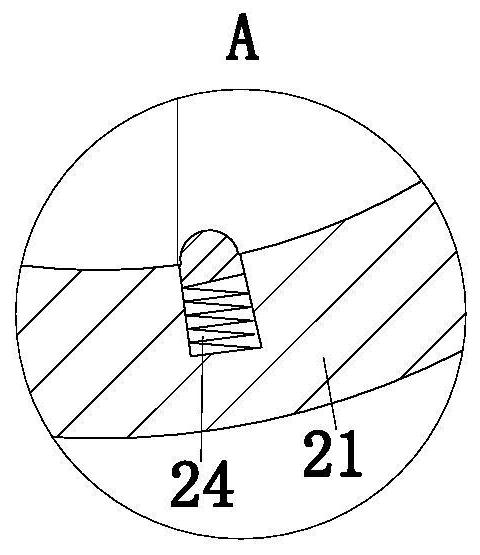

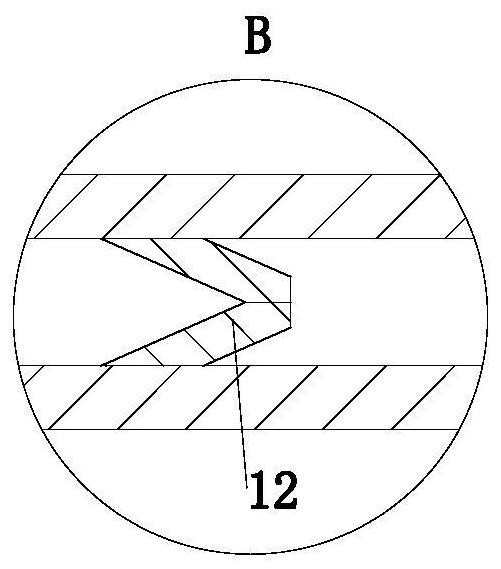

[0027] Such as figure 1 and image 3 As shown, a VOCs industrial waste gas treatment system according to the specific embodiment of the present invention includes an air pump 1, a waste gas collection pipe 11, an air blowing module 3, a filtering module 5, a dust sweeping module 6, a UV photocatalytic processor 8, Plasma processor 9 and exhaust pipe 91, one end of the air pump 1 communicates with the waste gas collection pipe 11, the other end of the air pump 1 communicates with the air blowing module 3, and the air extractor 1 is used to extract waste gas and transport the waste gas to the air blower In the module 3; the air blowing module 3 communicates with the filter module 5, and the air blowing module 3 is used for intermittently blowing exhaust gas into the filter module 5; the filter module 5 is integrated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com