Power battery mounting structure of a new energy commercial vehicle

A technology of power battery and installation structure, which is applied to power units, electric power units, structural parts, etc., can solve the problems of difficult alignment of bolt mounting holes, inconvenient replacement of power batteries, and low production efficiency of the whole vehicle. The effect of moving and installing less time and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

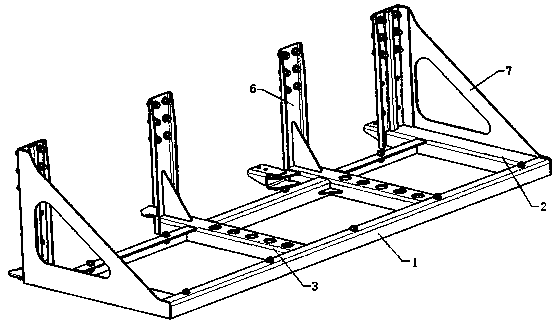

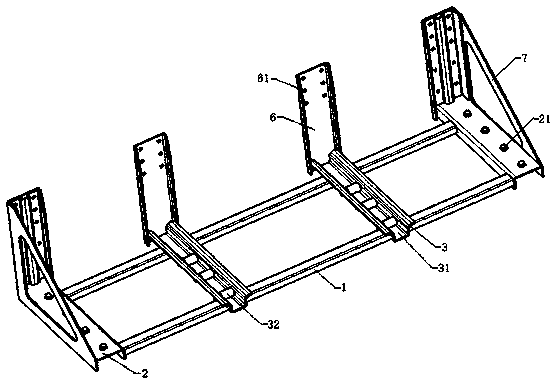

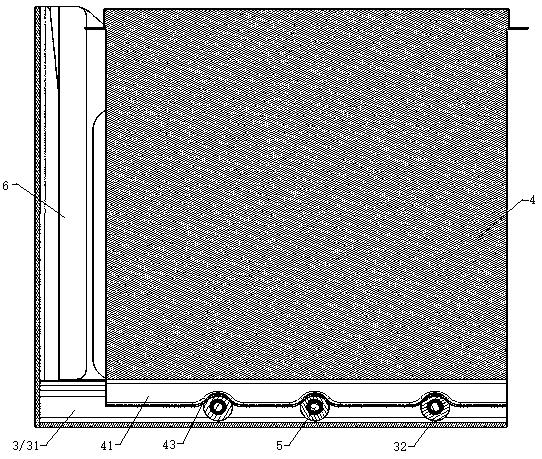

[0029] Such as Figure 2 to Figure 5 As shown, the present invention provides a new energy commercial vehicle power battery installation structure, which includes a frame body beam 1 fixedly connected, a frame body longitudinal beam 2 and an intermediate longitudinal beam 3, wherein the intermediate longitudinal beams 3 are arranged in parallel Between the two frame longitudinal beams 2, the frame body beam 1, the frame body longitudinal beam 2 and the intermediate longitudinal beam 3 are vertically arranged; the intermediate longitudinal beam 3 is provided with a groove 31, and the groove 31 is provided with a number of rollers 32 at fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com