Cinnamon extract taste-masking microcapsule and preparation method of microcapsule

A technology of cinnamon extract and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, food ingredients containing natural extracts, etc., can solve the problems of easy volatility, influence, and limited application, and achieve good taste masking and sustained release effects , Expand the scope of application, good taste masking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

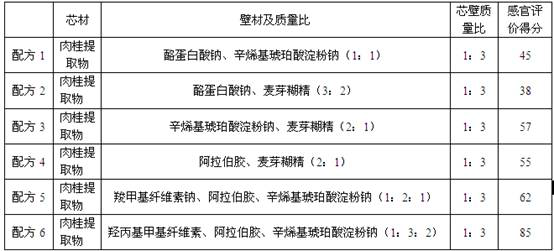

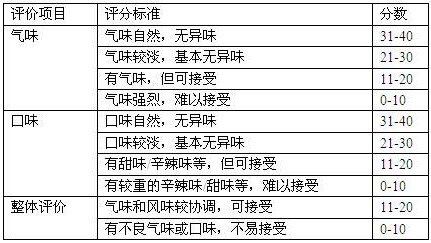

Examples

Embodiment 1

[0032] This embodiment provides a cinnamon extract taste-masking microcapsules, including emulsifier and the following substances in parts by weight: 10-20 parts of cinnamon extract, 5-10 parts of hydroxypropyl methylcellulose, octenyl succinate 5-15 parts of Sodium Starch Acid, 10-15 parts of Gum Arabic, and the percentage of the emulsifier in the sum of cinnamon extract, hydroxypropyl methylcellulose, sodium starch octenyl succinate and Gum Arabic weight is 0.1- 0.3%.

[0033] Microcapsule technology refers to the technology of using film-forming materials to encapsulate solids, liquids or gases in them to form tiny containers with a diameter of tens of microns to thousands of microns. It can protect substances from the influence of the environment, reduce toxicity, mask bad taste, control Capsule core release, prolong storage period, change physical properties and other functions. Therefore, microencapsulation of cinnamon extract can reduce its volatility, improve stabilit...

Embodiment 2

[0038] On the basis of Example 1, this example provides a cinnamon extract taste-masking microcapsules, including an emulsifier and the following materials in parts by weight: 10 g of cinnamon extract, 5 g of hydroxypropyl methylcellulose, octene starch sodium octenyl succinate 10g, gum arabic 15g, and the emulsifier accounts for 0.1-0.3% of the weight of cinnamon extract, hydroxypropyl methylcellulose, sodium starch octenyl succinate and gum arabic.

[0039] In this embodiment, the emulsifier is sodium stearoyl lactylate, added in an amount of 0.04 g, accounting for 0.1% of the mass and percentage of the core and wall materials. Sodium stearoyl lactylate has good emulsifying effect, less dosage and low price.

[0040] Preparation Process:

[0041] Heat 10 g of cinnamon extract to 80° C., add 0.04 g of sodium stearoyl lactylate, dissolve after stirring, and obtain a core material. Disperse 5g of hydroxypropyl methylcellulose in 150mL of hot water at a temperature of 75-85°C,...

Embodiment 3

[0061] On the basis of Example 1, this example provides a cinnamon extract taste-masking microcapsules, including an emulsifier and the following materials in parts by weight: 20 g of cinnamon extract, 5 g of hydroxypropyl methylcellulose, octene 10 g of sodium starch succinate, 15 g of gum arabic, and the percentage of the emulsifier to the weight of cinnamon extract, hydroxypropyl methylcellulose, sodium starch octenyl succinate and gum arabic is 0.1-0.3%.

[0062] In this embodiment, the emulsifier is sodium stearoyl lactylate, added in an amount of 0.12 g, accounting for 0.24% of the mass and percentage of the core and wall materials.

[0063] Preparation Process:

[0064] Heat 20 g of cinnamon extract to 100° C., add 0.12 g of sodium stearoyl lactylate, and stir to dissolve it. A core phase is produced. Disperse 5g of hydroxypropyl methylcellulose in 150mL of hot water at a temperature of 75-85°C, then add 150mL of cold water (at room temperature) and stir to fully diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com