Steel structure external wall thermal insulation mortar enclosure system with pulling element and construction process thereof

A technology for external wall thermal insulation and enclosure systems, applied in thermal insulation, building components, building structures, etc., can solve problems such as weakened thermal insulation function, poor bonding, hollowing, etc., and achieve high-quality thermal insulation performance, good The effect of simple safety guarantee and construction process principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

[0039] The orientations described in the present application, such as up, down, left, and right, are used for the convenience of describing with reference to the accompanying drawings, and do not constitute a limitation on the scope of protection.

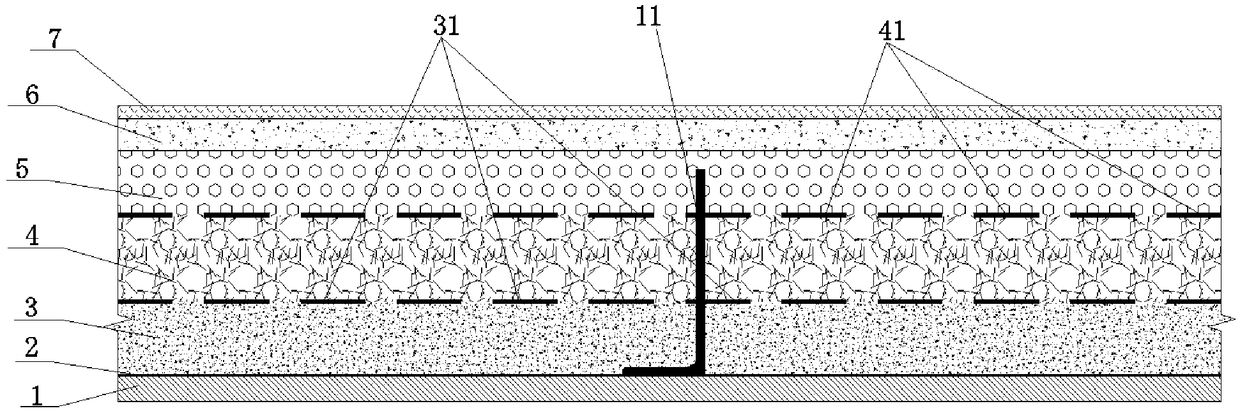

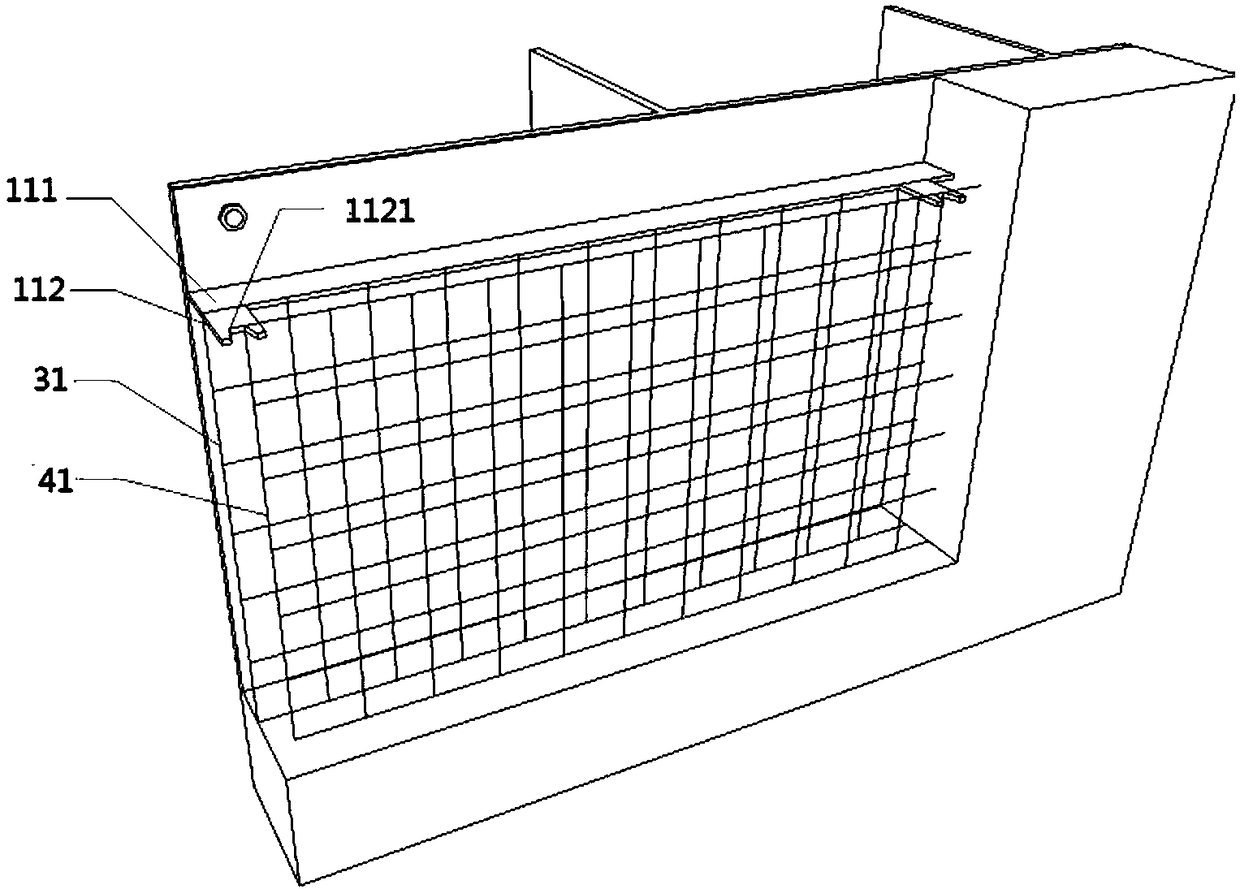

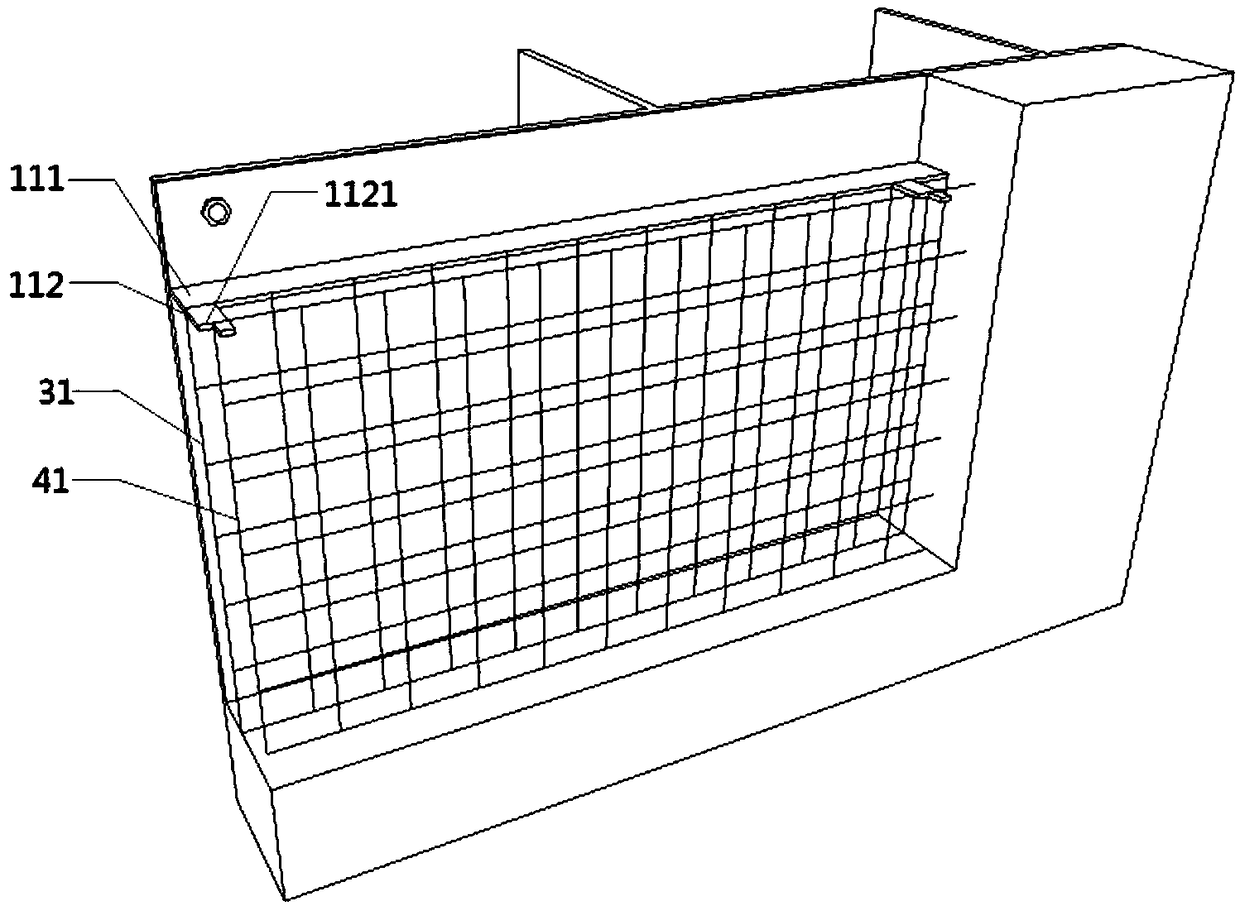

[0040] Such as Figure 1-5 As shown, the present invention provides a steel structure exterior wall insulation mortar enclosure system with anchors. The steel structure exterior wall insulation mortar enclosure system includes an interface mortar layer 2 arranged on the base wall 1. The bottom heat insulating mortar layer 3 on the interface mortar layer 2, the middle heat insulating mortar layer 4 arranged on the bottom heat insulating mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com