Dust removing powder material drying box

A technology for powder materials and drying boxes, which is applied in drying, drying machines, drying solid materials, etc., and can solve problems affecting the life of components in the drying box, powder falling out, and prolonging drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

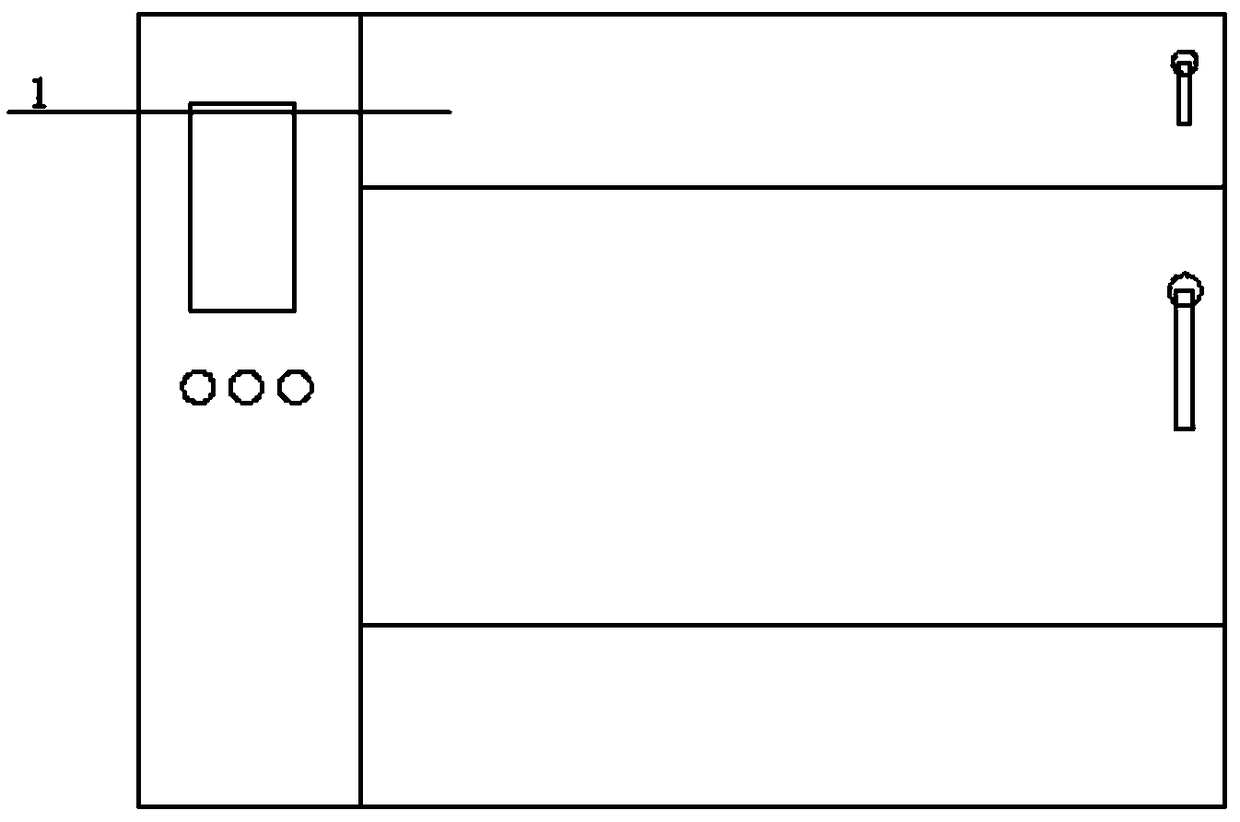

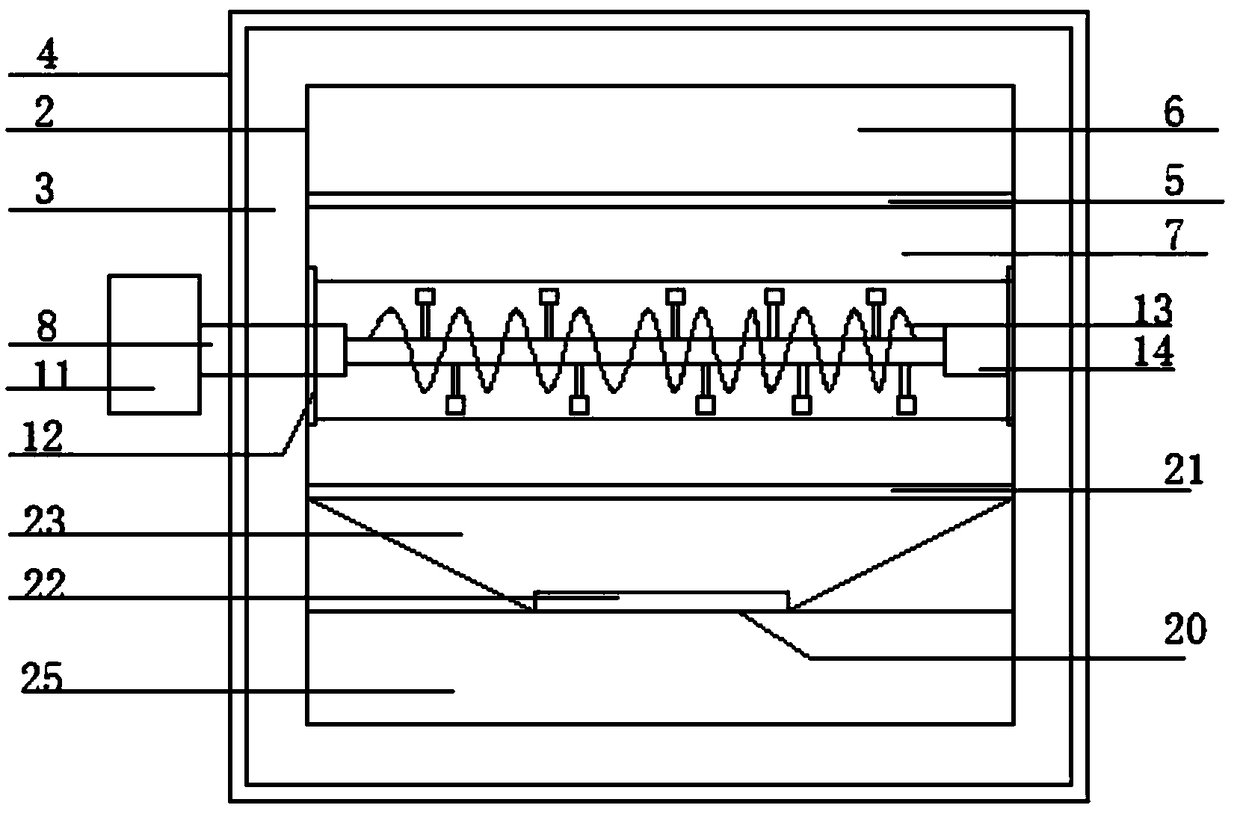

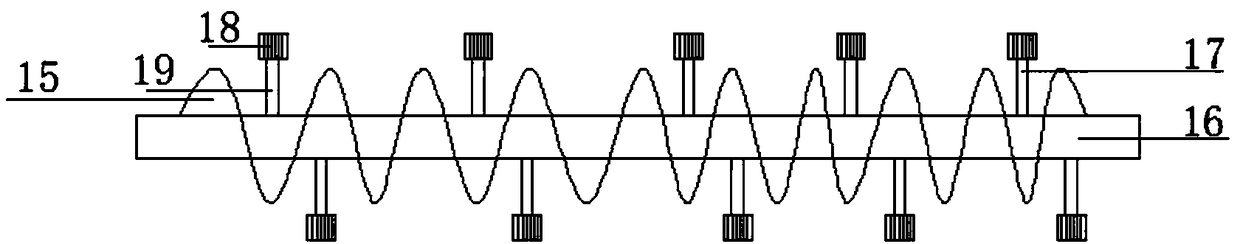

[0029] Such as figure 1 As shown, a dust removal powder material drying box includes a drying box shell 4, an insulating layer 3, a tank liner 2 and a door body 1; the drying box shell 4 is at the outermost layer, and the insulating layer 3 Sandwiched between the tank 2 and the drying box shell 4, the tank 2 forms a drying space; the drying space is divided into three layers, and the uppermost layer is a test block placement area 6, which is separated by a partition 5. The separator 5 is a stainless steel metal mesh plate, which is used to place the test block. In the middle is a bulk powder placement area 7 for placing bulk powder. The bottom layer is a dust collection area 10 for collecting dust. Such as figure 2 As shown, there is no partition 5 between the dust collection area 10 and the bulk powder storage area 7 . The bulk powder storage area 7 is provided with a powder bucket 9 and a main shaft 8, the main shaft 8 is connected with a motor 11 outside the drying box...

Embodiment 2

[0035] Such as figure 1 As shown, a dust removal powder material drying box includes a drying box shell 4, an insulating layer 3, a tank liner 2 and a door body 1; the drying box shell 4 is at the outermost layer, and the insulating layer 3 Sandwiched between the tank 2 and the drying