A kind of silver alloy solder paste with good dispensing performance and preparation method thereof

A silver alloy welding, silver alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools and other directions, can solve the problems of poor continuous dispensing performance, unstable product performance, short service life of silver alloy solder paste, etc. Improve the fluxing effect, increase the flux activity, and solve the effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

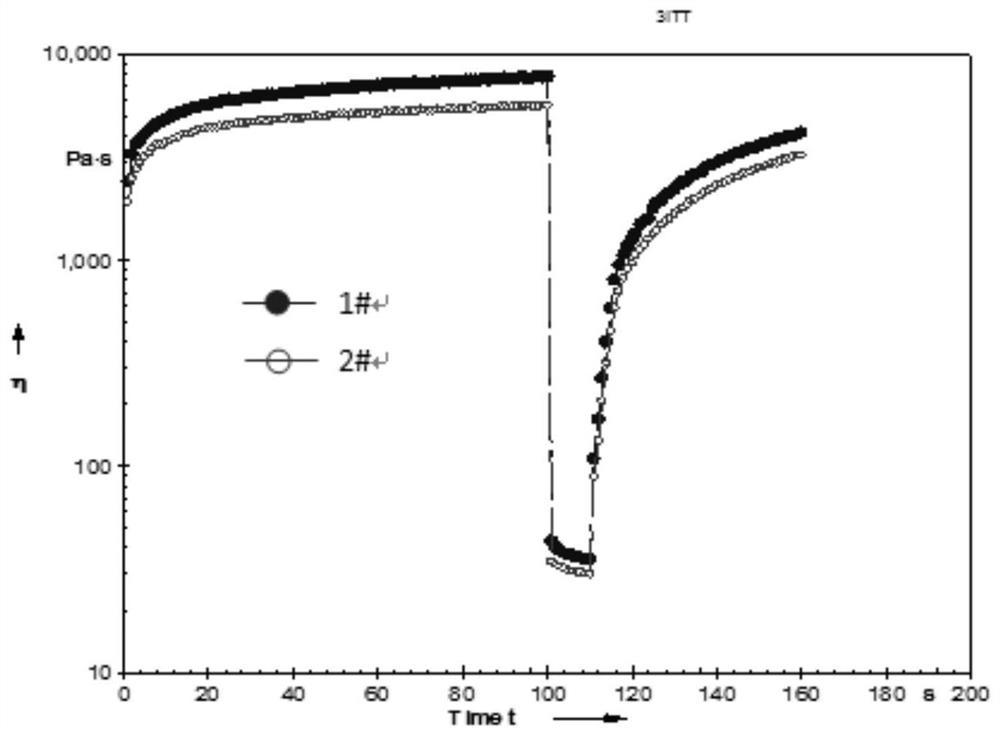

Embodiment 1

[0051] According to the weight percentage of the total solder paste, first add 15% organic solvent and 4% acrylic resin into a polytetrafluoroethylene jar, and rotate for 180min at a constant temperature of 120°C and a speed of 1400 rpm to obtain a uniform and stable solder paste. For polyacrylic acid resin solution, measure the solid content of the resin solution under the condition of 120°C / 1h, and add the lost organic solvent in proportion. Add 1.5% polyamide wax into the polyacrylic acid resin solution, stir for 20 minutes in a constant temperature oil bath at 55°C (≤70°C) and a stirring speed of 1000 rpm, so that the thixotropic agent is evenly distributed in the swollen state In the resin solution, measure the solid content of the organic carrier, and add the lost organic solvent in proportion. Then 68Wt.% sieved silver alloy powder (20Wt.% of particle size at -300 mesh, 60Wt.% of particle size at -200 mesh + 300 mesh, 20Wt.% of particle size at -100 mesh + 200 mesh) Ad...

