Prefabricated part butt joint interface quality detection and treatment method

A technology of prefabricated components and disposal methods, which can be applied to measuring devices, building structures, optical devices, etc., and can solve problems such as difficult assembly accuracy and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

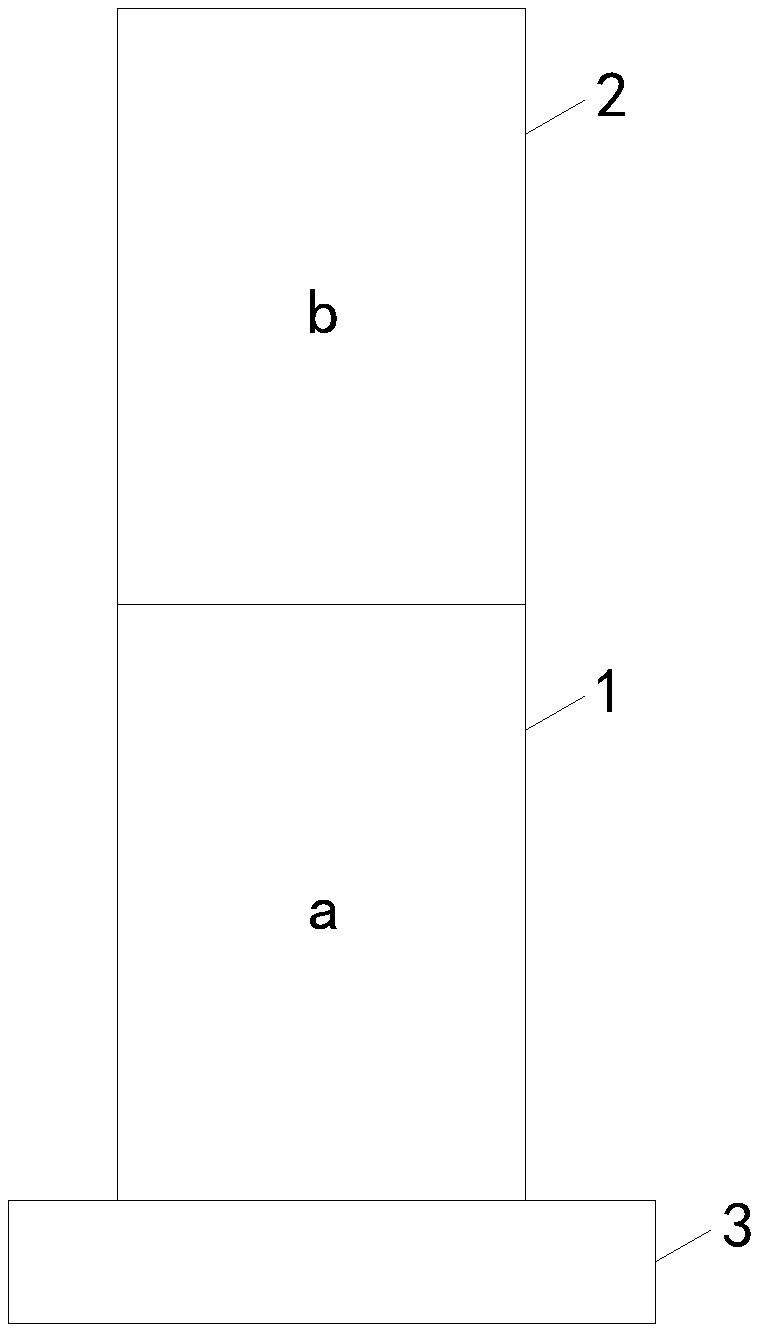

[0033] Example one: figure 1 Shown is the assembly design of two concrete prefabricated components. The first prefabricated component a at the lower part is connected to the bottom plate 3, and the second prefabricated component b at the upper part is vertically aligned and connected with the first prefabricated component a, and the bottom is combined Figure 1 to Figure 5 Explain the quality detection and treatment method of the docking interface of the prefabricated component of the present invention, and the specific steps are as follows:

