A kind of micron silicate spherical phosphor and preparation method thereof

A phosphor and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of polluted powder, incomplete reaction, complicated preparation process, etc., achieve excellent durability and weather resistance, and facilitate industrial production. , luminous colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

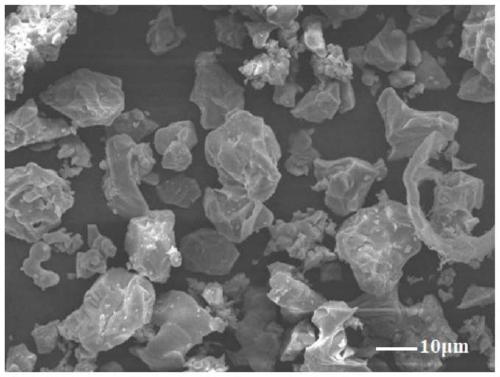

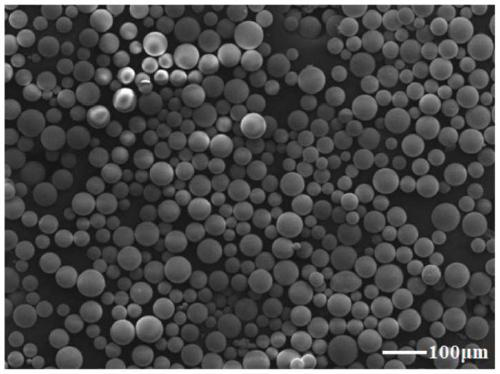

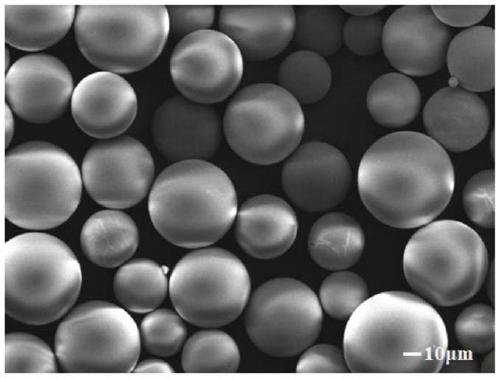

[0035] This embodiment provides a method for preparing a micron-sized silicate spherical phosphor, specifically providing a micron-sized Ca 3 Y 1.9 Si 3 o 12 :0.1Eu 3+ The preparation method of red spherical fluorescent powder comprises the following steps:

[0036] S1, with CaCO 3 , Y 2 o 3 , SiO 2 and Eu 2 o 3 As a raw material, the original fluorescent powder is prepared by a high-temperature solid phase method.

[0037] Specifically, step S1 includes the following sub-steps:

[0038] S11, take by weighing 25.5877g analytically pure (99.9%) CaCO respectively 3 , 18.4739g high-purity (99.99%) Y 2 o 3 , 1.5153g high-purity (99.99%) Eu 2 o 3 and 15.5229 g of analytically pure (99.9%) SiO 2 . Among them, CaCO 3 , Y 2 o 3 and SiO 2 Mainly used as a reactant for the synthesis of phosphors, Eu 2 o 3 It is mainly used as the activator raw material of phosphor powder.

[0039] S12. Mix all the raw materials weighed in step S11 together for grinding to form a ...

Embodiment 2

[0062] This embodiment provides a method for preparing a micron-sized silicate spherical phosphor, specifically providing a micron-sized Ca 3 Gd 1.9 Si 3 o 12 :0.1Eu 3+ The preparation method of red spherical fluorescent powder comprises the following steps:

[0063] S1, with CaCO 3 、Gd 2 o 3 , SiO 2 and Eu 2 o 3 As a raw material, the original fluorescent powder is prepared by a high-temperature solid phase method. Specifically, step S1 includes the following sub-steps:

[0064] S11. According to the stoichiometric ratio, weigh CaCO 3 、Gd 2 o 3 、Eu 2 o 3 and SiO 2 .

[0065] S12. Mix all the raw materials weighed in step S11 together for grinding to form a mixed material. Specifically, ball milling is used for grinding, and all the raw materials weighed are put into a ball mill jar, and ZrO is added at the same time 2 Grinding balls, anhydrous ethanol and ammonium polyacrylate, carry out wet mixing, the ball milling time is 6h, and the rotation speed is 100...

Embodiment 3

[0073] This embodiment provides a method for preparing a micron-sized silicate spherical phosphor, specifically providing a micron-sized Ca 3 Lu 1.9 Si 3 o 12 :0.1Eu 3+ The preparation method of red spherical fluorescent powder comprises the following steps:

[0074] S1, with CaCO 3 、Lu 2 o 3 , SiO 2 and Eu 2 o 3 As a raw material, the original fluorescent powder is prepared by a high-temperature solid phase method. Specifically, step S1 includes the following sub-steps:

[0075] S11. According to the stoichiometric ratio, weigh CaCO 3 、Lu 2 o 3 、Eu 2 o 3 and SiO 2 .

[0076] S12. Mix all the raw materials weighed in step S11 together for grinding to form a mixed material. Specifically, ball milling is used for grinding, and all the raw materials weighed are put into a ball mill jar, and ZrO is added at the same time 2 Grinding balls, absolute ethanol and ammonium polyacrylate are used for wet mixing, the ball milling time is 6 hours, and the rotation speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com