High-power LED optical fiber coupling system

A fiber-optic coupling and high-power technology, applied in the field of high-power LED fiber-optic coupling systems, can solve the problems of being unable to adapt to manual control of lighting, large power supply and heat dissipation systems, etc., to achieve improved LED beam utilization, reasonable structure, and suitable for popularization and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

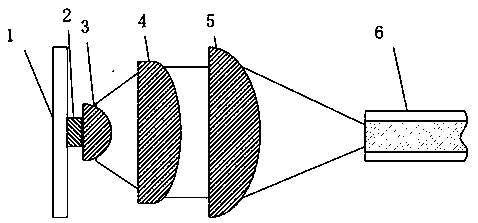

[0013] Specific embodiment one, please refer to figure 1 , a high-power LED optical fiber coupling system, comprising an LED cooling base plate 1, an LED chip 2, a first lens 3, a second lens 4, a third lens 5 and an optical fiber bundle 6, one side of the LED chip 2 is fixed on the LED On the heat dissipation base plate 1, the other side of the LED chip 2 is close to the incident surface of the first lens 3, and the outside of the first lens 3 is provided with a second lens 4, a third lens 5 and an optical fiber bundle 6 in sequence, The second lens 4 can form the beam converged by the first lens 3 into a parallel beam and emit it. The third lens 5 can focus the parallel beam emitted by the second lens. The incident end surface of the optical fiber bundle 6 is located at the third lens 5 The focal position of the third lens 5 at the focal position is smaller than the aperture of the optical fiber bundle 6, and the converging angle of the beam passing through the third lens 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com