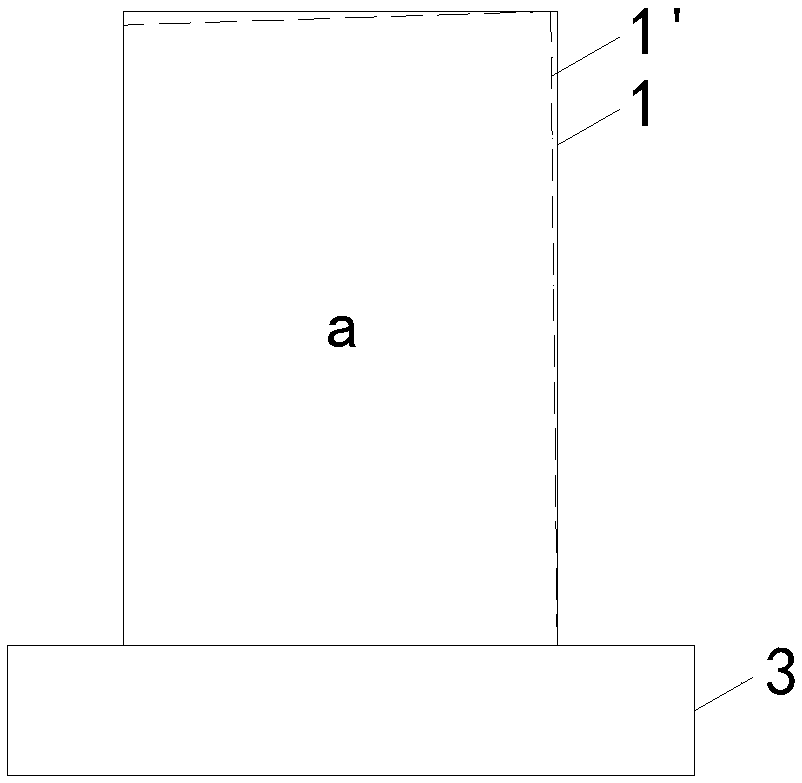

[0034] S1: Perform a three-dimensional scan of the first prefabricated component a installed on the bottom plate 3 at the construction site, and send the three-dimensional scan data to a background processing system (not shown in the figure), and the background processing system generates the first prefabricated component based on the three-dimensional scan data The actual three-dimensional graphics 1';

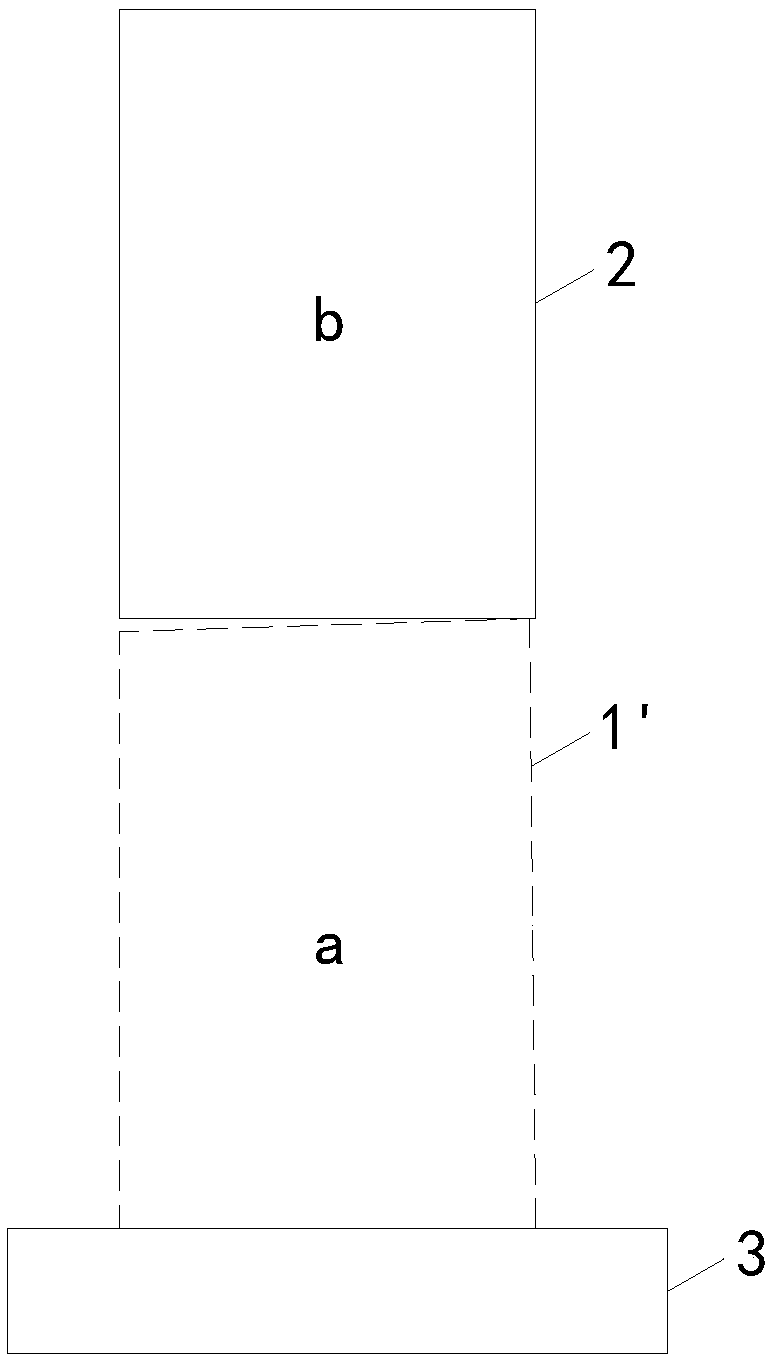

[0035] S2: Such as image 3 As shown, ...

Embodiment 2

[0039] Embodiment 2: Combination Figure 1-Figure 4 , Figure 6-Figure 8 Describe the quality detection and treatment method of the prefabricated component docking interface of the present invention. The difference from the first embodiment is that after the second prefabricated component b is processed according to the adjustment parameters given by the background processing system, the second prefabricated component b docking interface When the flatness still cannot meet the assembly design requirements, the specific steps of the method are as follows:

[0040] S11: Perform a three-dimensional scan of the first prefabricated component a installed on the bottom plate 3 at the construction site, and send the three-dimensional scan data to the background processing system, which generates the actual three-dimensional graphics 1'of the first prefabricated component according to the three-dimensional scan data, Such as figure 2 Shown, comparative analysis of the design model of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com