A kind of microcapsule formaldehyde remover and preparation method thereof

A formaldehyde remover and microcapsule technology, applied in the field of microcapsule formaldehyde remover and its preparation, can solve the problems of insignificant effect, slow adsorption, unstable product and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

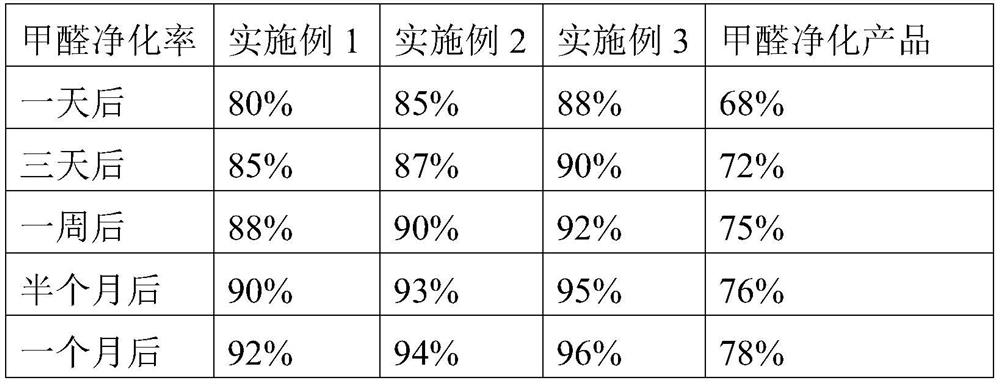

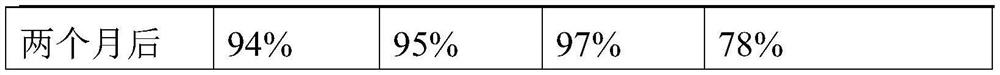

Examples

Embodiment 1

[0026] A microcapsule formaldehyde remover, which is composed of a core material and a wall material with a mass ratio of 1:3; the formaldehyde remover core material includes the following components in parts by weight: 5 parts of tea polyphenols, 2 parts of aloe extract, Chlorophytum 3 parts of extract, 2 parts of agave extract, 5 parts of nano-carbon black, 2 parts of nano-silver, 2 parts of grape seed oil, 1 part of lemongrass essential oil, 0.5 parts of lavender essential oil, 0.5 parts of eucalyptus essential oil, emulsifier 3 parts, 1.5 parts of co-emulsifier, 1 part of dispersant, 1 part of pH stabilizer; the wall material of formaldehyde remover is modified starch. Emulsifier is sorbitan fatty acid ester. Co-emulsifier is fatty acid diethanolamide.

[0027] A preparation method of microcapsule formaldehyde remover, comprising the following steps:

[0028] (1) Preparation of tea polyphenols: take 10 parts by weight of tea leaves, heat them in 100 parts of distilled wa...

Embodiment 2

[0040] A microcapsule formaldehyde remover, which is composed of a core material and a wall material with a mass ratio of 1:4; the formaldehyde remover core material includes the following components in parts by weight: 8 parts of tea polyphenols, 3 parts of aloe extract, Chlorophytum 4 parts of extract, 3 parts of agave extract, 8 parts of nano-carbon black, 3 parts of nano-silver, 3 parts of grape seed oil, 2 parts of lemongrass essential oil, 0.8 parts of lavender essential oil, 0.8 parts of eucalyptus essential oil, emulsifier 5 parts, 2 parts of co-emulsifier, 2 parts of dispersant, 1 part of PH stabilizer; the wall material of formaldehyde remover is modified starch. Emulsifier is sorbitan fatty acid ester. Co-emulsifier is fatty acid diethanolamide.

[0041]A preparation method of microcapsule formaldehyde remover, comprising the following steps:

[0042] (1) Preparation of tea polyphenols: take 15 parts by weight of tea leaves, heat them in 100 parts of distilled wat...

Embodiment 3

[0054] A microcapsule formaldehyde remover, which is composed of a core material and a wall material with a mass ratio of 1:6; the formaldehyde remover core material includes the following components in parts by weight: 10 parts of tea polyphenols, 5 parts of aloe extract, Chlorophytum 5 parts of extract, 4 parts of agave extract, 10 parts of nano-carbon black, 5 parts of nano-silver, 3 parts of grape seed oil, 2 parts of lemongrass essential oil, 1 part of lavender essential oil, 1 part of eucalyptus essential oil, emulsifier 10 parts, 3 parts of co-emulsifier, 3 parts of dispersant, 1 part of pH stabilizer; the wall material of formaldehyde remover is modified starch. Emulsifier is sorbitan fatty acid ester. Co-emulsifier is fatty acid diethanolamide.

[0055] A preparation method of microcapsule formaldehyde remover, comprising the following steps:

[0056] (1) Preparation of tea polyphenols: take 20 parts by weight of tea leaves, heat them in 100 parts of distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com