Proportional Feed Mixing Equipment for Construction Engineering

A technology of construction engineering and mixing equipment, which is applied in the direction of mixers, mixers with rotating stirring devices, chemical/physical processes, etc., can solve the problems that slag is easily collided and crushed into slag chips, less slag, and slag is slag chips, etc. To achieve the effect of preventing uneven mixing, uniform feeding and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

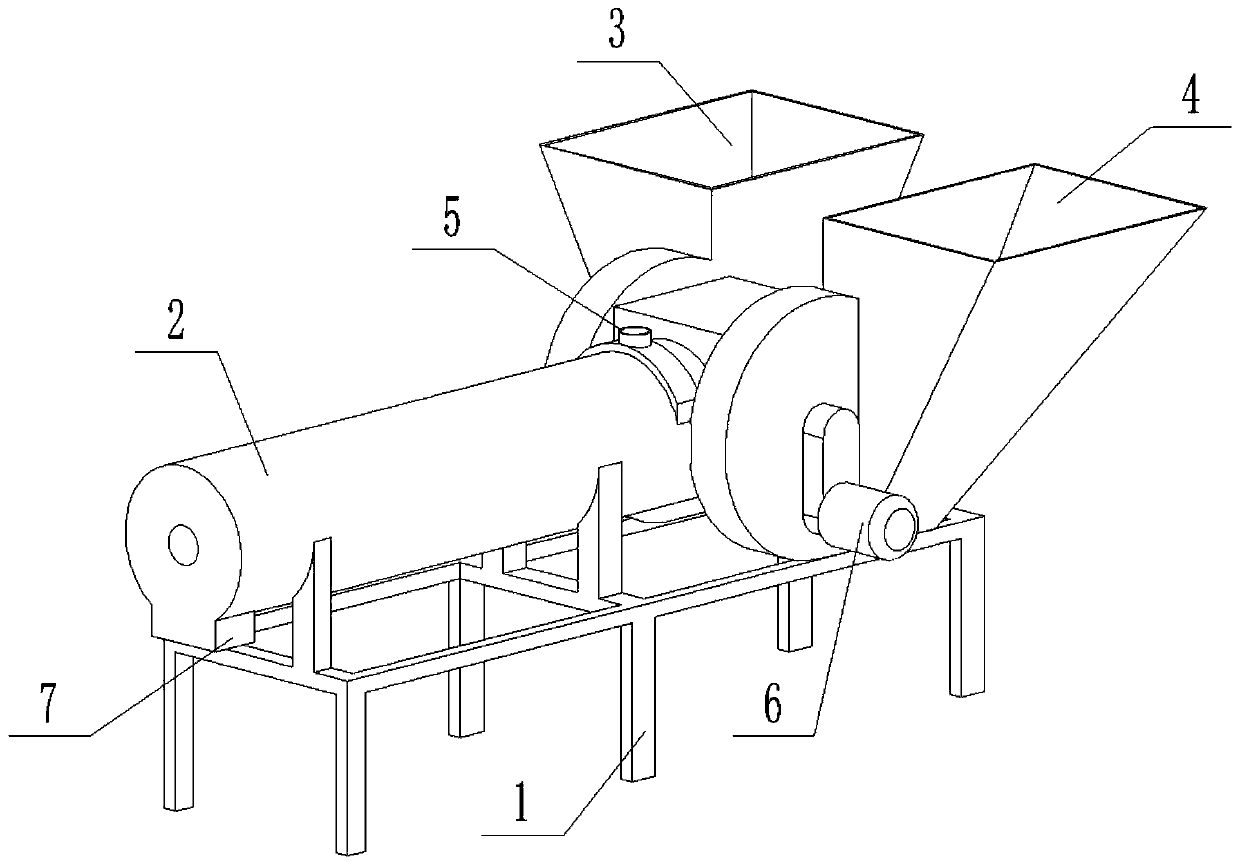

