Thermal spraying method and system based on artificial intelligence

A technology of artificial intelligence and thermal spraying, which is applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of heavy workload, cumbersome work, poor effect, etc., to improve work efficiency, reduce time, Good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

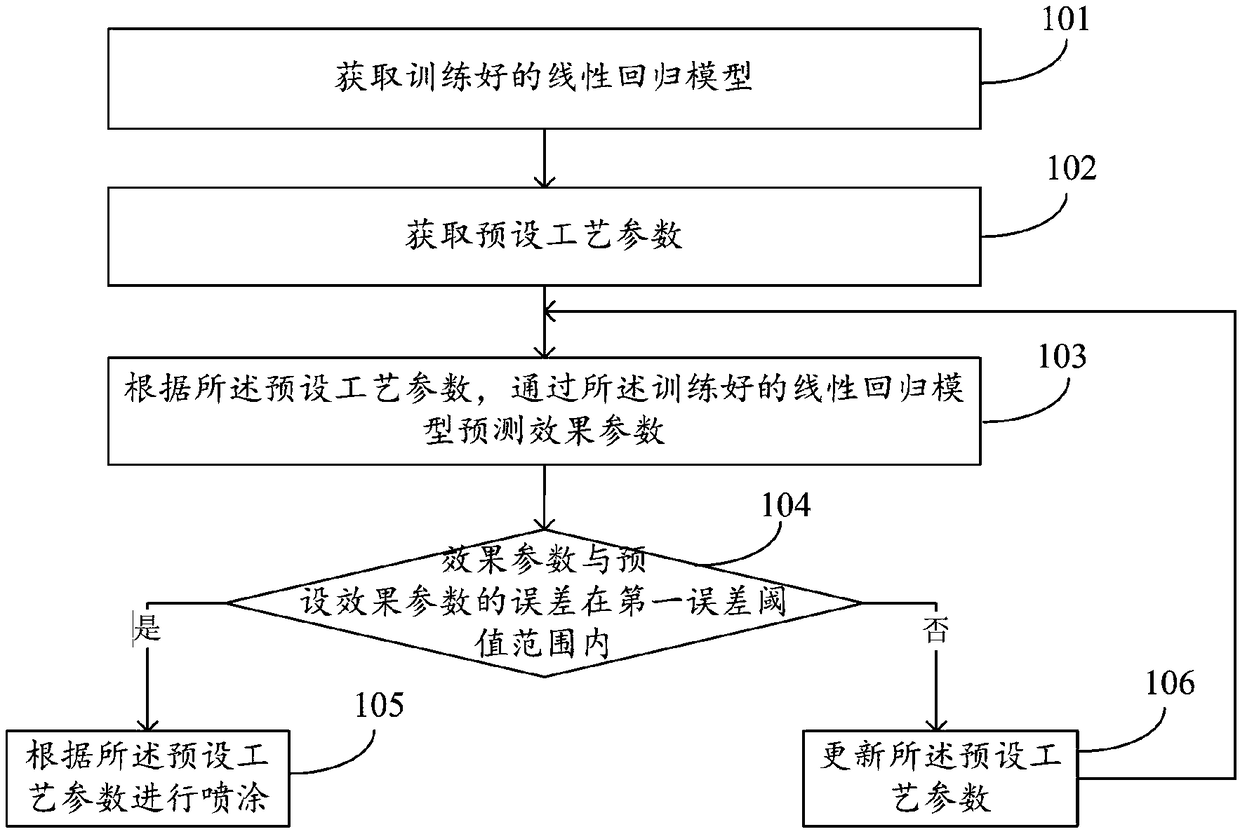

[0046] Example 1, such as figure 1 As shown, an artificial intelligence-based thermal spraying method includes the following steps:

[0047] Step 101: Obtain a trained linear regression model.

[0048] Step 102: Obtain preset process parameters; the process parameters are parameters reflecting the technical indicators of the thermal spraying process; the preset process parameters include: the current size of the spraying equipment, the flow rate of helium, the flow rate of argon, and the flow rate of the carrier gas , turntable angle, powder feeding needle angle and powder feeding distance.

[0049] The current size, helium flow rate, argon flow rate, carrier gas flow rate, turntable angle, powder feeding needle angle and powder feeding distance of the spraying equipment for thermal spraying of metal powder are the technical indicators reflecting the spraying process of thermal spraying parameter. Current is a process parameter on the device for controlling thermal spraying...

