Two-dimensional code scanner fixing device for production line

A technology of two-dimensional code scanners and fixing devices, which is applied in two-dimensional code-related fields, can solve problems such as inconvenient maintenance, reduced work efficiency, troublesome lifting devices, etc., and achieves the advantages of easy disassembly and installation, improved maintenance efficiency, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

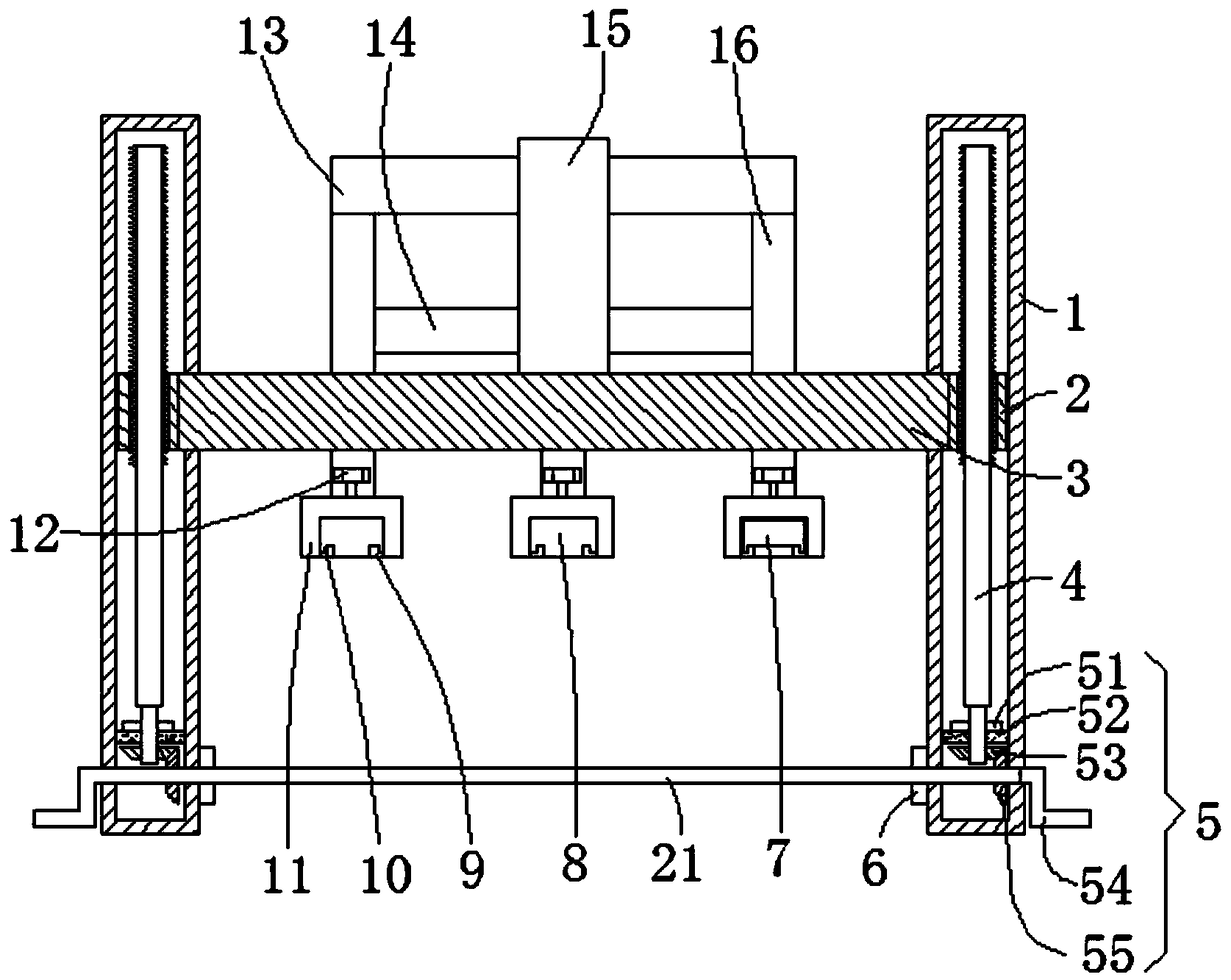

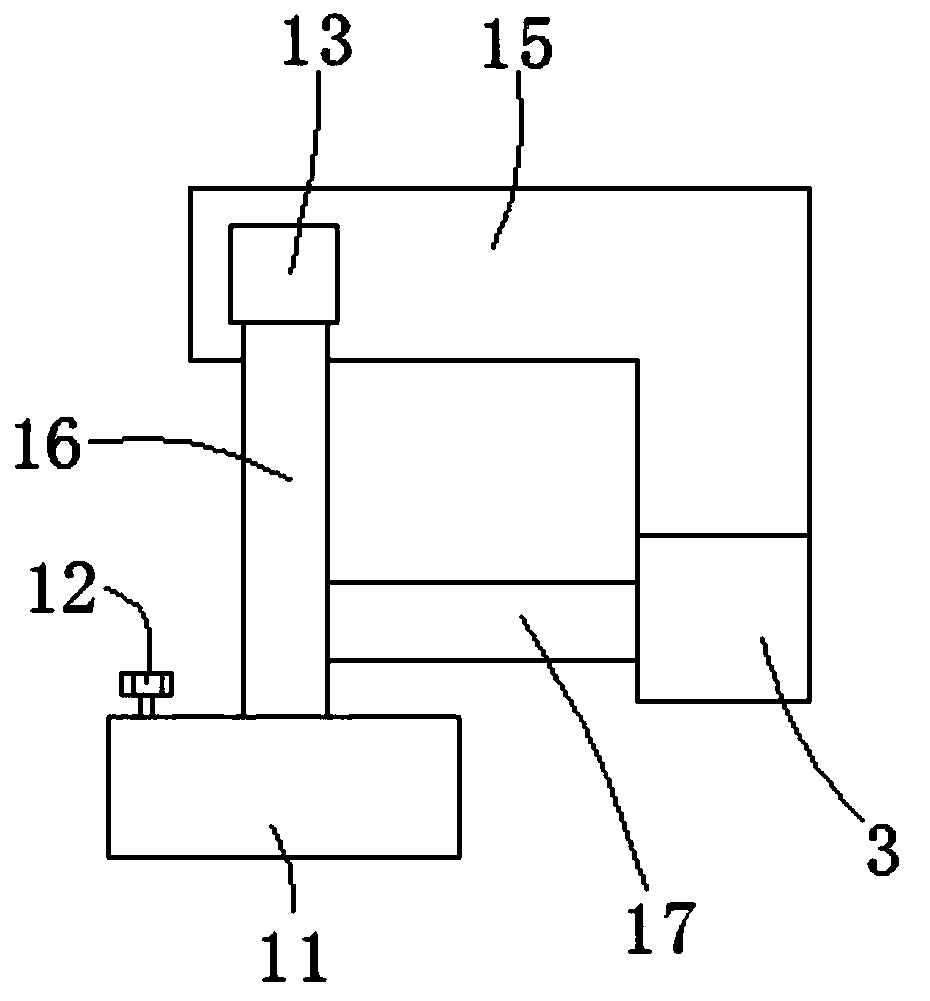

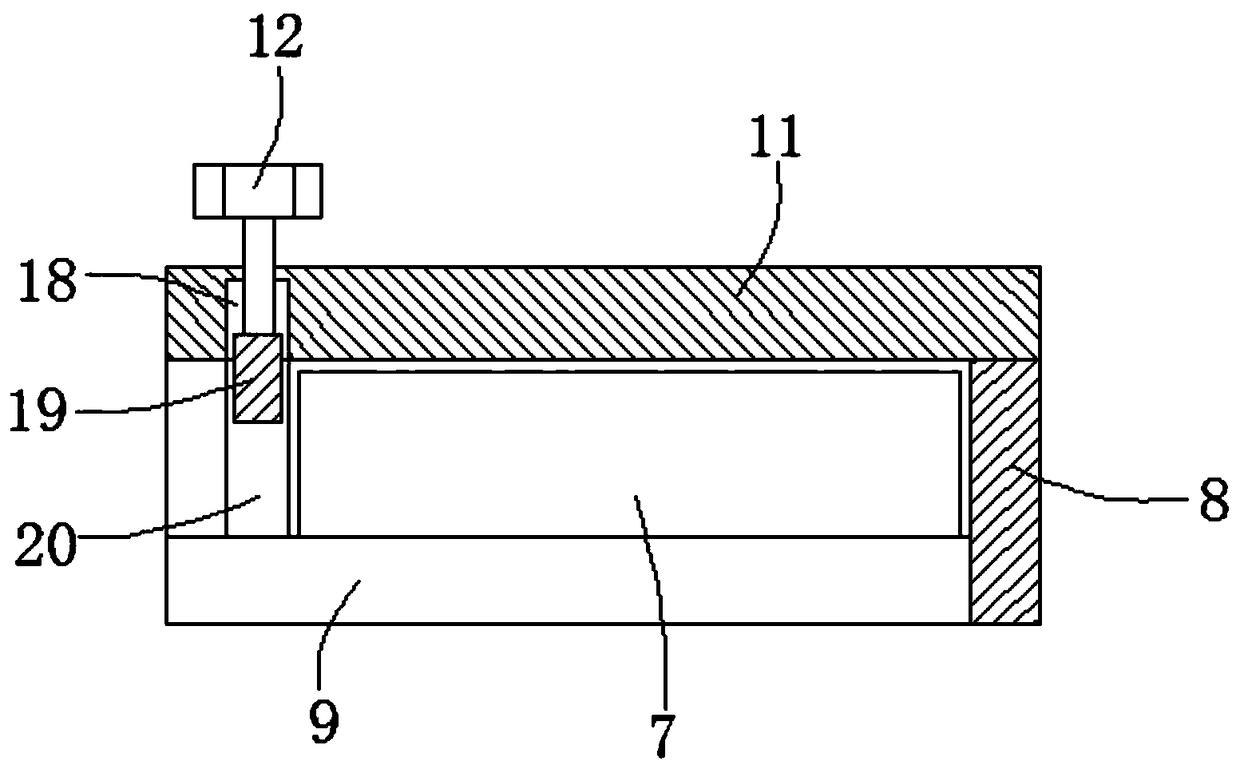

[0019] see Figure 1-3 , the present embodiment provides a two-dimensional code scanner fixing device for a production line, including two first support plates 1 and a lifting platform 3, both of the first support plates 1 are hollow structures, and the bottom ends are fixedly installed with The