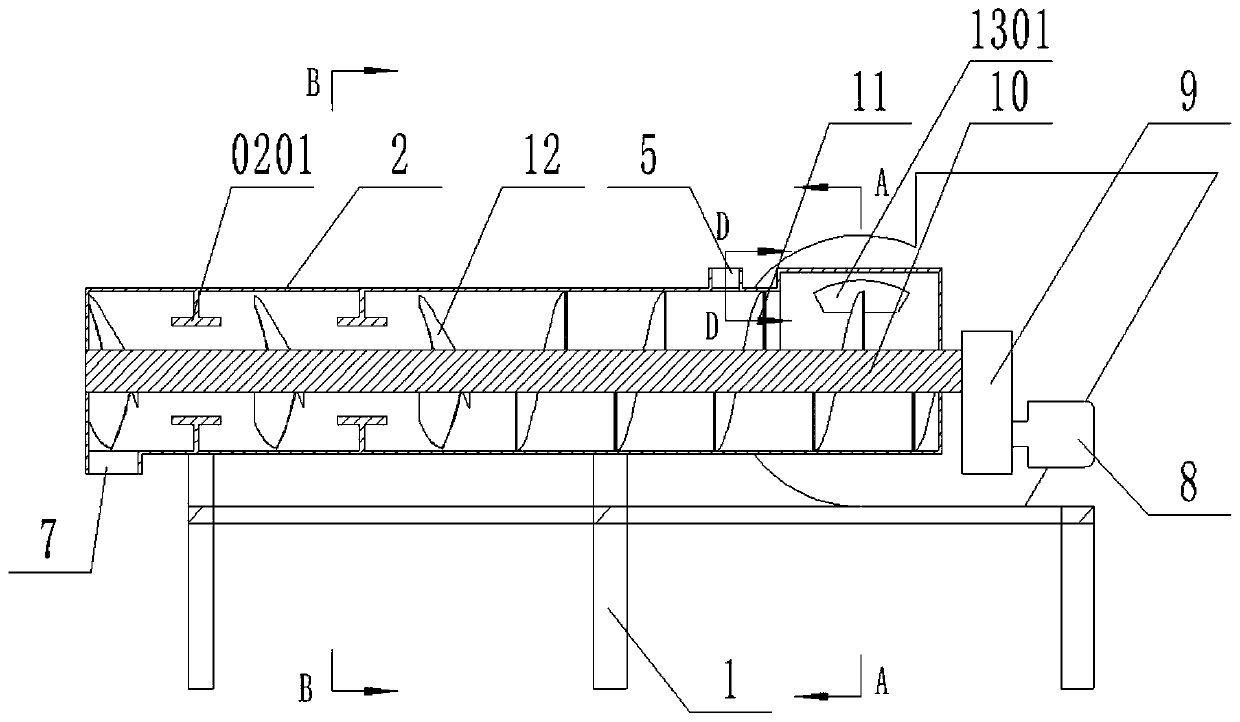

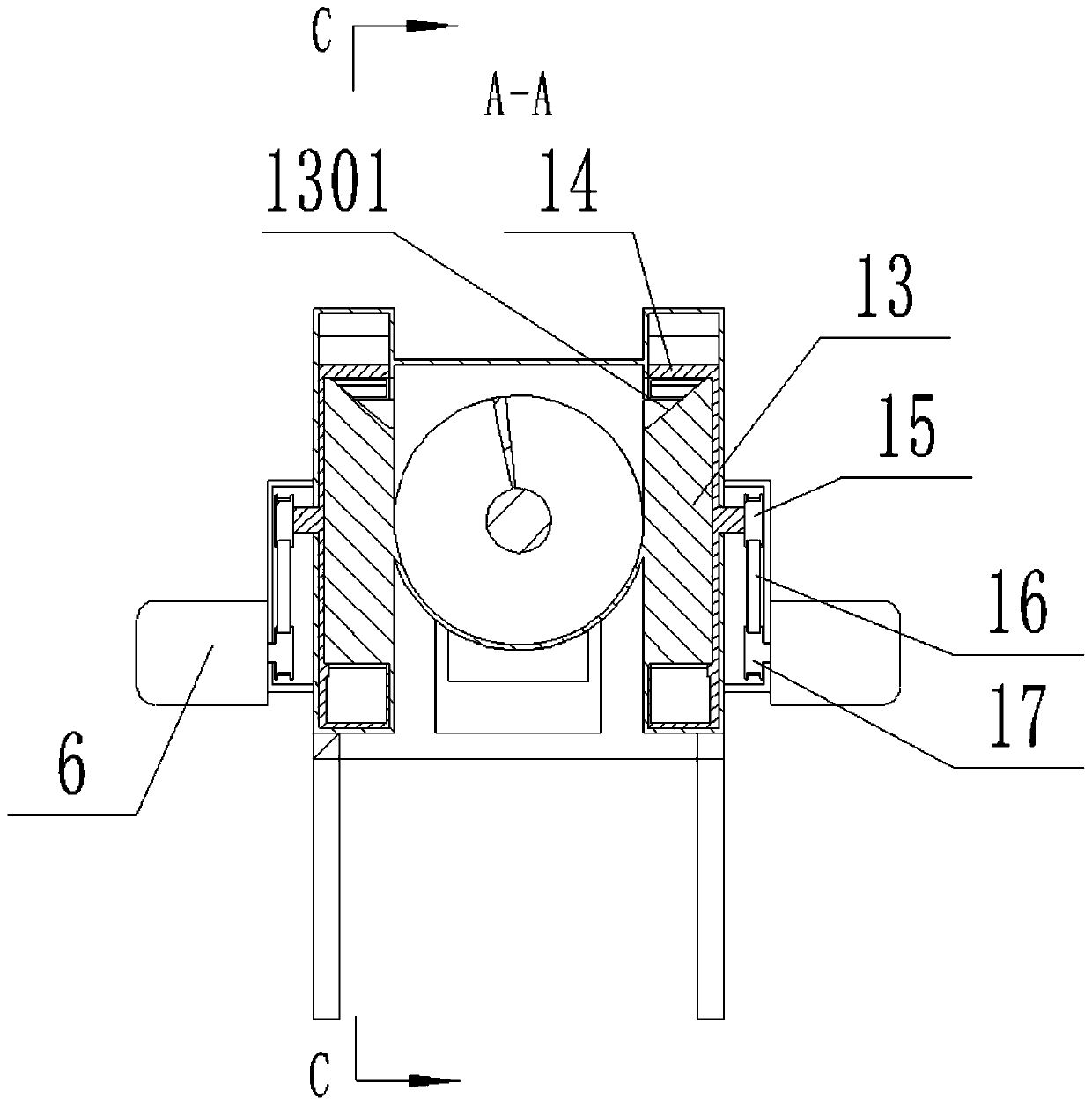

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides proportional feed mixing equipment for construction engineering, including: a base 1, a mixing tank 2, a fixed mixing paddle 0201, a first material bin 3, a second material bin 4, a first water inlet 5, a feeding Motor 6, mixing material outlet 7, mixing motor 8, gearbox 9, stirring shaft 10, screw propulsion blade 11, mixing blade 12, baffle plate 13, feeding trough 1301, retrieving wheel 14, retrieving hopper 1401, discharging Hole 1402, driven pulley 15, transmission belt 16, driving pulley 17, water equalizing plate 18 and second water inlet 1801; base 1 top is fixedly connected with a group of mixing buckets 2; the inner central axis of mixing bucket 2 is connected with a A group of stirring shafts 10; the right end face of the mixing barrel 2 is fixedly connected with a group of gearboxes 9; the power input shaft of the gearbox 9 is fixedly connected with a group of hybrid mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com