Embodiment 2

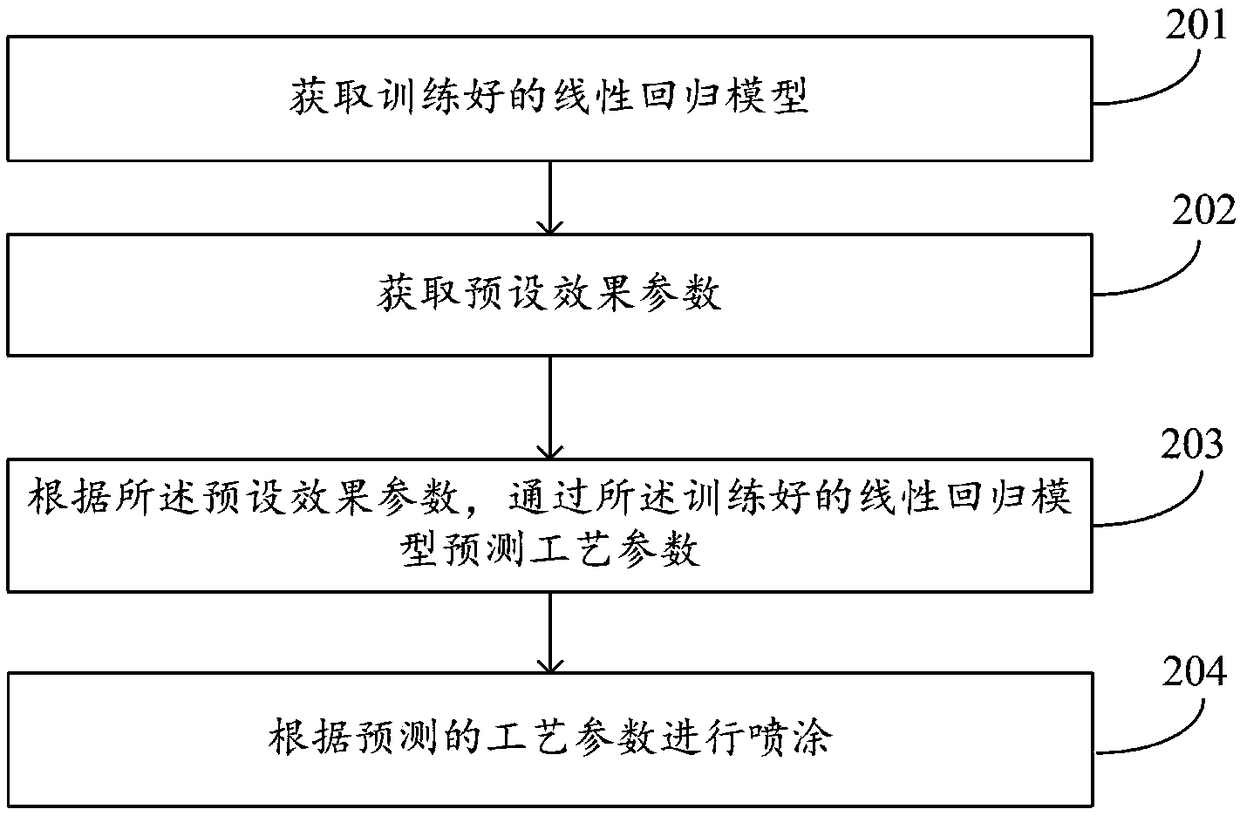

[0059] Example 2, such as figure 2 As shown, an artificial intelligence-based thermal spraying method includes the following steps:

[0060] Step 201: Obtain a trained linear regression model.

[0061] Step 202: Obtain preset effect parameters; the effect parameters are parameters reflecting the technical indicators of the spraying effect; the effect parameters include bonding strength, porosity, metallography and hardness.

[0062] Step 203: According to the preset effect parameters, predict the process parameters through the trained linear regression model; the process parameters are parameters reflecting the technical indicators of the thermal spraying process; the preset process parameters include: spraying equipment Current size, helium flow, argon flow, carrier gas flow, turntable angle, powder feeding needle angle and powder feeding distance.

[0063] Step 204: Spraying according to the predicted process parameters.

[0064] Also include before step 201:

[0065] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com