Annular wavy periodic floating raft

A wavy and annular technology, applied in the direction of ships, hull parts, hulls, etc., can solve the problems of cumbersome preparation requirements and steps, lack of circumferential symmetry, excessive structural deformation, etc. Effects of optimization of bending, mass and stiffness parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

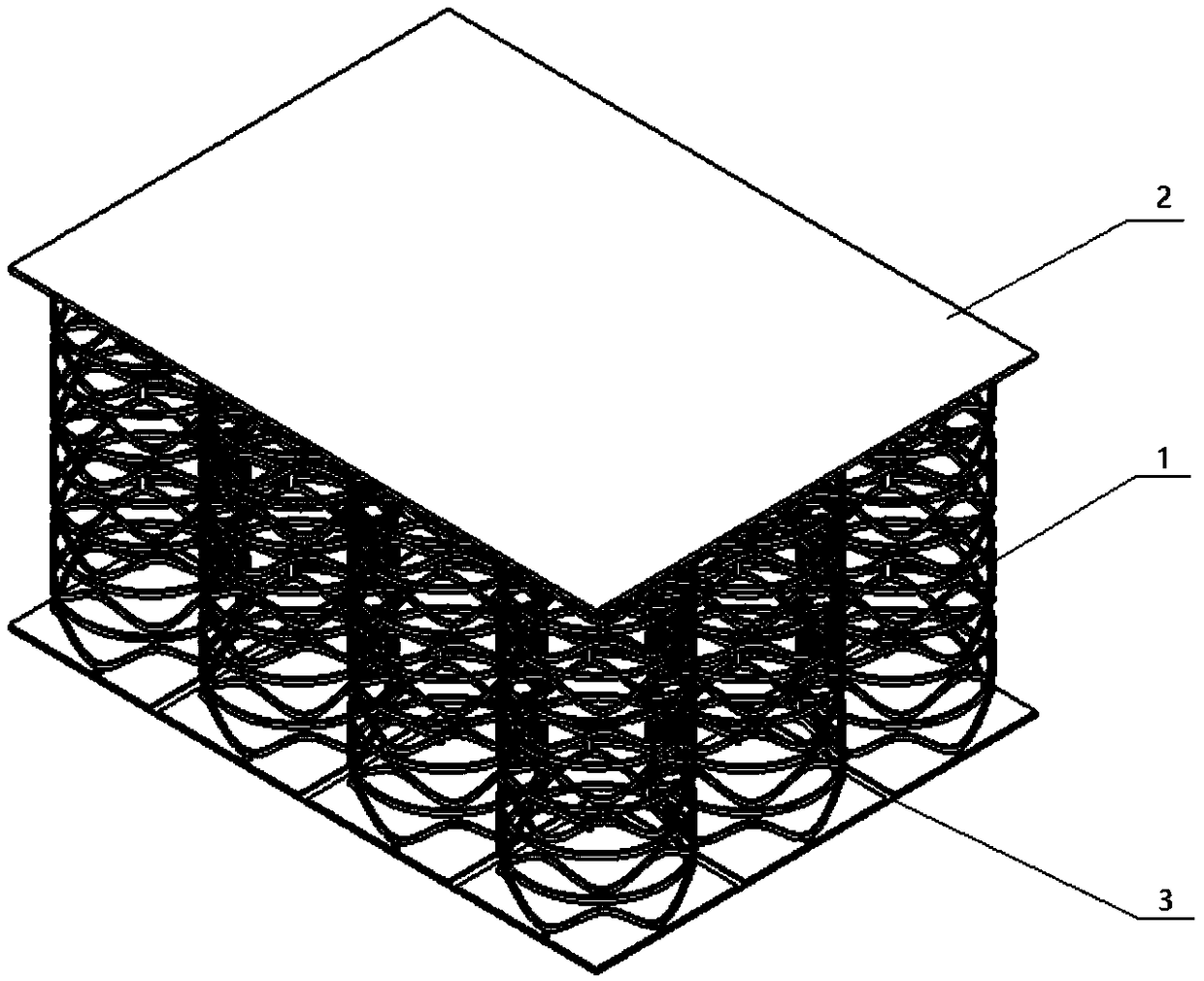

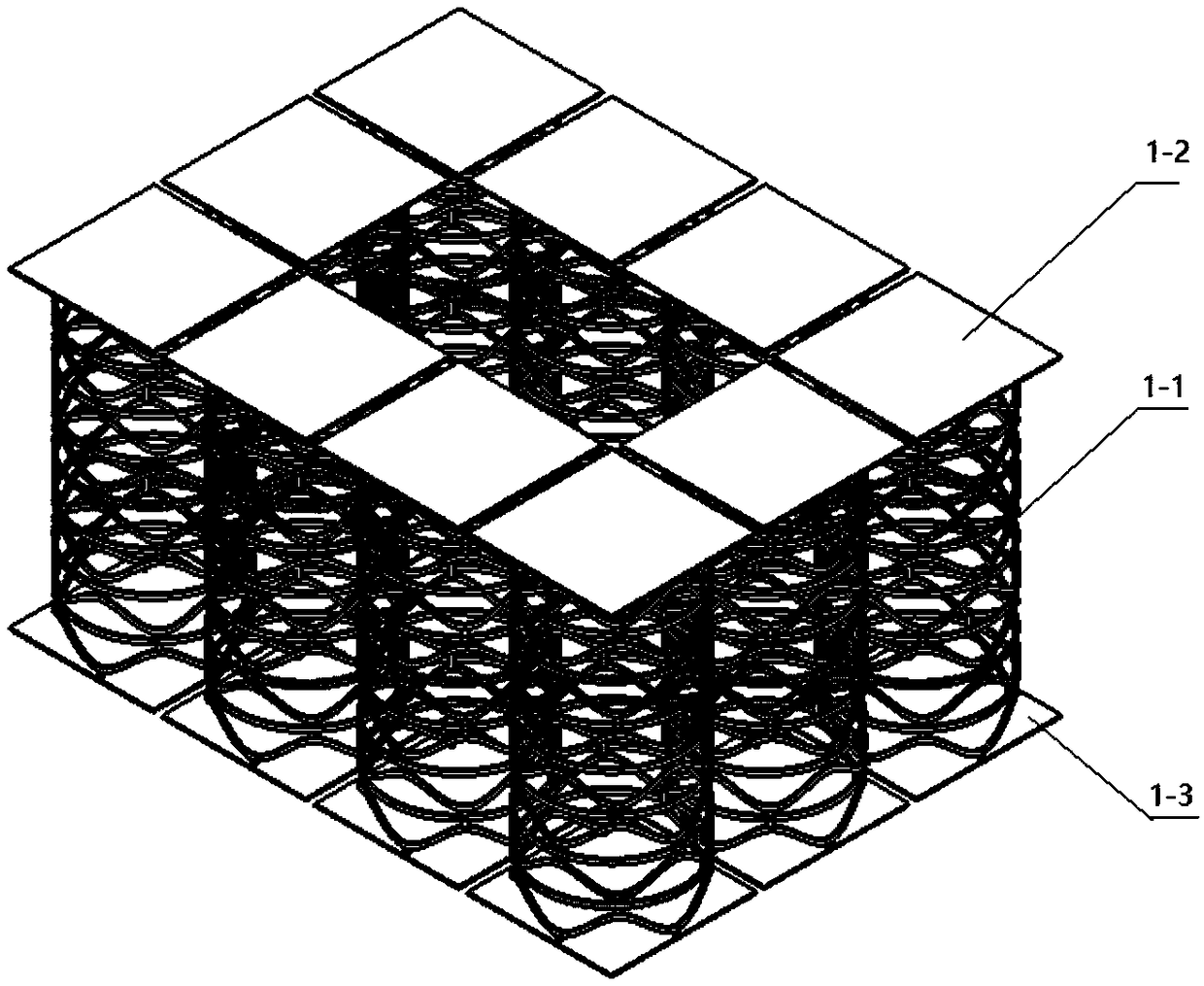

