Crystalline silicon solar cell screen for positive electrode hollow molding

A solar cell and positive electrode technology, applied in printing plates, circuits, photovoltaic power generation, etc., can solve the problem of unsatisfactory broken grid ratio, achieve the effects of increasing hot spot effect, wide application range, and simple screen structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

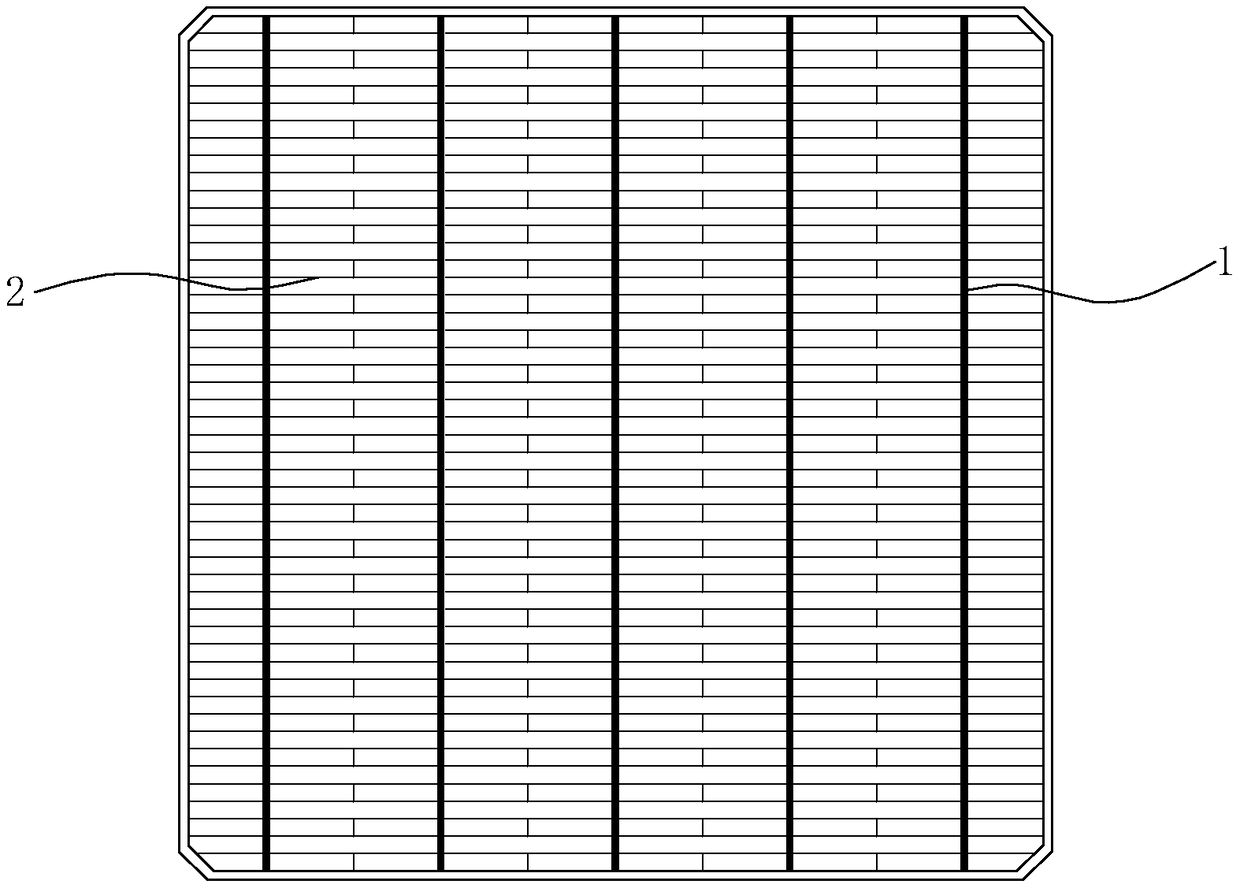

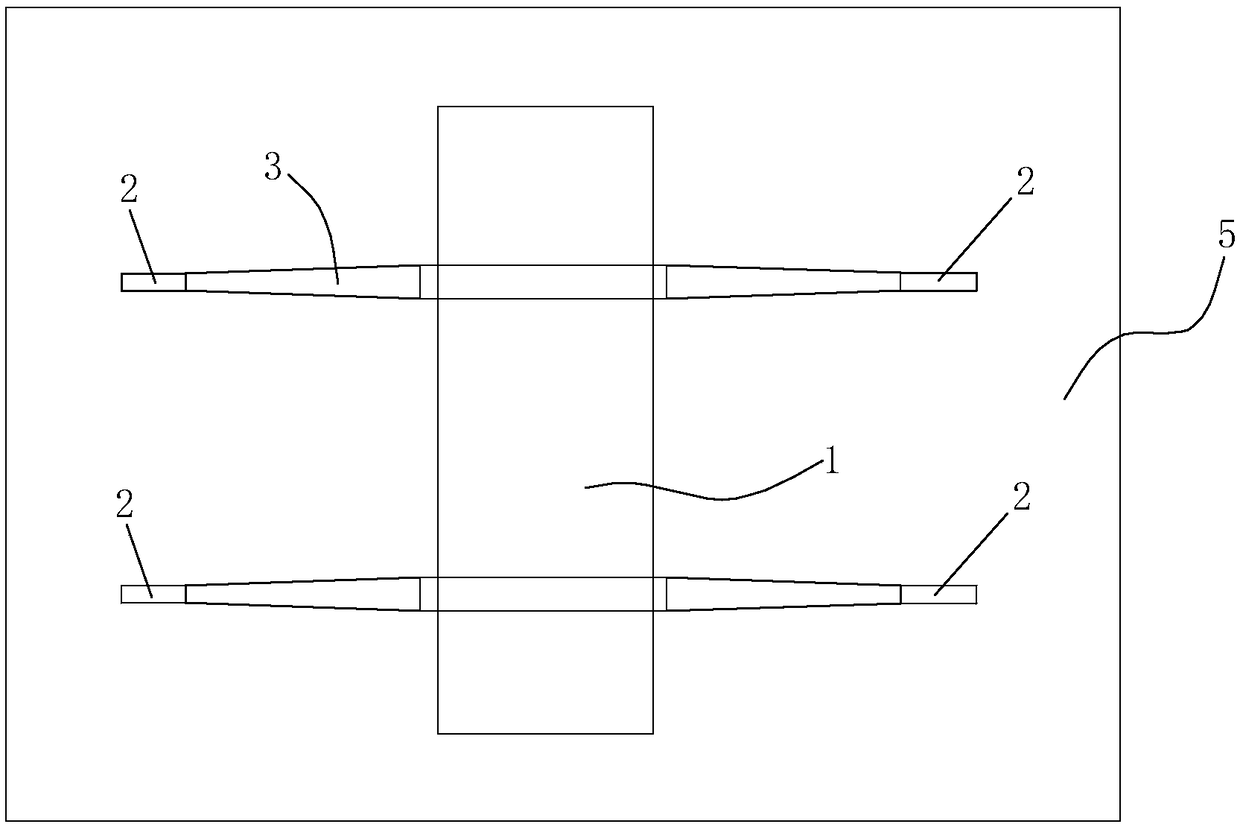

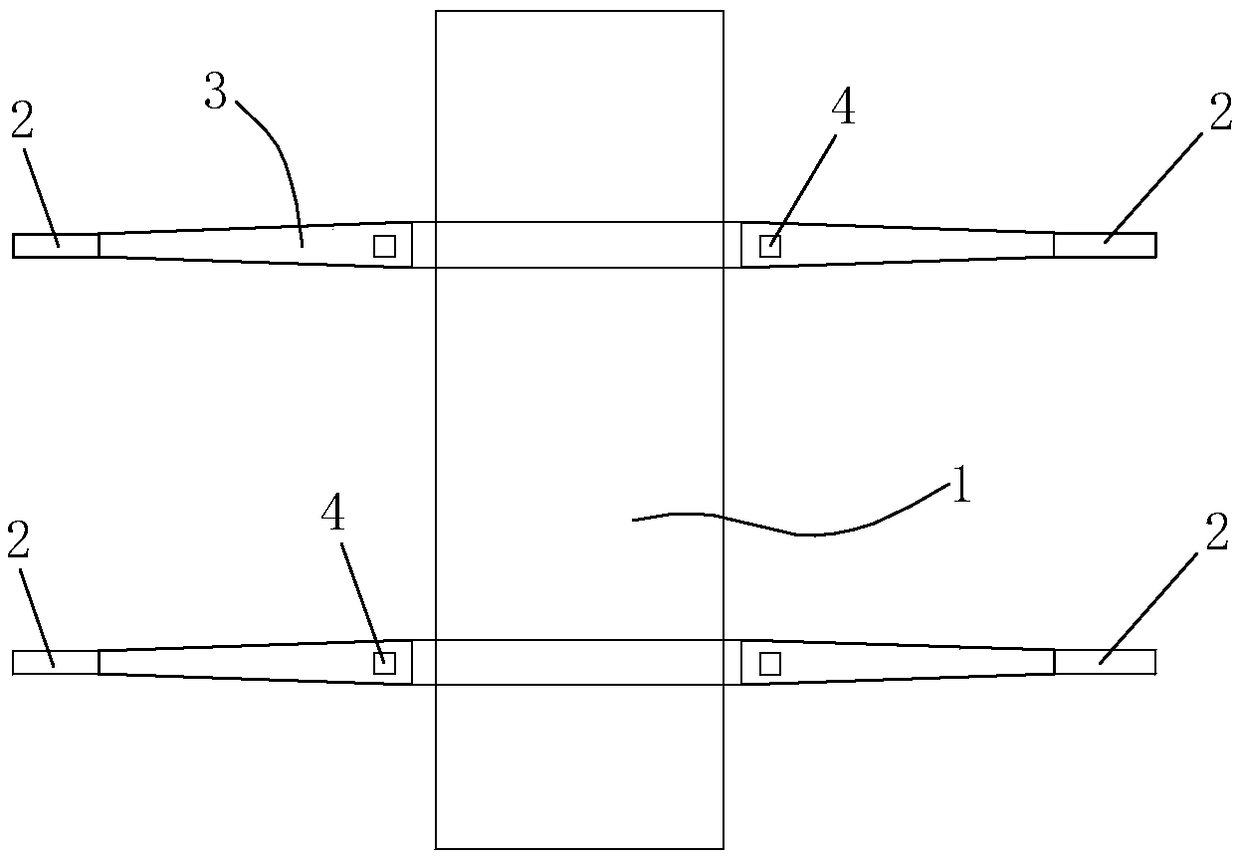

[0023] Such as Figure 1 to Figure 6 The crystalline silicon solar cell screen plate used for positive electrode hollow forming is shown. The positive electrode of the crystalline silicon solar cell includes the positive electrode main grid 1, the positive electrode fine grid 2 and the anti-broken grid structure 3, the anti-broken grid structure 3 and the positive electrode The fine grid 2 is integrally printed and formed, and the printed anti-broken grid structure 3 and the positive electrode fine grid 2 form a line, both of which are perpendicular to the positive electrode main grid 1. The anti-broken grid structure 3 is octagonal, and the anti-broken grid structure 3 is located on the The rectangular grid section in the middle is composed of two isosceles trapezoidal grid sections located on both sides of the rectangular grid section and arranged symmetrically with the rectangular grid section as the center. A reduced grid section in which the section of the grid 2 graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com