lifting adjustment mechanism 5 is fixedly connected between the two lifting adjustment mechanisms 5 through the second rotating rod 21, the tops of the two lifting adjusting mechanisms 5 are fixedly connected with the first rotating rod 4, and the left and right ends of the lifting platform 3 are fixedly connected There are sliders 2, and the two sliders 2 are slidingly connected with the two first rotating rods 4 respectively. The upper ends of the two first rotating rods 4 are threaded for half the length, and the end faces of the two sliders 2 are provided with The threaded hole matched with the thread, the center position of the top surface of the lifting platform 3 is fixedly conn...

Embodiment 2

[0022] see figure 1 A further improvement is made on the basis of Embodiment 1: the lifting adjustment mechanism 5 includes a second bevel gear 55 fixedly socketed with the second rotating rod 21 and a first bevel gear 53 fixedly socketed with the first rotating rod 4, The lifting adjustment mechanism 5 includes a limiting plate 51, a dividing plate 52 and a rotating handle 54. The dividing plate 52 is fixedly connected with the inner cavity of the first supporting plate 1, and the lower end of the first rotating rod 4 passes through the limiting plate 51, the dividing plate 52 and the The first bevel gear 53 is fixedly connected with the limiting plate 51 and the first bevel gear 53 , and the rotating handle 54 is fixedly connected with the end surface of the second rotating rod 21 . When it is necessary to lift the scanner main body 7, turn the rotating handle 54 clockwise, the rotating handle 54 drives the second rotating rod 21 to rotate clockwise, and drives the second be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com