High-speed RVS cable single twisting machine

A single twisting machine and cable technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of increasing human resources investment, increasing production capacity input costs, increasing equipment investment costs, etc., to reduce labor intensity, The effect of reducing human resource input costs and proper facility layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

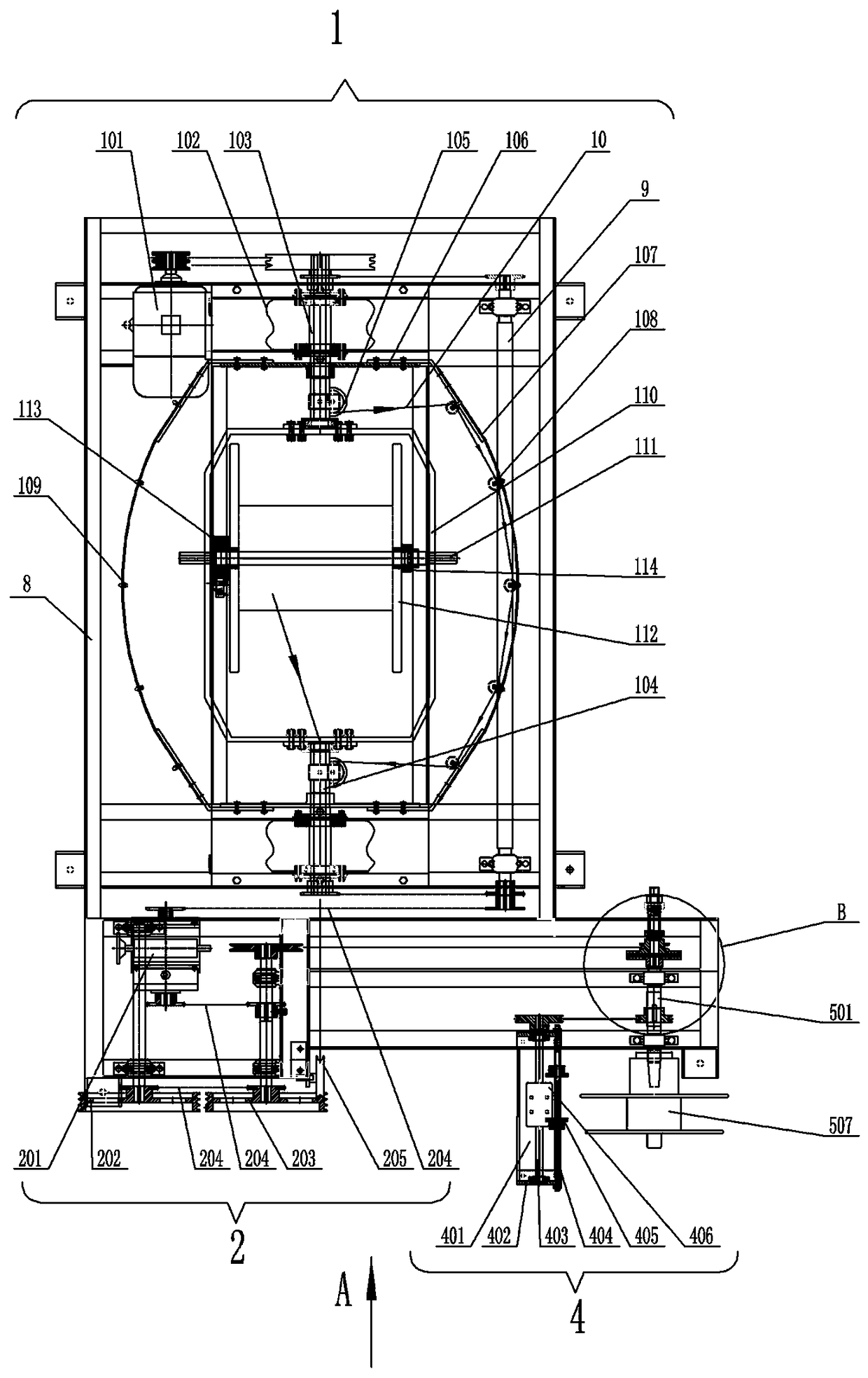

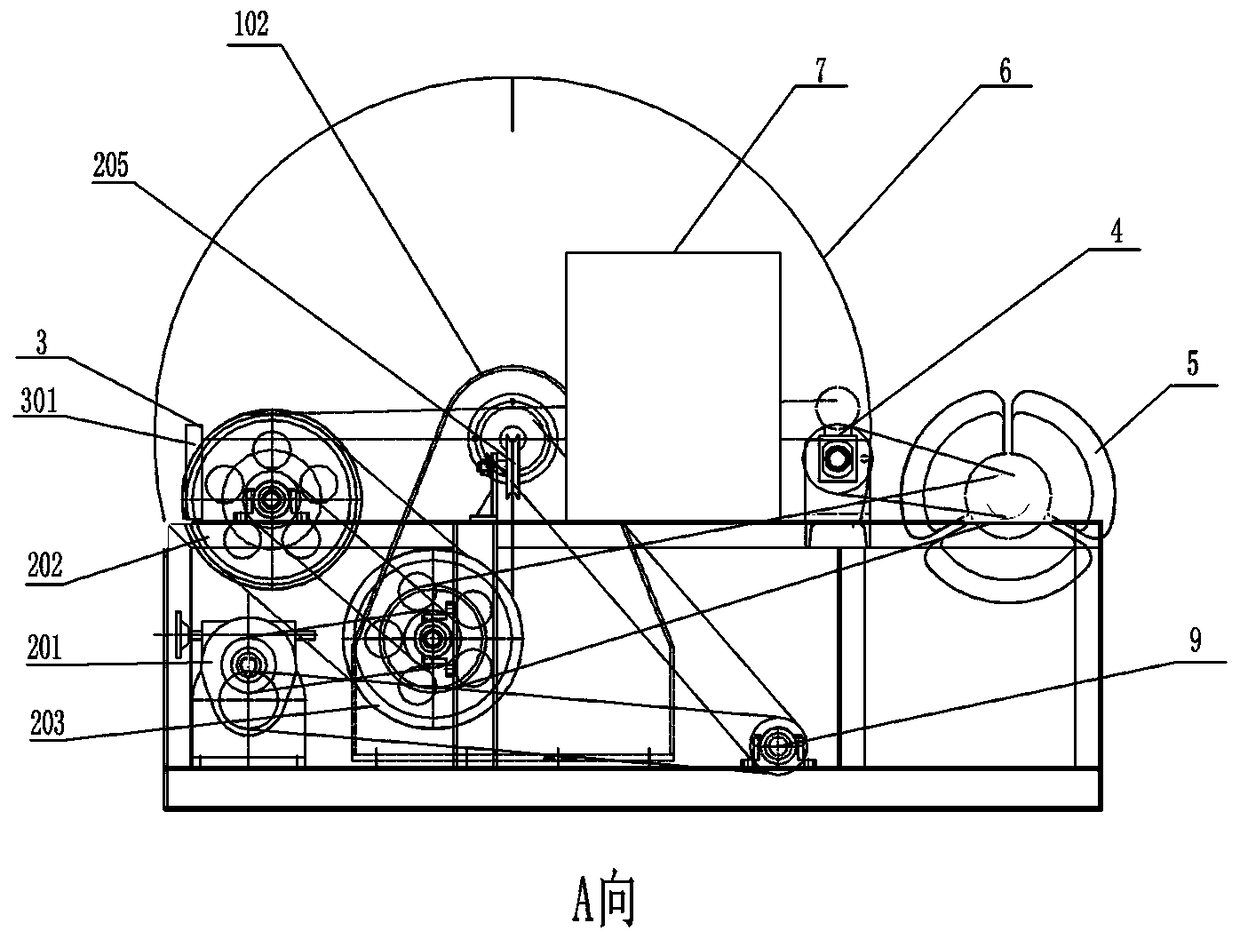

