A kind of environmental protection nail polish and preparation method thereof

A nail polish, environmental protection technology, applied in the direction of manicure, pedicure, medicine formula, etc., can solve the problem of nail polish not resistant to erasure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A kind of preparation method of nail polish comprises the steps:

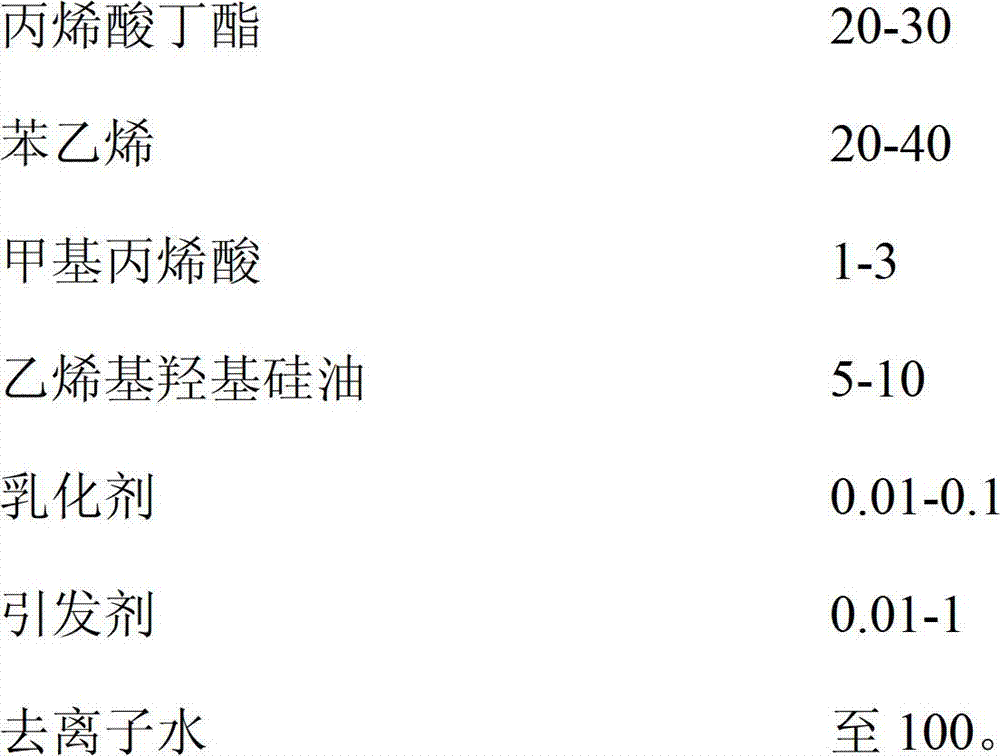

[0069] (1) Preparation of emulsion: Add formula amount of deionized water and 0.1g of emulsifier to the reactor, under stirring state, add initiator 0.01g and 1 / 3 of formula amount of emulsion to prepare monomer for seed polymerization Raise the temperature to 85°C, drop the remaining emulsion to prepare the monomer (guarantee that the drop is completed within 1.8 hours), keep the temperature for 2 hours after the drop is completed, and then cool down to obtain the emulsion; wherein, the amount of the emulsion to prepare the monomer is 20g of butyl acrylate, Styrene 40g, methacrylic acid 3g, vinyl hydroxy silicone oil 10g, deionized water 26.89g;

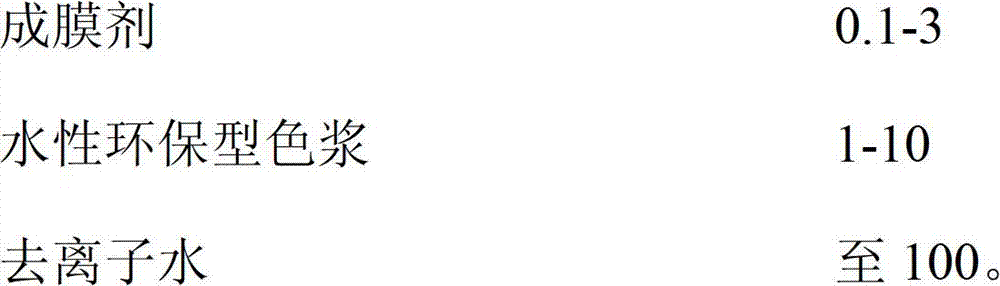

[0070] (2) Add 70g of the emulsion obtained in step (1) of the formula amount into the mixer for stirring, and at the same time add the formula amount of deionized water, film-forming agent, and leveling agent to the mixer in turn, continue stirring for 20 min...

Embodiment 2

[0072] A kind of preparation method of nail polish comprises the steps:

[0073] (1) Prepare the emulsion: add the formulated amount of deionized water and 0.01 g of the emulsifier into the reactor, and add 1 g of the initiator and 1 / 4 of the formulated amount of the emulsion into the reactor under stirring to prepare the monomer for seed polymerization; Raise the temperature to 75°C, drop the remaining emulsion to prepare the monomer (guarantee that the drop is completed within 2 hours), keep the temperature for 1.7 hours after the drop is completed, and then cool down to obtain the emulsion; among them, the amount of the emulsion preparation monomer is 25g of butyl acrylate, benzene Ethylene 30g, methacrylic acid 1g, vinyl hydroxy silicone oil 5g, deionized water 37.99g;

[0074] (2) Add 85g of the emulsion obtained in step (1) of the formula amount into the mixer for stirring, and at the same time add the formula amount of deionized water, film-forming agent, and leveling a...

Embodiment 3

[0076] A kind of preparation method of nail polish comprises the steps:

[0077] (1) Preparation of emulsion: Add formula amount of deionized water and 0.06g of emulsifier to the reactor, under stirring state, add initiator 1.3g and 1.1 / 4 formula amount of emulsion to prepare monomer for seed polymerization ;Raise the temperature to 90°C, drop the remaining emulsion to prepare the monomer (guarantee that the drop is completed within 1.9h), keep the temperature for 2.5h after the drop is completed, and then cool down to obtain the emulsion; the amount of the emulsion to prepare the monomer is 30g of butyl acrylate , styrene 20g, methacrylic acid 2.1g, vinyl hydroxy silicone oil 4.5g, deionized water 42.04g;

[0078] (2) Add 78.7g of the emulsion obtained in step (1) of the formula amount into the mixer for stirring, and at the same time add the formula amount of deionized water, film-forming agent, and leveling agent to the mixer in turn, continue stirring for 30 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com