Heat transfer oil boiler steam generating system capable of changing physical and chemical properties of water

A heat-conducting oil boiler and generation system technology, which is applied in the steam generation method using heat carrier, etc., can solve the problems of large equipment, large heat energy loss, and low steam generation efficiency, and achieve small volume, short vaporization time, and improved steam generation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

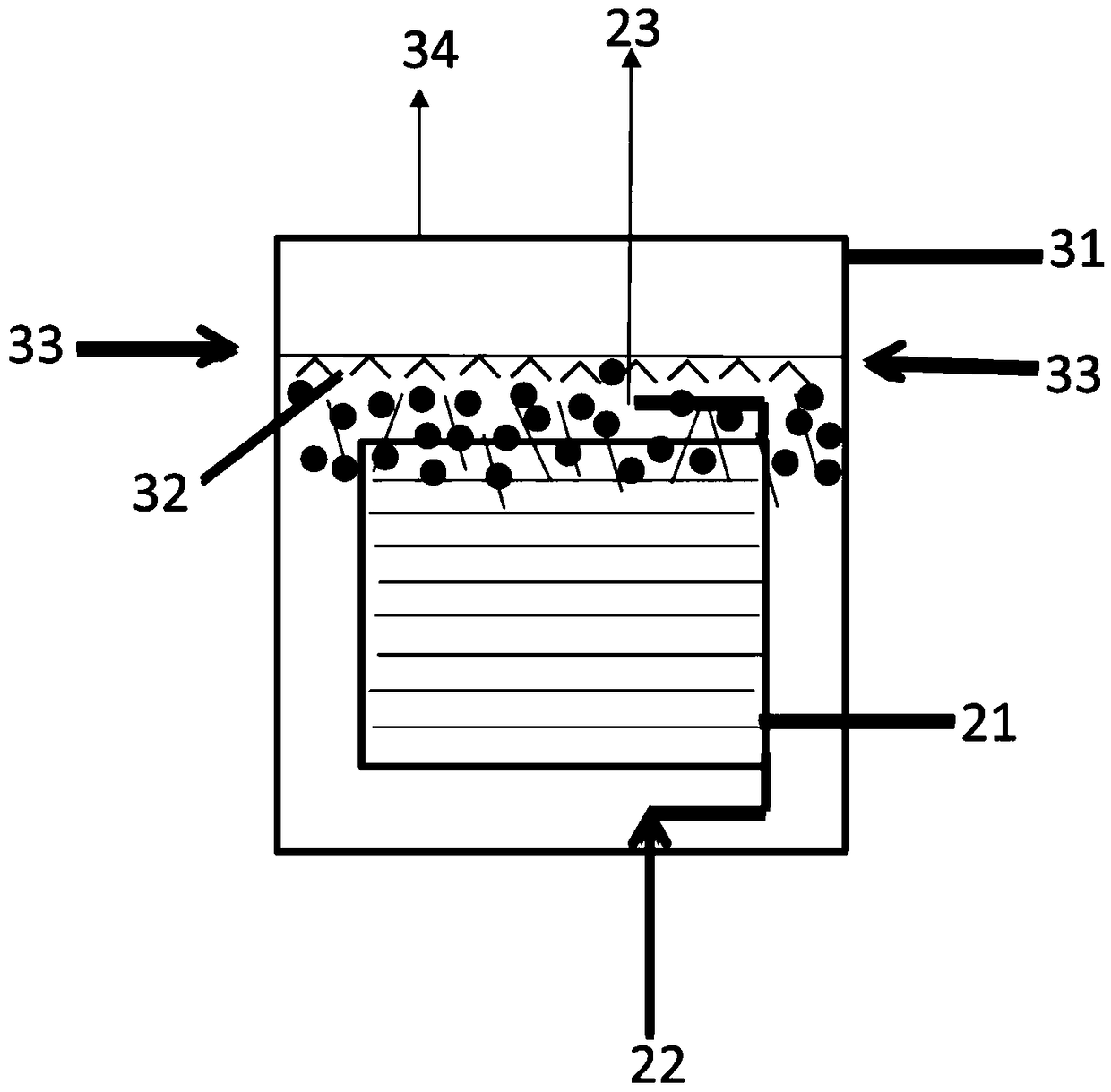

[0016] Combine below Figure 1 to Figure 2 The preferred embodiments of the present invention are further described:

[0017] Such as figure 1 As shown, the heat-conducting oil boiler steam generation system for changing the physical and chemical characteristics of water disclosed in the present invention includes a heating burner 1, which is connected to a heat-conducting oil heat exchanger 2 correspondingly, and the heat-conducting oil exchanges heat The device 2 communicates with the steam generator 3 correspondingly, and the steam generator 3 also communicates with the small molecule water generator 4 correspondingly. The heat supply burner of the present invention provides heat for the heat transfer oil heat exchanger, the heat transfer oil in the heat transfer oil heat exchanger transfers the heat to the steam generator, and the small molecule water generated by the small molecule water generator enters the steam generator and absorbs heat conduction The heat of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com