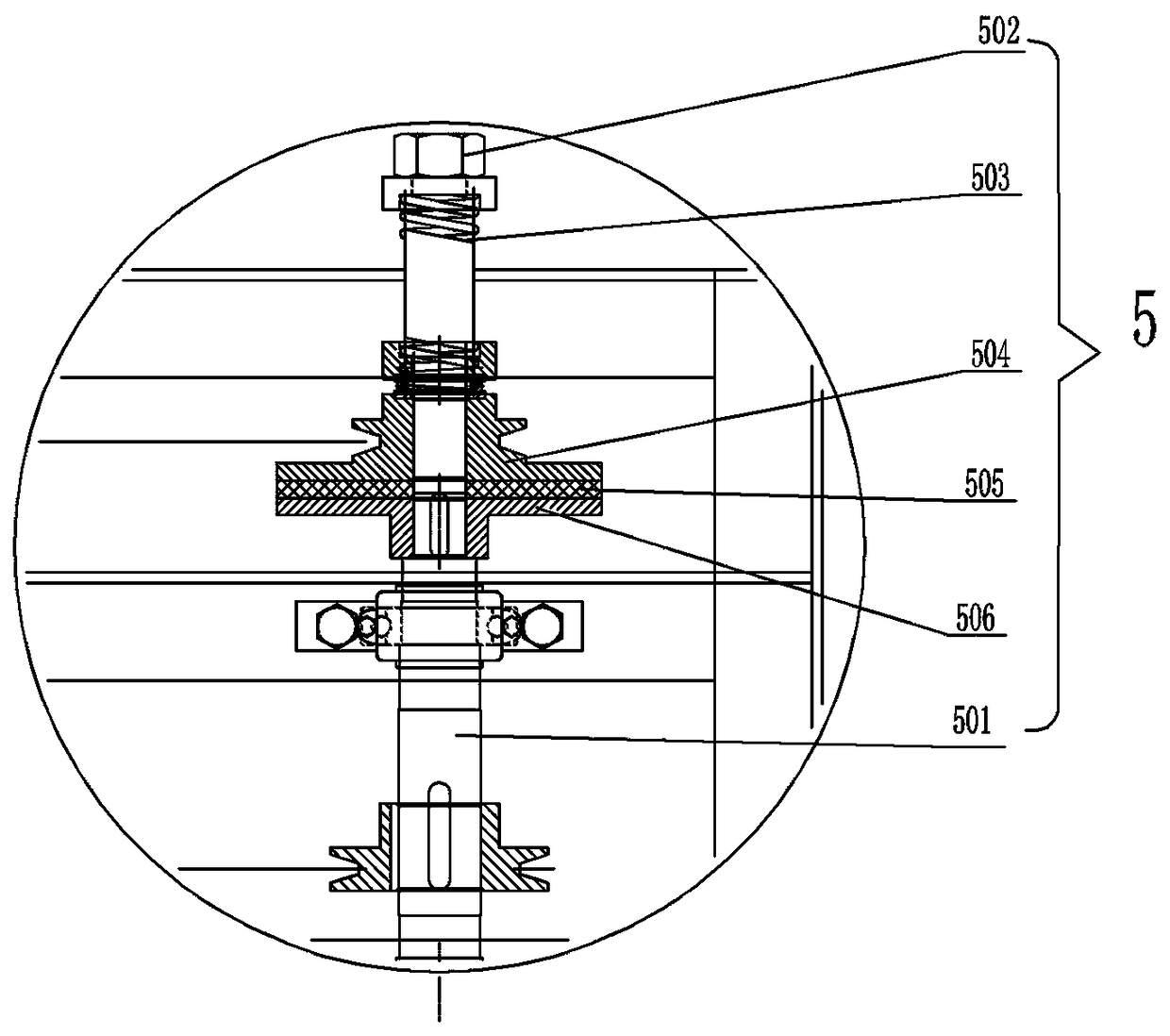

[0030] The high-speed RVS cable single twisting machine of the present invention includes a shared frame 8, on which a twisted wire assembly 1, a traction assembly 2, a wire arrangement assembly 4 and a wire take-up assembly 5 are sequentially arranged in accordance with the routing sequence, and the The stranded wire assembly 1 is arranged on one end of the shared frame 8, and the traction assembly 2 is arranged on the other end on the shared frame 8, on the outlet side of the stranded wire assembly 1; On the shared frame 8 on the side; the cable assembly 4 is arranged on the shared frame 8 between the traction assembly 2 and the take-up assembly 5; the shared frame 8 between the traction assembly 2 and the cable assembly 4 There is also a power distribution control cabinet 7;

[0031] The twisted wire assembly 1 includes a twisted wire motor 101 arranged on a shared frame, two box frames 102 whose coaxial lines are arranged in parallel on the base of the shared frame 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com