box shell 4, the tank 2 forms a drying space; the drying space is divided into three layers, and the uppermost layer is a test block placement area 6, which is separated by a partition 5. The separator 5 is a stainless steel metal mesh plate, which is used to place the test block. In the middle is a bulk powder placement area 7 for placing bulk powder. The bottom layer is a dust collection area 10 for collecting dust. There is no partition 5 between the dust collection area 10 and the bulk powder storage area 7 . The bulk powder storage area 7 is provided with a powder bucket 9 and a main shaft 8, the main shaft 8 is connected with a motor 11 outside the drying box, and the motor 11 drives the...

Embodiment 3

[0040] Such as figure 1 As shown, a dust removal powder material drying box includes a drying box shell 4, an insulating layer 3, a tank liner 2 and a door body 1; the drying box shell 4 is at the outermost layer, and the insulating layer 3 Sandwiched between the tank 2 and the drying box shell 4, the tank 2 forms a drying space; the drying space is divided into three layers, and the uppermost layer is a test block placement area 6, which is separated by a partition 5. The separator 5 is a stainless steel metal mesh plate, which is used to place the test block. In the middle is a bulk powder placement area 7 for placing bulk powder. The bottom layer is a dust collection area 10 for collecting dust. There is no partition 5 between the dust collection area 10 and the bulk powder storage area 7 . The bulk powder storage area 7 is provided with a powder bucket 9 and a main shaft 8, the main shaft 8 is connected with a motor 11 outside the drying box, and the motor 11 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com