Water-sealing anti-slip and anti-crack sticker of a precast asphalt pavement and a construction process thereof

A technology of asphalt pavement and construction technology, which is applied in the field of asphalt pavement paving, and can solve the problems of long construction period, water seepage and mud pumping on the pavement, and achieve simple pavement construction and repair procedures, strong waterproof ability and waterproof ability, and reduce traffic the effect of the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

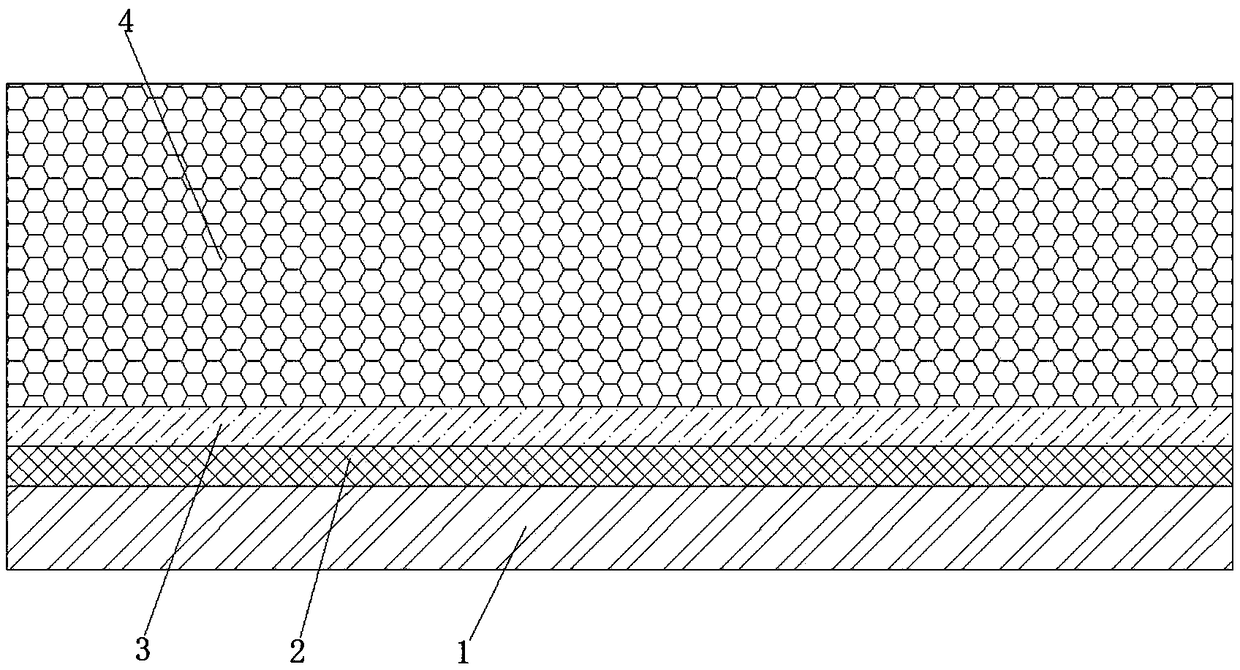

[0023] refer to figure 1 , a prefabricated asphalt pavement sealing water anti-slip anti-cracking paste, its structure has three layers, from top to bottom are a layer of anti-slip layer 1, a layer of waterproof adhesive layer 2 and a layer of geotextile 3.

[0024] The anti-skid layer 1 is composed of a certain proportion of SBS modified asphalt and 5-10mm wear-resistant aggregate, which is placed on the waterproof bonding layer 2;

[0025] The waterproof bonding layer 2 is placed between the thin anti-skid layer 1 and the geotextile 3 for waterproofing and bonding the thin anti-skid layer 1 and the geotextile 3;

[0026] The geotextile 3, whose composition is ECB,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com