[0034] Such as Figure 1~5 As shown, it is a kind of ring-shaped wave-shaped periodic floating raft of the present invention, which is composed of 10 ring-shaped wave-shaped periodic structural parts 1, upper panel 2 and lower panel 3 (such as figure 1 shown), wherein the ring-shaped wave-shaped periodic structural members 1 are arranged in the shape of a "mouth" in the horizontal direction (such as figure 2 shown).

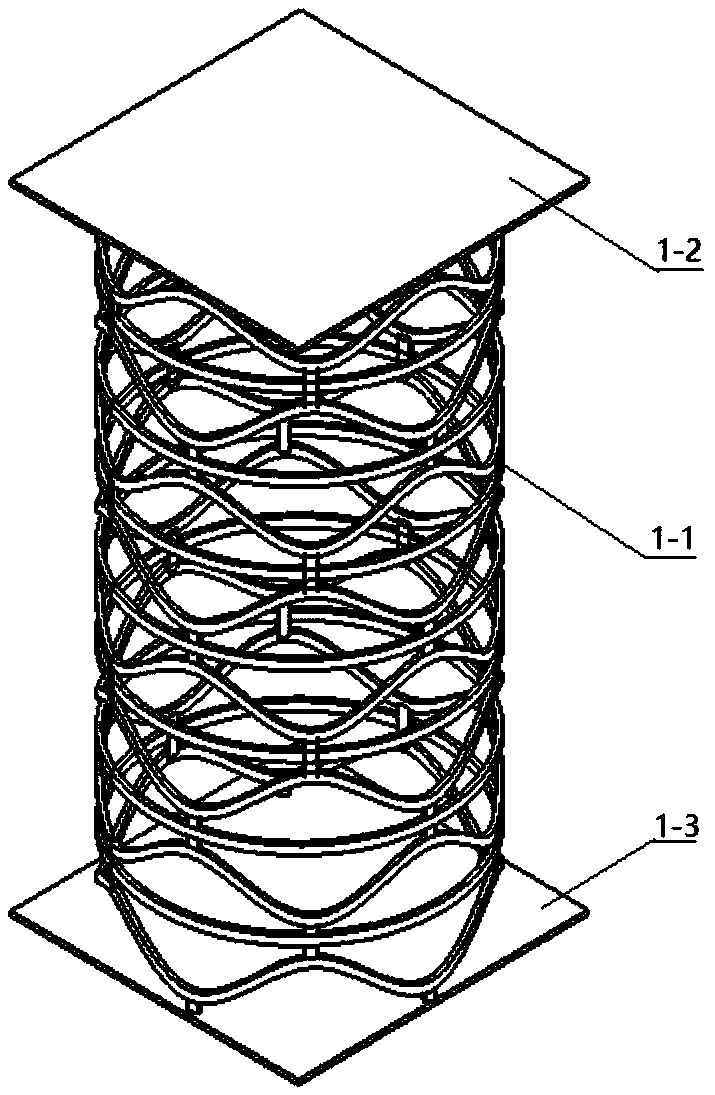

[0035] The ring-shaped wave-shaped periodic structure 1 is composed of an ring-shaped wave-shaped structure 1-1, an upper small panel 1-2, and a lower floor small panel 1-3 (such as image 3 shown).

[0036] The ring-shaped wave-shaped structural member 1-1 is composed of multi-layer wave rings 1-1-1 superimposed in the vertical direction, and two wave rings 1-1-1 are connected in mirror images, and connecting blocks 1-1-1 are arranged at the joints. 1-2, a stabilizing ring 1-1-3 is arranged between two wave rings to increase the circumferential rigidity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com