Embodiment 2

[0053] According to the weight percentage of the total solder paste, first add 20% organic solvent and 3% rosin resin into a polytetrafluoroethylene jar, and rotate for 180min at a constant temperature of 120°C and a speed of 1400 rpm to obtain a uniform and stable resin solution, measure the solid content of the resin solution under the condition of 120°C / 1h, and add the lost organic solvent in proportion. Add 1% hydrogenated castor oil to the rosin resin solution, stir for 20 minutes in a constant temperature oil bath at 55°C (≤70°C) and a stirring speed of 1000 rpm, so that the thixotropic agent is evenly distributed in the resin in a swollen state In the solution, measure the solid content of the organic carrier, and add the lost organic solvent in proportion. Then 60Wt.% silver alloy powder (15Wt.% of particle size at -300 mesh, 65Wt.% of particle size at -200 mesh + 300 mesh, 20Wt.% of particle size at -100 mesh + 200 mesh) by mass ratio 4:6 is added in two times, and t...

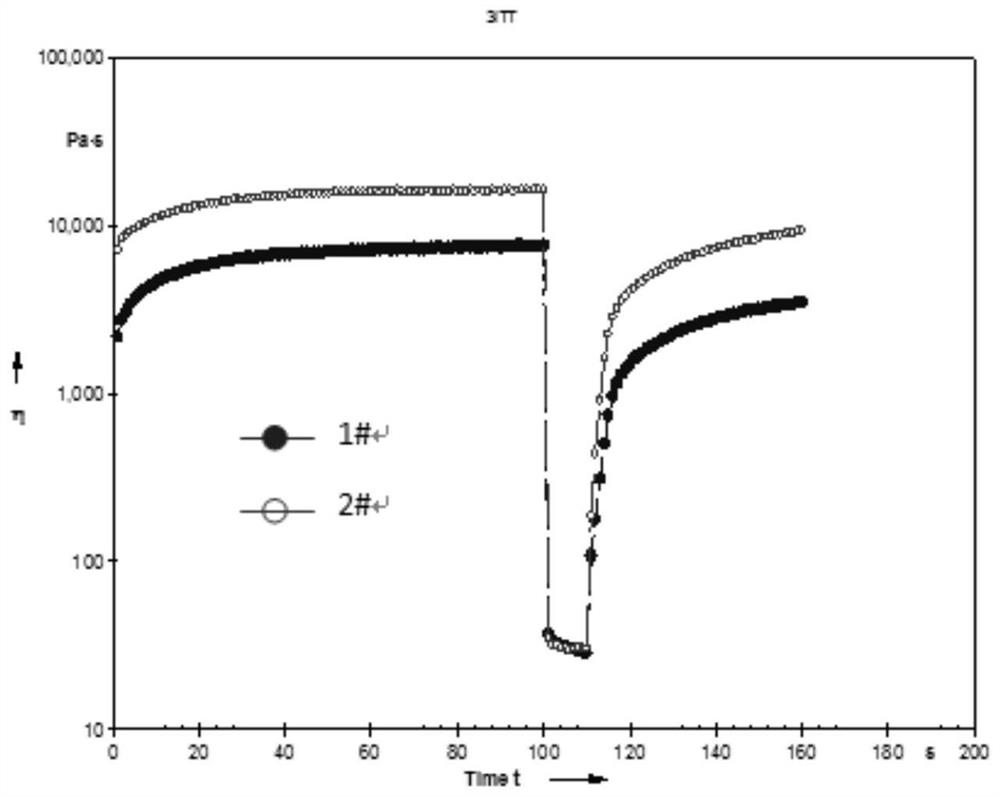

Embodiment 3

[0055] According to the weight percentage of the total solder paste, first add 20% organic solvent and 3% acrylic resin into a polytetrafluoroethylene jar, and rotate for 180min at a constant temperature of 120°C and a speed of 1400 rpm to obtain a uniform and stable resin solution, measure the solid content of the resin solution under the condition of 120°C / 1h, and add the lost organic solvent in proportion. Add 1% polyamide wax to the acrylic resin solution, and stir for 20 minutes in a constant temperature oil bath at 55°C (≤70°C) with a stirring speed of 1000 rpm, so that the thixotropic agent is evenly distributed in the resin in a swollen state In the solution, measure the solid content of the organic carrier, and add the lost organic solvent in proportion. Then 60Wt.% silver alloy powder (15Wt.% of particle size at -300 mesh, 65Wt.% of particle size at -200 mesh + 300 mesh, 20Wt.% of particle size at -100 mesh + 200 mesh) by mass ratio 4:6 is added in two times, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com