camera module

A camera module and circuit board technology, which is applied in the directions of image communication, television, and printed circuits connected with non-printed electrical components, can solve problems such as size reduction and structural limitations, avoid virtual welding, and avoid high and low inconsistencies. the effect of one

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

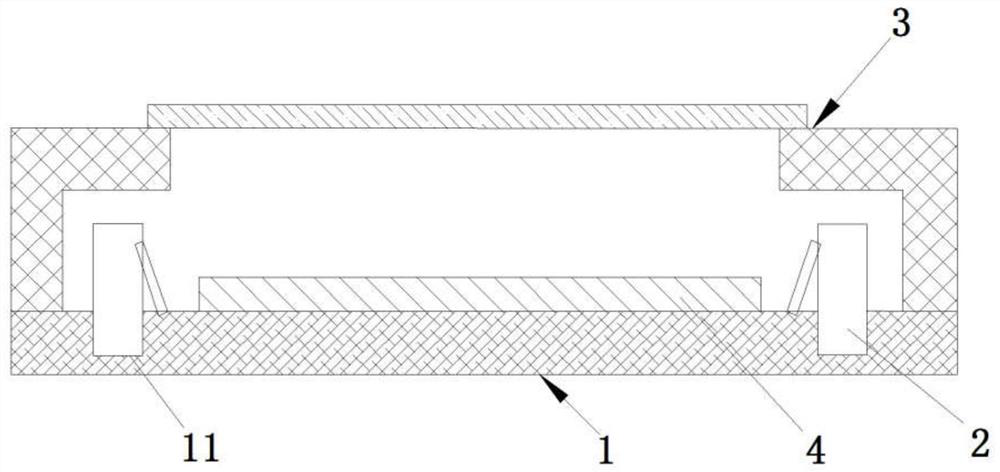

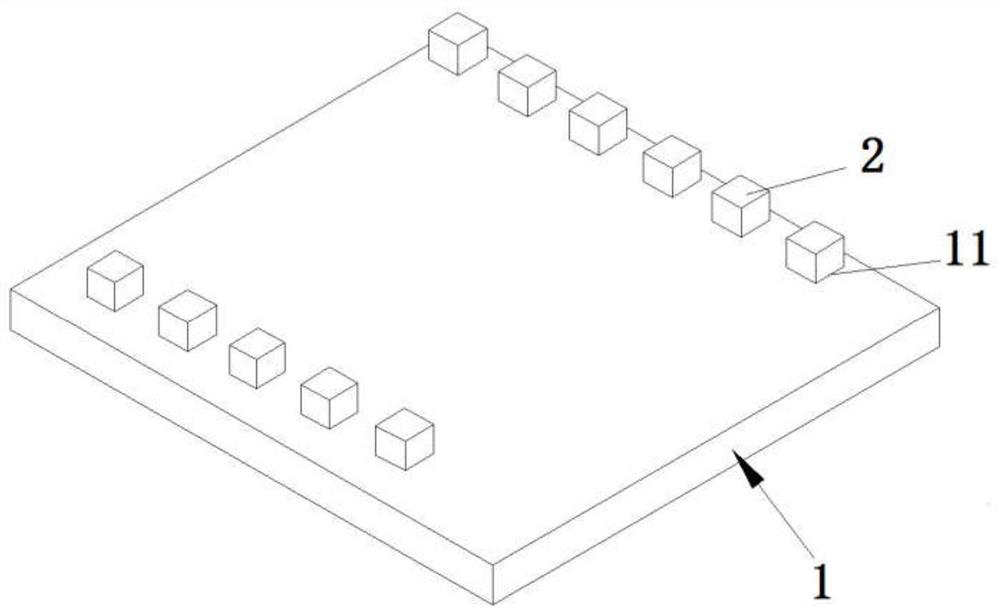

[0027] figure 1 is a front view schematically showing a camera module according to an embodiment of the present invention. As shown in the figure, according to an embodiment of the present invention, the camera module includes a circuit board body 1 , components 2 , a main body 3 and a chip 4 . In this embodiment, both the main body 3 and the chip 4 are supported on the upper surface of the circuit board body 1 . The main body 3 is a cylinder with a cavity, which can be fixed and supported on the circuit board body by bonding, fitting, etc. The main body 3 contains both the components 2 and the chip 4 in its cavity, and the main body 3 also needs to be supported The imaging unit (not shown in the figure) thus constitutes a complete camera module. At the same time, the components 2 and the chip 4 also need to be electrically connected to the circuit board body. In this embodiment, the component 2 may use a capacitor.

[0028] figure 2 yes figure 1 Schematic diagram of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com